The pad card had a ton of crud on it. IPA to the rescue.

- D72_2124.jpg (850.33 KiB) Viewed 9363 times

Switches exposed

- D72_2127.jpg (867.36 KiB) Viewed 9363 times

Nasty foam, as is normal for IBM...

- D72_2130.jpg (942.51 KiB) Viewed 9363 times

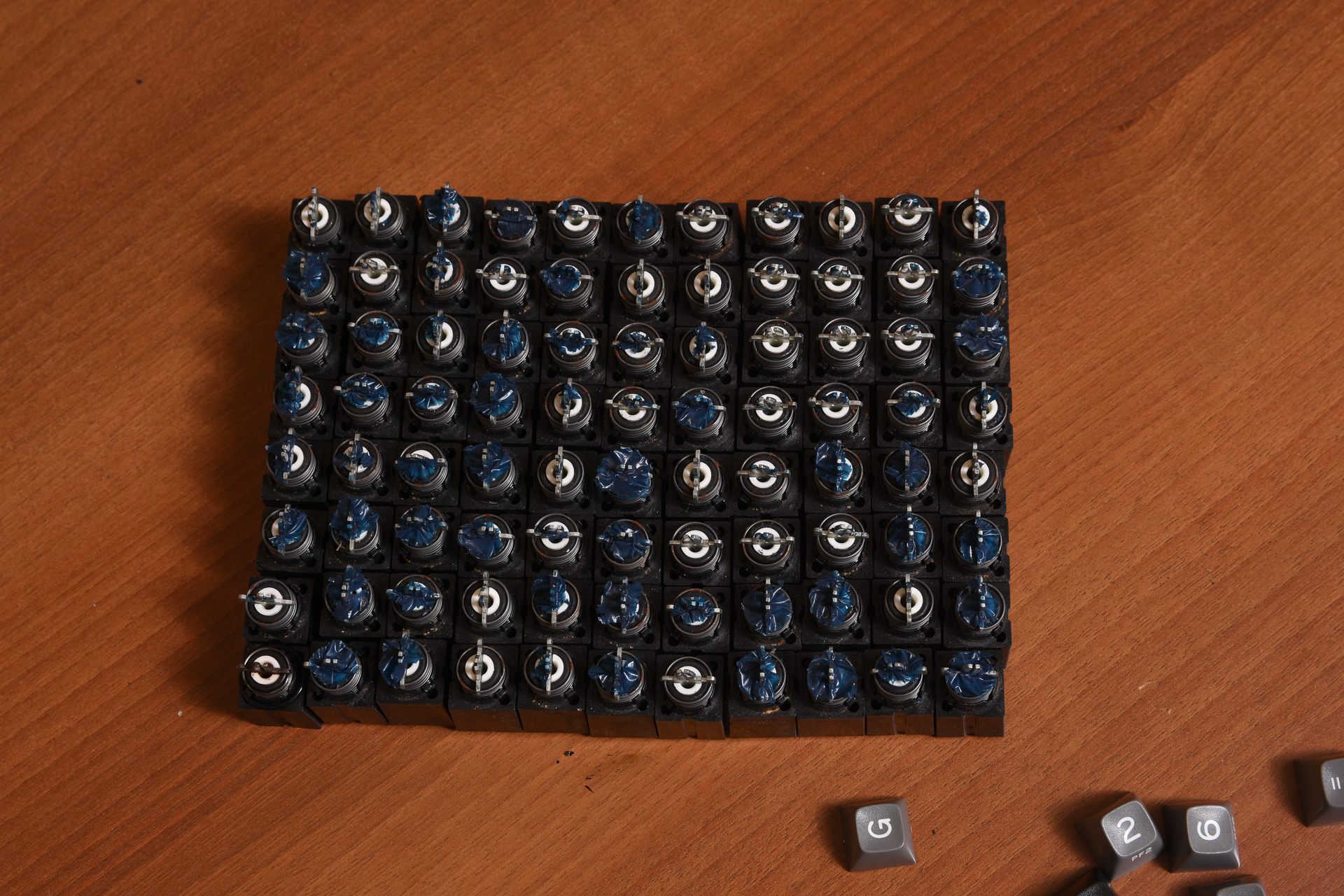

All switches removed and lined up!

- D72_2132.jpg (905.1 KiB) Viewed 9363 times

At this point everything got a bit messy, so I have no pics of the actual cleaning, but the case and the switch "cage" were washed and scrubed with a brush and hand soap.

I didn't go crazy on the case, as there is quite a bit of deep-embeded dirt, and it was already flaking in some spots.

Meanwhile the caps got a good soak and cleaning with a toothbrush.

- D72_2131.jpg (765.72 KiB) Viewed 9363 times

I removed the orings from the switches to clean and lubricate them.

- D72_2138.jpg (809.2 KiB) Viewed 9363 times

Washed and soaked in just a bit of silicone oil.

- D72_2140.jpg (878.83 KiB) Viewed 9363 times

I cleaned the stems from the contamination shield remains with and eraser and a brass brush.

- D72_2136.jpg (940.17 KiB) Viewed 9363 times

A few springs were a bit rusty, so in the rust converter they go.

- D72_2142.jpg (919.56 KiB) Viewed 9363 times

You can easily remove them by "screwing" them off.

- D72_2141.jpg (646.88 KiB) Viewed 9363 times

The rusty stem also got treated and it was quite pitted.

It was a bitch to remove, I tried WD40, silicone oil, pulling, cursing, everything. In the end a tiny bit of heating with a lighter made it release.

After this shot it got another tour in the cup of rust converter.

- D72_2144.jpg (887.61 KiB) Viewed 9363 times

IBM's selection of foam was quite stupid. Even stupider than rivets on the M.

These are the glue backing remains of the foam layer.

- D72_2146.jpg (817.25 KiB) Viewed 9363 times

Plate remounted upsider down for switch placement.

- D72_2147.jpg (831.97 KiB) Viewed 9363 times

Instead of making new foam, I tried another solution. I used #15 o-rings on each switch.

I had plenty (widely used in paintball) and it was easy enough so I gave it a try. The black one is Buna-N 70A Durometer (used 84) and the clear is urethane (90A IIRC, used 4)

- D72_2150.jpg (855.1 KiB) Viewed 9363 times

Switches ready for action!

- D72_2151.jpg (785.68 KiB) Viewed 9363 times