Condolences. Don't know what else to say. Been there.

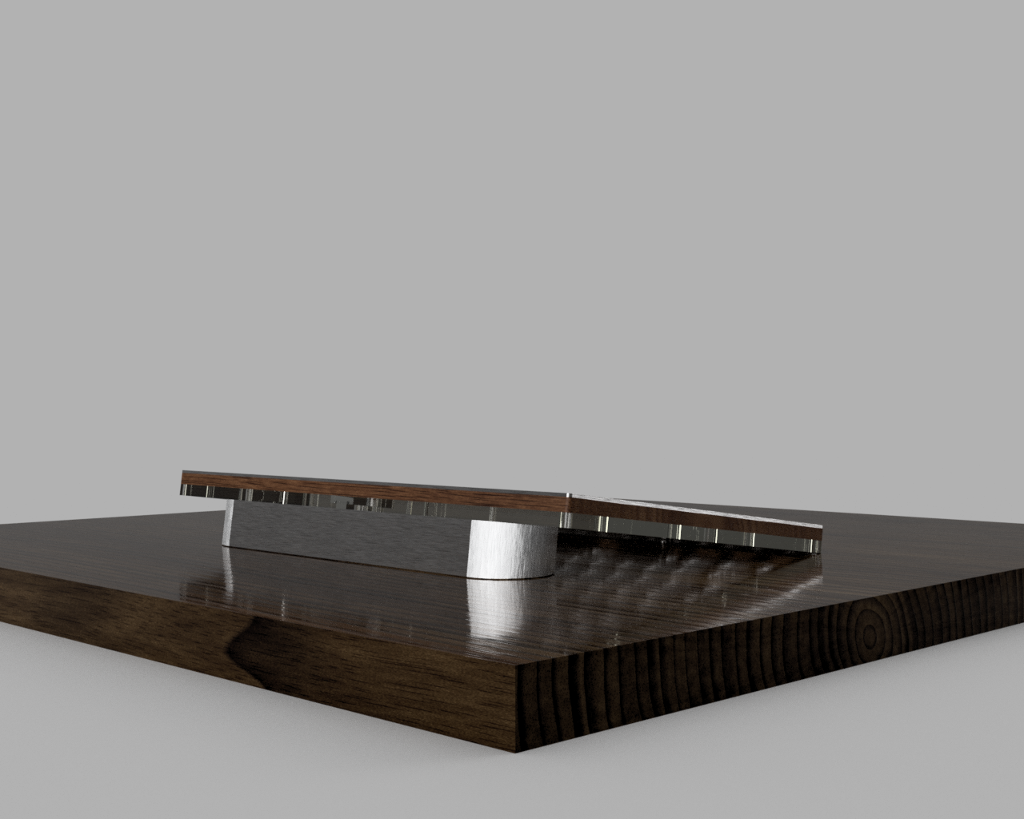

Hey, that's Apple BT keyboard on the attachment! BS will be much higher.

Compressing PCB on the sides will require something

pervertedinventive - like branching out the sense part to the coprocessor to which the main part of the controller will talk via some serial bus and putting that somewhere between enter and del key.

Which kind of rules out HHKB-style layouts - because it has to be on the top side of the PCB (don't think one can drive 'em from the top, though this worth testing), must have enough space for the sense traces and bypass capacitor(s) around it.

Link to the main controller and power can be brought from the lower layer - but that would mean vias. Don't know squat about PCB production, but it seem to make PCB more complex, hence more expensive.

BT would make lots of sense for this one - it will probably weigh less than 4 pounds. But the power drain of this two-chip system will mean battery life of like 5 minutes

Although it needs to have some sort of leg along the back of it to provide some incline. This can be used for batteries.

Update: BUT!

Using interlaced scan it may just be possible to bring the sense lines to the controller using the other side of the board - i.e. vias. Signal will probably be quite weak because TONS of parasitic capacitance, I'm afraid.

But. It is a Worthy Challenge.

For phase 2.

Hey, any actual electronic engineers around there? Or at least people knowing a way around PSPICE?

I can write firmware (it seems), but if I'll be designing this I'll spend all my breakfast money on the 50 PCB prototypes it will take me to approach something remotely reproducible. Etching the first 40 at home will probably be a bit cheaper (single key prototypes are out of the question, so lots of laminate), but my rental apartment manager will go nuts if he finds out I have copper salts, hydrochloric acid, peroxide _and_ a small child in close proximity of each other on his property.