So i've "found" a Cherry / Compaq G80 11800 in our server room, not used anymore. I remember typing on this device before being keyboard addicted - but only a little bit when there was a real problem which could not be solved with remote connection. I don't really know what to do, but i love the bottom-out sound of these brown switches, and could use many of the Skidata keycaps on it, maybe make some weird switch combinations and playing with a Teensy.

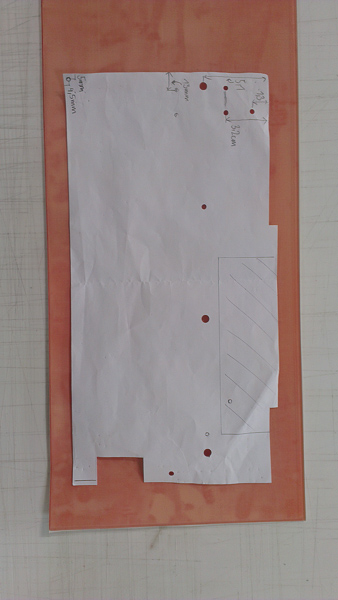

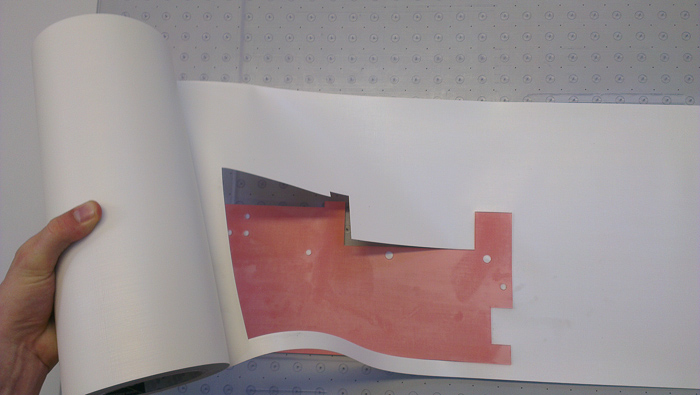

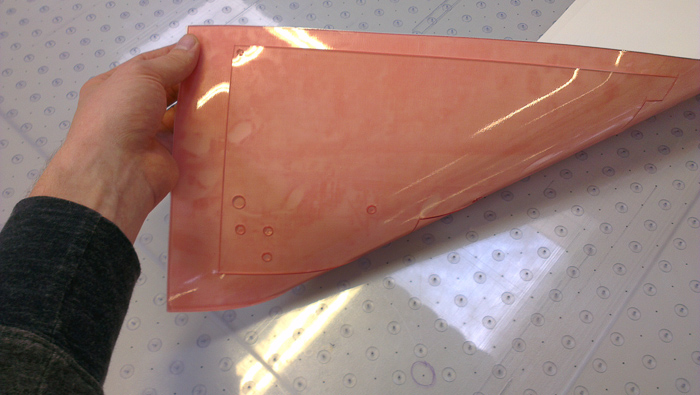

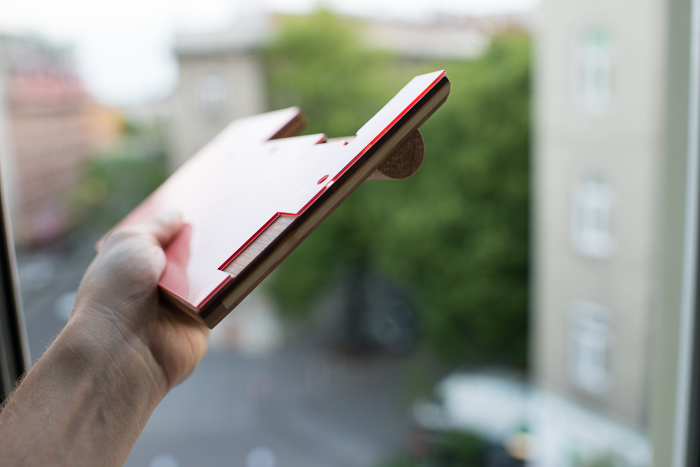

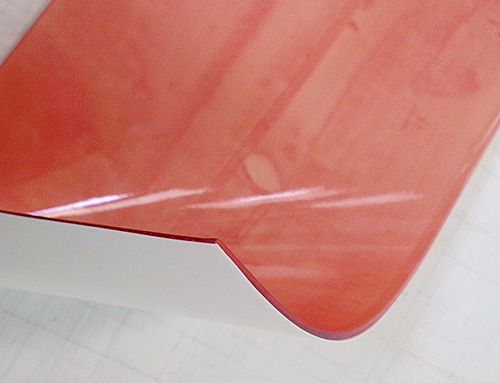

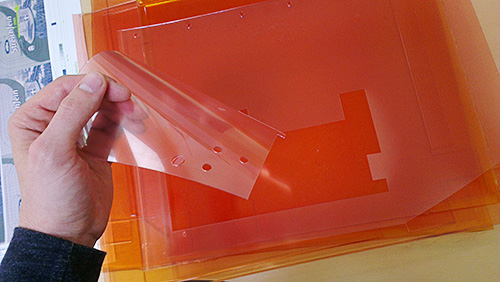

I have not cleaned anything, and want to fix the board on a piece of wood. I've already cut two pieces today, one the full length, and one width without the ten-keys. I don't know yet, if i should make a TKL out of it! It looks very clean on the back, and just two arrow keys go through the ten-key numbers, but i would not really know what to do (but read the other TKL selfmade threads here).