Page 2 of 6

Posted: 07 Nov 2017, 11:44

by TapX

Filled out the form. The whole angle adjustment idea sold me on this one. I'd be down for a winkeyless full height version.

Posted: 07 Nov 2017, 12:26

by Shihatsu

Hold on, I got this - lmao

(yeah yeah, filled the form)

Posted: 08 Nov 2017, 14:01

by lordzebu

Looks interesting! Filled in the form.

Posted: 10 Nov 2017, 13:58

by PlastikSchnittstelle

@lordzebu:

great to have you back!

hope you'll soon find the time to reignite your mod-kit

---

## small updates

so far 91 have filled out the form. all 60 versions combined make up for more that 50% of the votes.

right now I'm trying to figure out between two different ways to go for:

a) only offer the case as standard 60% with universal plate

b) offer everyone can choose his favored 60% with custom plate

a) would dramatically lower the interest I guess and it wouldn't be very special. but we would know the pricing.

b) would be a very unique GB and everyone could get what he really desires instead of a vague compromise.

a mixed order would drive up the price quite a bit because I now have many different parts. but it may be the higher interest rate/overall production count would mitigate for this.

also b) would be impossible to name a price for. I would only know how much after I know exactly how many orders are safe. I could only estimate a price range and hope I'm not mistaken. buyers would have to agree to that. managing all the different orders would also be quite a challenge.

so I'm standing in front of a crossroad now, really difficult decision.

AND I'm feeling more and more tempted to go for steel. but that's another thing I have to discuss pros & cons about this with the manufacturer first.

Posted: 10 Nov 2017, 14:57

by TapX

Why not have a universal plate but different top parts with blockers? (like an HHKB top part, a WKL and a normal one). Wouldn't that be cheaper since you'd only have to produce one different part per set?

Posted: 10 Nov 2017, 15:11

by PlastikSchnittstelle

well, if i decide to go with the custom offer, then the different top parts are the most important. yes then it should be standard, hhkb, wkl and yas. but a unified plate for all of these would make a pretty bad plate I think. of course not everybody could get the exact plate he wishes but at least about 2-6 different version I guess would lead to plates with decent bottom row cutouts.

Posted: 17 Nov 2017, 10:36

by PlastikSchnittstelle

renderings of the new version (6degree and high-profile 2mm sink-in) for the different 60layouts are here. also new form. need your feedback. 75%-only is still not ruled out due to the feedback on GH.

Posted: 17 Nov 2017, 13:51

by pdc

I like the idea of a YAS62-style case but if I want to do a layout with my own special design of bottom row, or use ALPS switches, then I will want to make my own plate. Would it be easy to supply a specification for where the cutouts for the screws need to be to fit this case?

Posted: 18 Nov 2017, 19:17

by PlastikSchnittstelle

that would be no problem at all.

as soon as it is 100% sure that no more design changes will happen, i can send you (or just post for all) the CAD data for the plate.

Posted: 20 Nov 2017, 02:12

by ideus

This high profile case allows the use of a PCB mounted design. Personally I find the feeling and sound of a PCB mounted keyboard having a great tactility and it provides a less tiring typing surface. I really do not care about the plate, besides, a PCB mounted board facilitates changing the switch internals.

Posted: 20 Nov 2017, 17:03

by PlastikSchnittstelle

PCB mount?

maybe I'm missing something here, but I don't think PCB mount will be possible?

Posted: 20 Nov 2017, 17:07

by PlastikSchnittstelle

OK, after some consultation with the manufacturer I'm now planning to offer all 60% versions AS WELL AS 75%. I assume that the different versions won't cannibalize each other. Also, making a combined order is cheaper than making separate runs for 60% and 75% cases.

There are so many 75% PCBs available from china, but unlike 60% there are not a lot cases to choose from.

I'm considering sandblasting before anodizing to get a very high end. Depends on how much it would impact the final price and your feedback.

I'd hope to get some more opinions regarding countersunk vs flathead screws.

Next up I will do new renderings of the 75% version (probably next week).

Then I'll have to find out how much orders there will be. Only then I can name a reliable price.

Another (third) form will help to find that out. This form will probably also let you choose your preferred plate/layout. This still needs time since I haven't quite figured out jet how the balance between unified and specialized will look like. It will be a lot of work for me, I don't thinks GBs offer different plates/layouts to choose from most of the time.

Posted: 20 Nov 2017, 19:19

by faxe

75% woohoo! Keep up the great work!

Posted: 20 Nov 2017, 23:02

by ideus

The stand off are for the plate, so PCB mounted switches are not an option.

Posted: 21 Nov 2017, 11:16

by s3vv4

Sandblasting would fit the overall theme of the case perfectly I think.

Posted: 21 Nov 2017, 12:05

by FSund

75% is amazing!

Posted: 22 Nov 2017, 00:31

by ideus

The screw-affair could be easily settled by sharing some renders of the two options.

Posted: 22 Nov 2017, 15:57

by PlastikSchnittstelle

ideus wrote: ↑The screw-affair could be easily settled by sharing some renders of the two options.

ok, you mean countersunk vs flathead or how the screws fasten the plate?

I guess you mean the last one. sorry I wasn't really aware, that it is not clear. probably I take this for granted too much.

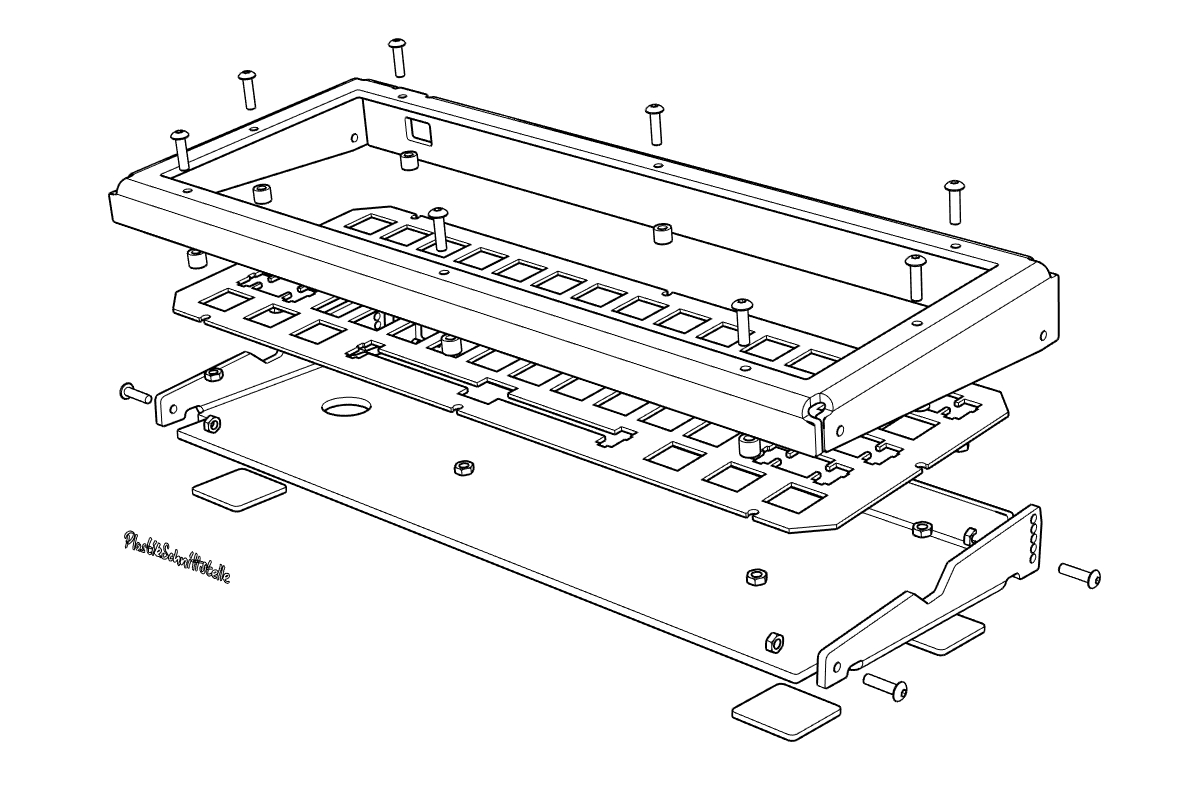

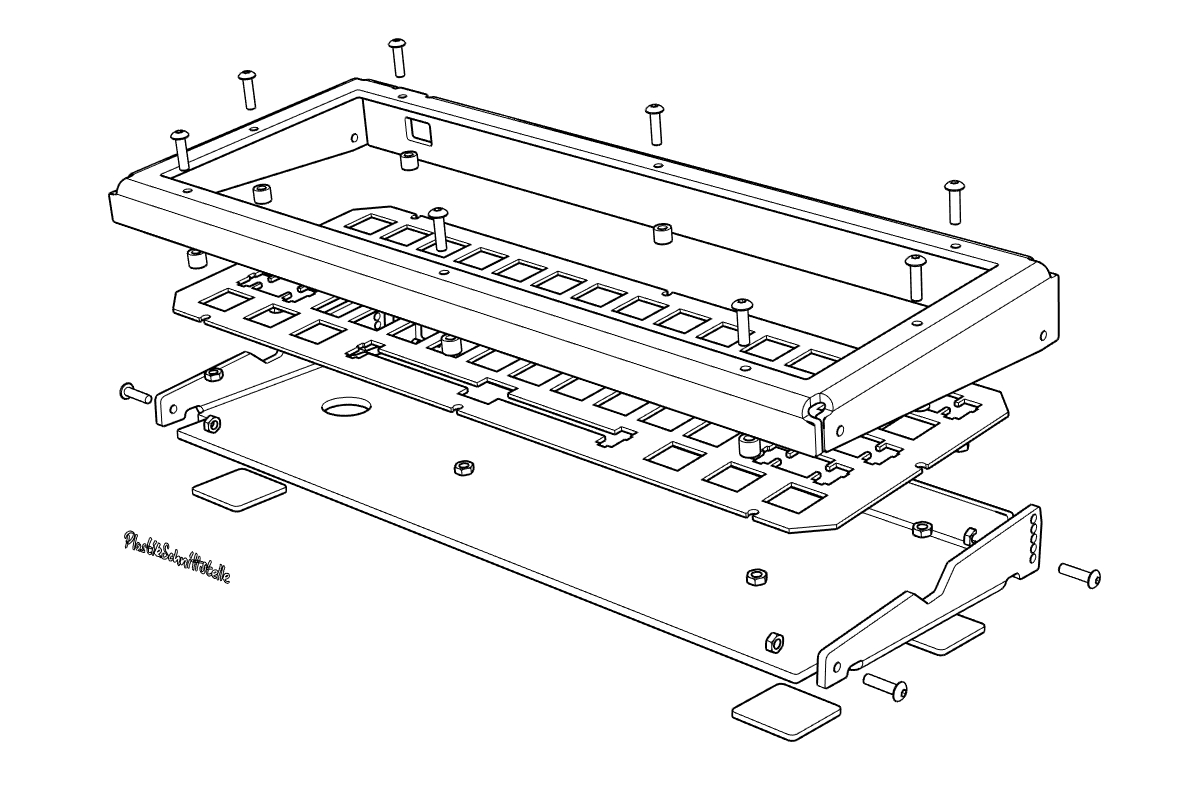

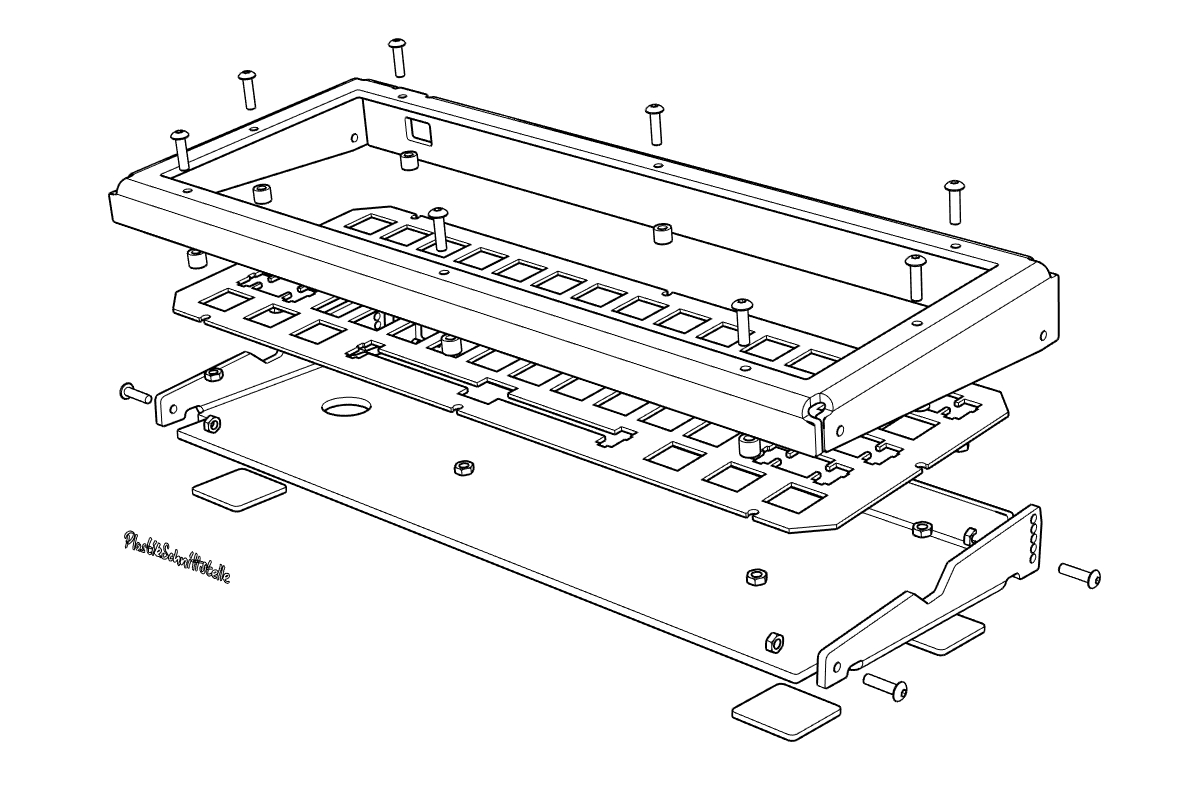

later this day I'll just share some screengrabs from the cad app here.

Posted: 22 Nov 2017, 16:34

by Wodan

PlastikSchnittstelle wrote: ↑PCB mount?

maybe I'm missing something here, but I don't think PCB mount will be possible?

Damn man you really know how to trigger me.

Very nice drawing, you're really gifted. Can't wait for this to proceed.

Posted: 22 Nov 2017, 18:26

by PlastikSchnittstelle

Thank you very much

But let me clarify something regarding the style of this drawing.

It is kind of a standard or at least very popular style used in product design (maybe in architecture as well). It is mostly used in earlier concept phase of the design process. a few years back the standard procedure was to export the model from CAD and into illustrator and there deal with the line weights. today that's easier, this is more or less just a screengrab directly from CAD using a slightly modified display mode.

so long story short: this is not a very special style I came up with, it's a pretty standard type of visualization used in product design.

Posted: 22 Nov 2017, 18:59

by PlastikSchnittstelle

Posted: 22 Nov 2017, 19:26

by pomk

That's a pretty clever design! Would like to see countersunk screws or some very low profile ones though (like these:

https://uk.misumi-ec.com/vona2/detail/110302280540/ ).

Posted: 22 Nov 2017, 19:31

by PlastikSchnittstelle

Haven't made a decision jet but probably going back to countersunk screws like seen in the initial renderings.

WAIT, those "ultra low head" screws look really interesting - thank you very much for that link.

seriously considering that.

Posted: 22 Nov 2017, 19:59

by PlastikSchnittstelle

After the new renderings of the 75% are done, I'll direct the discussion to the plate and layouts.

I will try to determine which layouts have the biggest common denominator - those will get their own, non-universal plate. less popular layout wishes will be condensed to a unified plate.

I think this way most of you will have the chance to get a perfectly fitting and uncompromising plate.

Posted: 22 Nov 2017, 20:04

by Shihatsu

Pleasepleaseplease have some ISO-love

Posted: 22 Nov 2017, 20:10

by PlastikSchnittstelle

Shihatsu wrote: ↑Pleasepleaseplease have some ISO-love

of course ansi AND iso.

you mean if they get their own plate versions? dedicated ansi and iso to avoid the big, weird cutout, that's what you mean?

probably, yes. quoting myself here:

PlastikSchnittstelle wrote: ↑After the new renderings of the 75% are done, I'll direct the discussion to the plate and layouts.

I will try to determine which layouts have the biggest common denominator - those will get their own, non-universal plate. less popular layout wishes will be condensed to a unified plate.

I think this way most of you will have the chance to get a perfectly fitting and uncompromising plate.

Posted: 22 Nov 2017, 20:41

by pomk

PlastikSchnittstelle wrote: ↑Haven't made a decision jet but probably going back to countersunk screws like seen in the initial renderings.

WAIT, those "ultra low head" screws look really interesting - thank you very much for that link.

seriously considering that.

Yeah, they have an amazing selection of hardware parts. The only possible downside is that they don’t deal with private customers for some reason.

Posted: 22 Nov 2017, 22:54

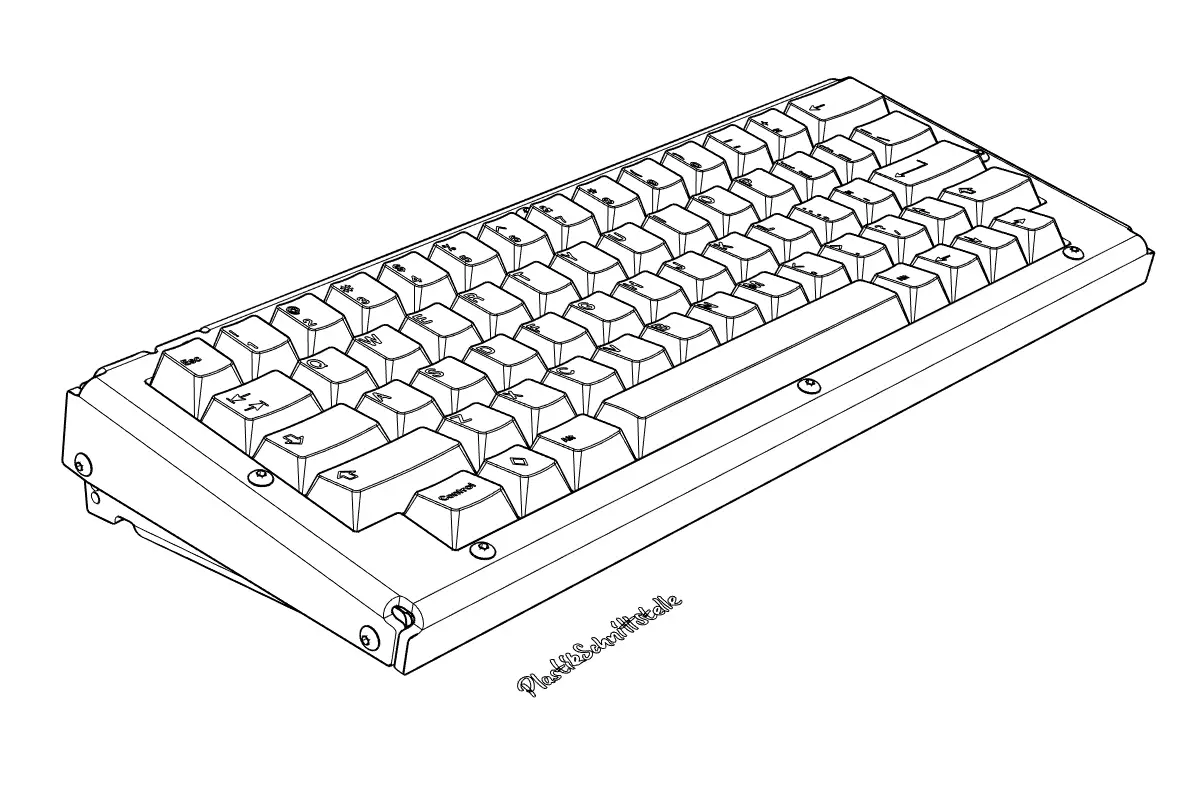

by PlastikSchnittstelle

since wodan likes the drawing style so much, here is one more:

- SKB60L-YAS.jpg (320.32 KiB) Viewed 14451 times

Posted: 22 Nov 2017, 22:59

by Myoth

PlastikSchnittstelle wrote: ↑since wodan likes the drawing style so much, here is one more:

SKB60L-YAS.jpg

Wodan won't like it ... it's not ISO !! HERESY !!

Posted: 22 Nov 2017, 23:30

by DarKou

Myoth wrote: ↑PlastikSchnittstelle wrote: ↑since wodan likes the drawing style so much, here is one more:

SKB60L-YAS.jpg

Wodan won't like it ... it's not ISO !! HERESY !!

The only one true layout: HHKB!