Page 5 of 6

Posted: 15 Feb 2018, 20:32

by faxe

Another question regarding PCB, the KBDFans will be available with USB-C soon(ish), does the case work with that as well?

Posted: 15 Feb 2018, 22:34

by PlastikSchnittstelle

Oh you're right,

this one, hadn't noticed it jet.

Shouldn't be a problem. The connector is at the same place. Although USB-C is a smaller connector than Mini-USB, sometimes the part behind the actual connector - that where you hold it (sorry, don't know how to describe it else) sometimes looks huge on USB-C cables. So just make sure your USB-C cable doesn't have a "bulky head". Other differences compared to the previous version of the 75% PCB seem to be the holes for the standoffs - but we don't have to care about this at all, since this would only be a concern for tray mount cases. So short: the PCB will fit perfectly fine.

Looks like the rev.2 supports some more layouts as well. I will look into this...

...yes,

now with split spacebar support. I'll update the plate to support it as well.

Posted: 25 Feb 2018, 19:56

by RealLaugh

do you know when you'll receive the samples or are there any updates on this one?

Posted: 26 Feb 2018, 11:44

by PlastikSchnittstelle

Still don't have the samples.

I'll ask again today, so hopefully I'll know soon.

Sorry, it is terrible for me as well, that this is dragging on for so long now.

Posted: 27 Feb 2018, 15:58

by PlastikSchnittstelle

small update.

I'll get the samples in mid march. so roughly two more weeks waiting.

Posted: 15 Mar 2018, 14:04

by PlastikSchnittstelle

OK, I was informed that I can pick up the samples next Tuesday or Wednesday.

FINALLY!

Posted: 15 Mar 2018, 15:44

by scl

cant wait for pics

Posted: 15 Mar 2018, 16:29

by DarKou

Great news!

Posted: 22 Mar 2018, 23:05

by PlastikSchnittstelle

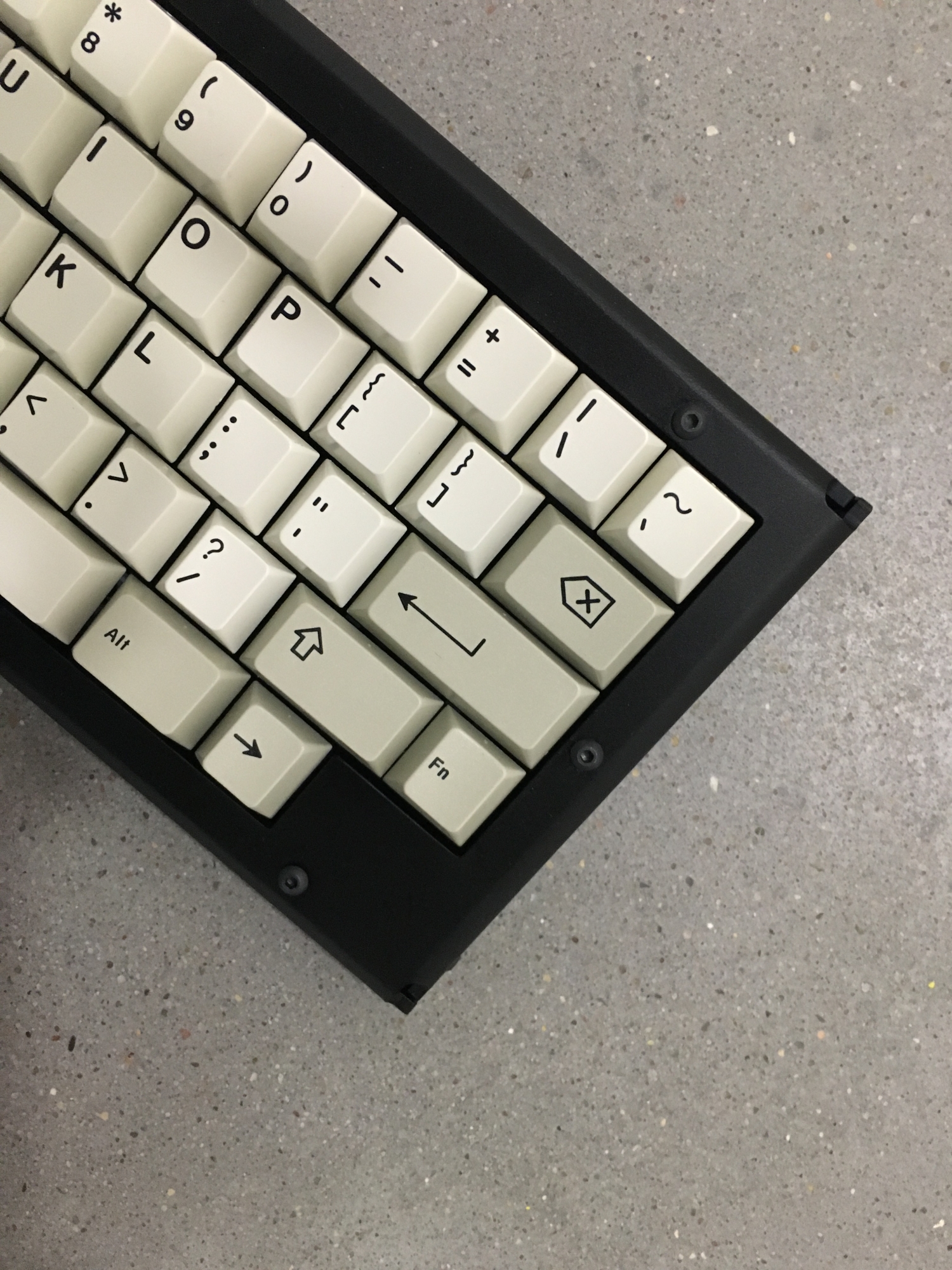

Finally got the samples on Wednesday!

Big relief, everything is fine and fits.

The plan was to only show you the samples after I finished a nice build and took superduper DSLR pictures. But now I feel like I don't wanna let you wait any longer and it might take at least another week until I have DSLR pics. Also someone told me he thinks that quick n dirty mobile pics are more honest and trustworthy. At least I finished the build today.

Though there is one changes I want for GB production. The bead blasting is too fine, I want it to be much rougher. Good thing I made the samples.

Components:

- standard GH60 satan PCB from kbdfans

- Cherry MX-Silent-Blacks (with real MX-Black springs, not the ones from the GB with the lighter springs)

- GMK ISO Dolch set from a German GB (were on the 65% prototype before)

- Cherry stabs harvested from old G80s (made the 6U wire from a 7U)

- obviously my case, the SKB60 (angle at 10 degree)

So here is one:

and here are more:

https://imgur.com/a/5wfjv

Posted: 22 Mar 2018, 23:12

by RealityCavesIn

Looks great!

Posted: 22 Mar 2018, 23:16

by snoopy

very nice! love that it kind of has an industrial look

Posted: 23 Mar 2018, 01:10

by Ail

Looks awesome, might have to go in on a 75%.

Posted: 23 Mar 2018, 08:15

by DarKou

Looks really great.

This is the final screw? Or you will use some others screws like this:

https://www.bricovis.fr/std/prod/tfhc/TFHCEF.png

Posted: 23 Mar 2018, 10:11

by Shihatsu

This is exactly what I have in mind for mine, with the exception of going for the 70%.

Where did you get the switches from? I definately want to go Silent Black, but I love my hard springs, do I have to build the switches by myself? I also have absolute zero stabs... We need an "Einkaufskorb" with links for all the goods we will need

Edit: O, and I have forgotten the core of my post: This looks GREAT!

Posted: 23 Mar 2018, 10:16

by faxe

Looking very good! Good call on rougher sandblasting! Looking forward to this!

Posted: 23 Mar 2018, 11:30

by RealLaugh

Looks so good, can't wait for the GB and can't decide if standard 60% or WKL...but anyway great job on the Proto it looks great! Would be interested to get an idea of weight on your finished build and also maybe get a typing test to hear how it sounds.

Posted: 27 Mar 2018, 14:27

by PlastikSchnittstelle

The weight is: 0.970 kg

for comparison, my Pok3r weighs 0.802 kg

Posted: 27 Mar 2018, 14:38

by PlastikSchnittstelle

Yesterday I made a second build from the samples I got. This time the HHKB version. Wanted this to be a perfect build so it took quite some time,

here is the IMGUR album.

Here a little teaser:

- SKB60-sample-HHKB (00).jpg (1.76 MiB) Viewed 13447 times

After I finished the build late at night yesterday, I noticed

wodan had put up a stream. I found this to be quite ironic. While he was having fun with his new hightech soldering iron, I was desoldering and soldering with cheap amazon stuff

Posted: 27 Mar 2018, 15:16

by hansichen

Good work, I really like these screwheads compared to the ones in the last build.

Posted: 27 Mar 2018, 15:18

by PlastikSchnittstelle

I like both screw types. letting people choose which they want would be a logistic nightmare for me. so I consider just giving everyone a set of both types. then you can decide when you get them.

Posted: 27 Mar 2018, 15:40

by faxe

I like your pragmatic approach

Posted: 27 Mar 2018, 16:21

by Anakey

Although i missed the IC forms etc i am really liking the looks of the case and trying to be something different that isn't just lets mill this block of aluminium into a shape. I already have a project to do over the summer but i might pick this up for later.

Posted: 27 Mar 2018, 16:49

by thokir

PlastikSchnittstelle wrote: ↑I like both screw types. letting people choose which they want would be a logistic nightmare for me. so I consider just giving everyone a set of both types. then you can decide when you get them.

Please do so... I hate those 'Linsenkopfschrauben' so much, it'd be a nightmare for me to build it with them. And getting the other screws in black won't be that easy, too, I guess

Posted: 27 Mar 2018, 19:02

by Menuhin

PlastikSchnittstelle wrote: ↑Yesterday I made a second build from the samples I got. This time the HHKB version. Wanted this to be a perfect build so it took quite some time,

here is the IMGUR album.

Here a little teaser:

SKB60-sample-HHKB (00).jpg

After I finished the build late at night yesterday, I noticed

wodan had put up a stream. I found this to be quite ironic. While he was having fun with his new hightech soldering iron, I was desoldering and soldering with cheap amazon stuff

Wodan always makes things look so easy and fun in his sub 60 or sub 90 minutes live streams.

When I was having hours and hours or even days of frustrations, doing the same or very similar tasks.

By the way, what lube did you use and where did you get them from?

Posted: 28 Mar 2018, 05:20

by kokokoy

Looks great man. Btw, did you do a 75% sample?

Posted: 28 Mar 2018, 15:37

by PlastikSchnittstelle

RealLaugh wrote: ↑Looks so good, can't wait for the GB and can't decide if standard 60% or WKL...but anyway great job on the Proto it looks great! Would be interested to get an idea of weight on your finished build and also maybe get a typing test to hear how it sounds.

yes, a typing test, sure, that would be great. I just don't have the right equipment to do that. would an iphone 6s be ok? don't mobile phones have automatic noise cancellation? if so it would not produce an accurate representation of the sound, right? not sure how to takle this without spending a lot of money.

Posted: 28 Mar 2018, 15:38

by PlastikSchnittstelle

no, sorry, they won't work. we settled on the screw type some time ago.

Posted: 28 Mar 2018, 15:52

by PlastikSchnittstelle

kokokoy wrote: ↑Looks great man. Btw, did you do a 75% sample?

as much as i would have liked to, this would have been too expansive.

I got five pieces of the same parts as sample:

5x plate-a

5x bottom

5x top (though top parts are 3x standard and 2x hhkb)

It is basically the same price if i do just one case or five. setting up the machines is what costs so much. adding different parts would require a different machine setup again. more of the same part instead doesn't require any new setup.

Posted: 28 Mar 2018, 16:04

by PlastikSchnittstelle

Menuhin wrote: ↑

By the way, what lube did you use and where did you get them from?

for the stabs i used

OKS 1110 Silikonfett. for the switches, after researching for a long time, I decided to use

Reely Silikon-Stoßdämpfer-Öl. you can get it in in many different levels of viscosity - i went for 800. I used it already for the 65% prototype build which has gateron black switches. I use the prototype board since last summer and I think the result was and still is perfect.

this method saved me a lot of time.

Posted: 28 Mar 2018, 19:47

by Menuhin

PlastikSchnittstelle wrote: ↑Menuhin wrote: ↑

By the way, what lube did you use and where did you get them from?

for the stabs i used

OKS 1110 Silikonfett. for the switches, after researching for a long time, I decided to use

Reely Silikon-Stoßdämpfer-Öl. you can get it in in many different levels of viscosity - i went for 800. I used it already for the 65% prototype build which has gateron black switches. I use the prototype board since last summer and I think the result was and still is perfect.

this method saved me a lot of time.

Recipe straight from the locals, I appreciate it!