I went ahead about put together the vertical stabilizers that were mentioned in the original reply to this. The dimensions will be adjusted when I return from my work trip and can look at the 1390653, but it should be very close. We would likely just make these be part of the base FEXT "base kit" like the spacebar stabilizer barrels so that it would let folks move the assembly from board to board without needing to change any barrel configurations (a little extra cost over the standard barrel, but a minimal trade-off for uniformity and later flexbility). The other option would be to have the standard F hybrid barrel cutout there as well, but then you would want to create some plug/cap to keep debris from getting to the PCB. Again... nice catch emdude Additional renderemdude wrote: ↑The thought did not occur to me until now, but I think you will need additional stabilizer cutouts for the '+' and the 'Enter' keys on the numpad to support the early Model Ms (1390131s, 1390120s, and early 1391401s) which used wire stabilizers for those keys.

(Model MF) Remodeling the Model M (aka.. the Mara)

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Spoiler:

Spoiler:

Last edited by lot_lizard on 02 Jun 2016, 21:34, edited 1 time in total.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

I am getting nervous with the proliferation of additional keypads in the lower row.Phenix wrote: ↑Will you also add the oppurtunity for split spacebar cutouts?

IIRC it was discussed earlier.

It was already complex to add the XMIT keys.

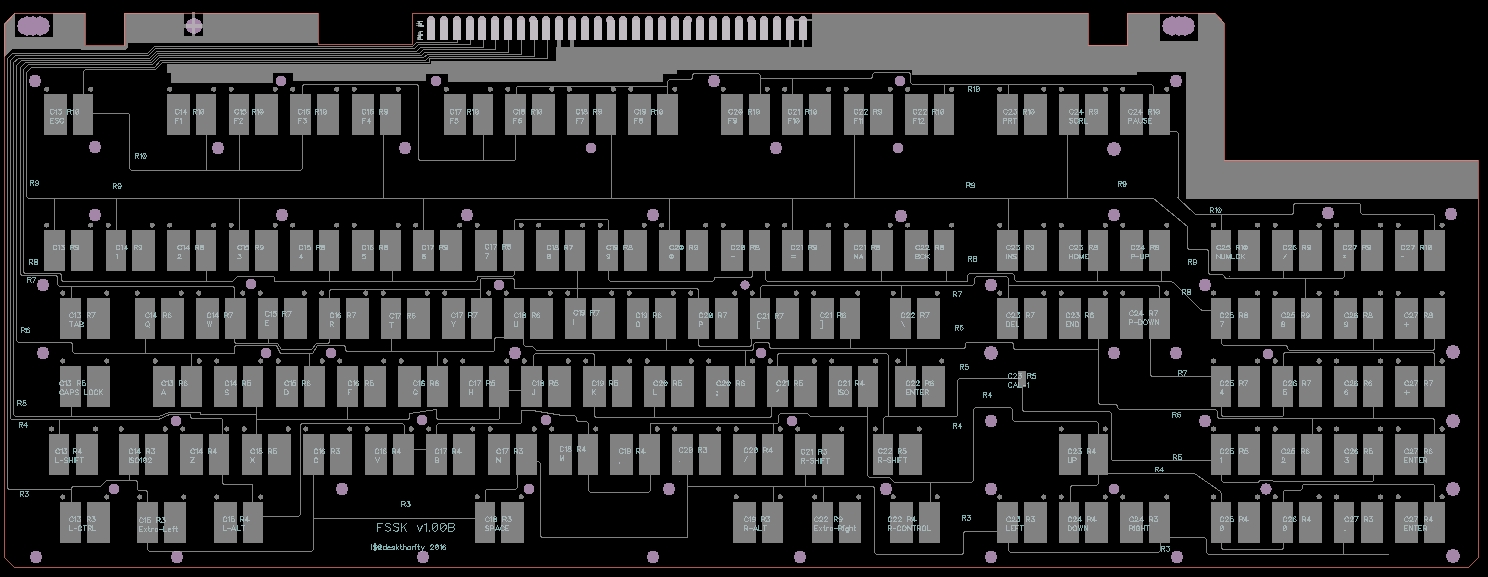

Reference to the FEXT v1.0b design here -> post298412.html#p298412

We need to check how to add the space-bar split and the new key in the left block ... I cannot confirm that it will be possible without deep analysis + deeper re-engineering.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

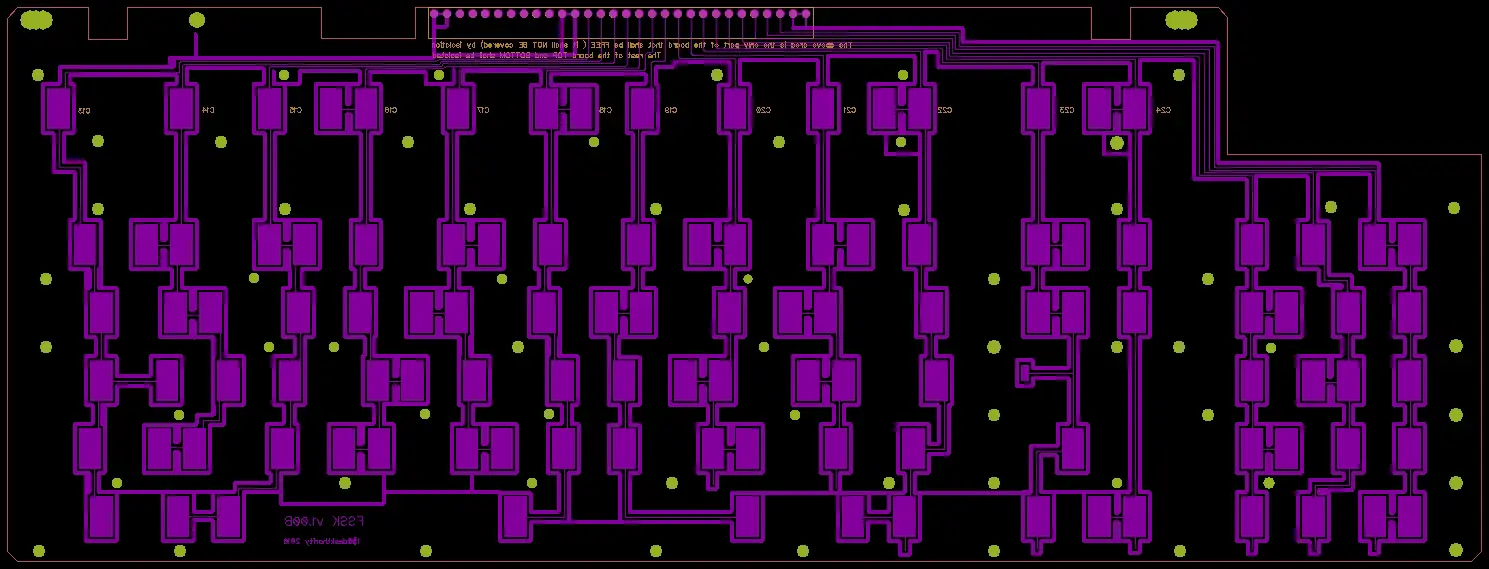

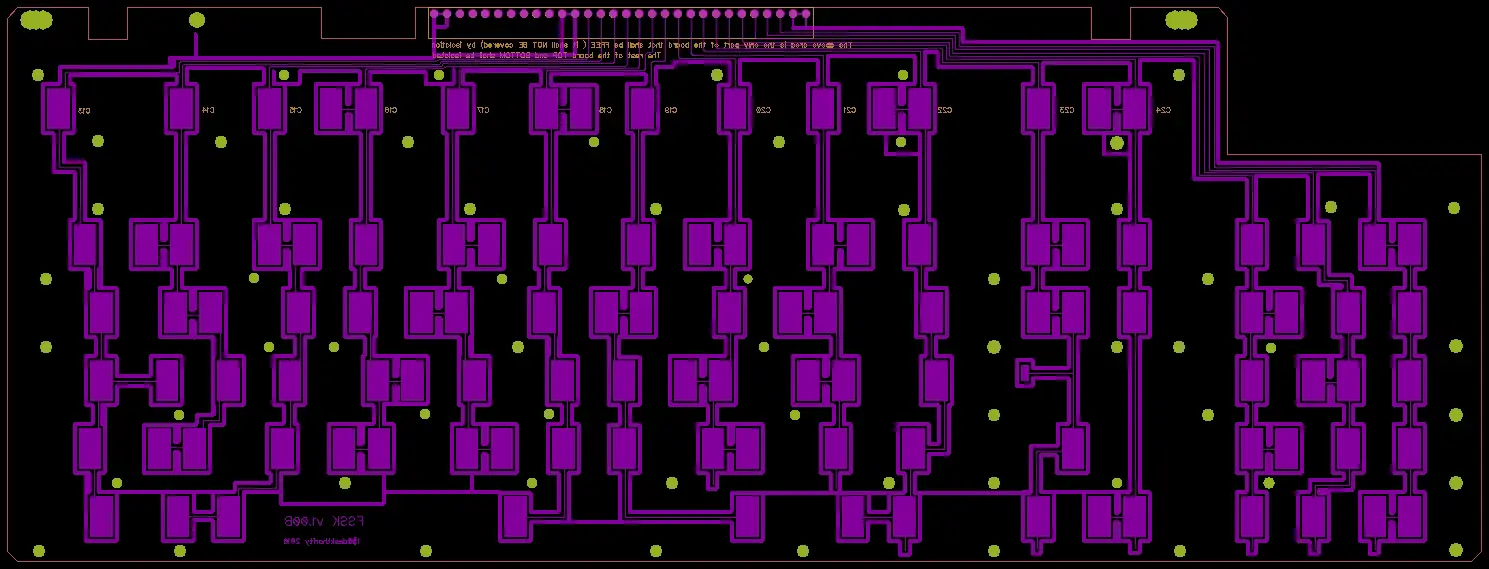

-- The maximum number of keys per column is 8.

An initial look at the FEXT v1.0b matrix leaves no space for the extra key in the left (red bubble)

The broken-spacebar may be done (green bubble)

There is no need to say that one could redesign the complete PCB as all the source files are available.

I will not have the time required to do it.

An initial look at the FEXT v1.0b matrix leaves no space for the extra key in the left (red bubble)

The broken-spacebar may be done (green bubble)

There is no need to say that one could redesign the complete PCB as all the source files are available.

I will not have the time required to do it.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Aw, booger.

Anyway, I wasn't planning to make use of those extra keys myself. But it's definitely a nice thing to have in the PCB, for future use.

Oh, does this apply to the SSK as well? I'm just assuming so. That's the only one I'm interested in.

Anyway, I wasn't planning to make use of those extra keys myself. But it's definitely a nice thing to have in the PCB, for future use.

Oh, does this apply to the SSK as well? I'm just assuming so. That's the only one I'm interested in.

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

This is awesome, you guys! I'm loving that 103 layout. It'll be absolutely perfect for a full size model F with the optimal layout.

Idollar, you'd brought up the idea of having the controller integrated into the PCB in the future. Is that something you plan to work on eventually? It seems prudent to see how the new capsense controller project comes along first, though. The per-key detection thresholds they are talking about might help to future proof the design. It could be especially helpful if someone needs to use a mix of old and new flippers together.

Idollar, you'd brought up the idea of having the controller integrated into the PCB in the future. Is that something you plan to work on eventually? It seems prudent to see how the new capsense controller project comes along first, though. The per-key detection thresholds they are talking about might help to future proof the design. It could be especially helpful if someone needs to use a mix of old and new flippers together.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

It needs to be done in steps, but yes, we could integrate the it. I need to find time to do it, as alwaysTechno Trousers wrote: ↑ Idollar, you'd brought up the idea of having the controller integrated into the PCB in the future. Is that something you plan to work on eventually? It seems prudent to see how the new capsense controller project comes along first, though. The per-key detection thresholds they are talking about might help to future proof the design. It could be especially helpful if someone needs to use a mix of old and new flippers together.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

Look at this, it may resolve the issue.Muirium wrote: ↑Aw, booger.

Anyway, I wasn't planning to make use of those extra keys myself. But it's definitely a nice thing to have in the PCB, for future use.

Oh, does this apply to the SSK as well? I'm just assuming so. That's the only one I'm interested in.

Step 1) - The real problem is that the entry left in the column 13 (first column) is the row 8, which is at the top.

This means that we have to find a way to route differently all the top layer at least for this first column. The good news is that this is a column at the edge of the PCB, which means that there is more freedom in the redesign

Step 2) The step 1 will free the row 3 in the column 16, which could be used for the extra key on the left.

Step 3) The column 18 is having 7 entries only, so we could check if there is room for a different pad for a broken bar.

As you can see, the problem is not trivial.

We will need to prototype again to make sure that these changes work, and I do not have a mounting kit for all these extra keys.

- idollar

- i$

- Location: Germany (Frankfurt area)

- Main keyboard: IBM F or M

- Favorite switch: BS

- DT Pro Member: -

The FSSK is a reduced version of the FEXT. The files that I have posted are having many layers. Combining them it should be possible to create FSSK or FEXT gerber files.Muirium wrote: ↑ Oh, does this apply to the SSK as well? I'm just assuming so. That's the only one I'm interested in.

So the answer to your question is : YES, it does apply to both.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

Understood.

I think it's a "nice to have" to have feature, but not essential. We're using original cases after all. It's easiest not to mod them. This can wait.

I think it's a "nice to have" to have feature, but not essential. We're using original cases after all. It's easiest not to mod them. This can wait.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Some updates... I received several packages this last week while out, and finally had the opportunity to unbox this morning

FEXT PCB

The most important... I received my FEXT PCB from i$ (number 4). It arrived well packaged, and in beautiful shape. Thanks again for all of your work. I can't wait to dive into it Also, I received my prints for the spacebar stabilizer barrels, the flipper, and the Cherry MX adapter mounts (standard key and spacebar). I am really pleased with the quality of the prints, with an exception of the stem portion for the Cherry spacebar adapter. It arrived warped (I have let Shapeways know, and they are sending a replacement). The action on all of these parts is very smooth (little if any difference from the standard stems and barrels). You will notice occasional artifacts hanging off the print edges in the pics, but this is just a part of the printing process that needs to be tidied up (not in the original designs, and wouldn't be present in molds).

Stabilizer Barrels (Spacebar)

I am finally getting to test the stabilizer barrel concept (barrel with integrated clip vs. independent clip on the top plate), and it is everything I hoped it would be. Barrel tolerance on the keystem is ideal, and the action of the spacebar stabilizer inside the clip is secure but glides freely. There will not need to be any additional adjustments made. Additional photos

Flipper

The angle and action of the flipper is nice and crisp, and I can not tell any discernible difference between the dimensions of the original and the reproduction. We won't actually know how effective it is until produced from a conductive plastic (still waiting on results from the lab for FTIR testing). Cherry MX keystem adapter (standard)

Finally getting to test the Cherry MX mount itself against a real physical SA key is a treat. The fit is secure, but easily able to be removed (leaving the keystem in the barrel). The action is now perfect (or I close as I can get it), and very smooth. I do have the opportunity to lower the key profile ~2mm into the stem further, and will take advantage of that (these SA caps sit up high). I think I will split the difference between the SA and DSA profiles (as compared to the IBM key profile) so that either could be used if desired. I will report back when the new print with profile changes comes in (assume 2+ weeks). Additional photo

Along with the prints, I received all the M2/M3 screw hardware from Fastenal. I am experimenting with several different screw lengths to find the best combination of lower profile while still making the assembly easy. The screws will be tapped into the top plate (countersunk in the bottom plate). This is different from the original plastic prints since there wasn't enough "meat" to support a screw tap.

The FEXT water-cut top plate is scheduled to deliver tomorrow (the bottom plate I have already made). I should have updates regarding both the FSSK and FEXT metal plate assemblies this week. Stay tuned...

FEXT PCB

The most important... I received my FEXT PCB from i$ (number 4). It arrived well packaged, and in beautiful shape. Thanks again for all of your work. I can't wait to dive into it Also, I received my prints for the spacebar stabilizer barrels, the flipper, and the Cherry MX adapter mounts (standard key and spacebar). I am really pleased with the quality of the prints, with an exception of the stem portion for the Cherry spacebar adapter. It arrived warped (I have let Shapeways know, and they are sending a replacement). The action on all of these parts is very smooth (little if any difference from the standard stems and barrels). You will notice occasional artifacts hanging off the print edges in the pics, but this is just a part of the printing process that needs to be tidied up (not in the original designs, and wouldn't be present in molds).

Stabilizer Barrels (Spacebar)

I am finally getting to test the stabilizer barrel concept (barrel with integrated clip vs. independent clip on the top plate), and it is everything I hoped it would be. Barrel tolerance on the keystem is ideal, and the action of the spacebar stabilizer inside the clip is secure but glides freely. There will not need to be any additional adjustments made. Additional photos

Spoiler:

The angle and action of the flipper is nice and crisp, and I can not tell any discernible difference between the dimensions of the original and the reproduction. We won't actually know how effective it is until produced from a conductive plastic (still waiting on results from the lab for FTIR testing). Cherry MX keystem adapter (standard)

Finally getting to test the Cherry MX mount itself against a real physical SA key is a treat. The fit is secure, but easily able to be removed (leaving the keystem in the barrel). The action is now perfect (or I close as I can get it), and very smooth. I do have the opportunity to lower the key profile ~2mm into the stem further, and will take advantage of that (these SA caps sit up high). I think I will split the difference between the SA and DSA profiles (as compared to the IBM key profile) so that either could be used if desired. I will report back when the new print with profile changes comes in (assume 2+ weeks). Additional photo

Spoiler:

The FEXT water-cut top plate is scheduled to deliver tomorrow (the bottom plate I have already made). I should have updates regarding both the FSSK and FEXT metal plate assemblies this week. Stay tuned...

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

That's impressive.

Some notes:

Layout-wise: why not make the matrix more than 16 columns wide? GPIO pins are cheap. 74AHC595 are also not that expensive. Different hardware will be required though - PCB et all.

But this will allow to make any layout possible - even with whole bottom row consisting of 1u keys

Logo-wise: Why not just make "HAL" logo in IBM font? As lot_lizard mentioned somewhere above, eventually there will be no IBM parts in it.

Some notes:

Layout-wise: why not make the matrix more than 16 columns wide? GPIO pins are cheap. 74AHC595 are also not that expensive. Different hardware will be required though - PCB et all.

But this will allow to make any layout possible - even with whole bottom row consisting of 1u keys

Logo-wise: Why not just make "HAL" logo in IBM font? As lot_lizard mentioned somewhere above, eventually there will be no IBM parts in it.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

I think you are summing phase 2 of this nicely. Once we get this drop-in replacement turned into reality (I think we are weeks away from everything not Cherry related being released), hardened, and all iCap released to the planet. To rephrase, let the group buy research really commence. Unless some unforeseen mistakes have been made, and then a few additional weeks to correct. We have M's in spades waiting for this, and it can happen in the foreseeable.DMA wrote: ↑That's impressive.

Some notes:

Layout-wise: why not make the matrix more than 16 columns wide? GPIO pins are cheap. 74AHC595 are also not that expensive. Different hardware will be required though - PCB et all.

But this will allow to make any layout possible - even with whole bottom row consisting of 1u keys

Logo-wise: Why not just make "HAL" logo in IBM font? As lot_lizard mentioned somewhere above, eventually there will be no IBM parts in it.

Then we turn this project on it's head (or at least try to). ADC the controller, compress the PCB (with extra keys), make the assembly plates flat (it works... haters move along

Step 1... Drop-in F assembly for M's. The ADC controller you are concocting is a huge part of step 2 if you are game. Baby steps though to prove viability. The M update to provide F switch capability is massive imo. It lets people take advantage of something beautiful right away, and then several of us play mad scientist in a coordinated effort

- pyrelink

- Location: USA

- Main keyboard: HHKB 2

- Main mouse: CST L-Trac

- Favorite switch: Capacitive Buckling Spring

- DT Pro Member: -

Again I am blown away lot_lizard. The in-barrel stabilizer design looks great, and is super impressive to me that its working that well on the first try. Can't wait for your next updates. Really excited to find out the true makeup of Model F flippers!

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

Controlling the scope is of utmost importance, I agree.lot_lizard wrote: ↑Step 1... Drop-in F assembly for M's. The ADC controller you are concocting is a huge part of step 2 if you are game. Baby steps though to prove viability. The M update to provide F switch capability is massive imo. It lets people take advantage of something beautiful right away, and then several of us play mad scientist in a coordinated effort

I am game.

Need to get firmware to the state where it can be tested using the prototype kits first. Then to actual hardware design - I for some reason don't think cypress will sell even 150 of those (though if they will - it will probably be the most cost-effective controller option).

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Thanks guys... I agree... This is exciting. And we should never lose sight that I$'s experimentation with F flippers in an M barrel frame kicked this all off (continually deserves praise... Alongside Wcass's Xtant)

I verified, and we can drop the profile of the Cherry stem 2.6mm (massive). The reprints have been ordered, but I am very confident in the results ahead of time.

I do have bad news though... I can make EVERY KEY in a 101/103 key configuration work for the Cherry mount except the Capslock. We would have an easier job building a time machine than getting that one efin key to defy physics.

So... The Cherry adapters will wait until phase 2 (making our own layouts and cases). Sorry guys. But if we can't get 100% of the keys working, it's not worth doing for phase 1 (the M drop-in). We WILL make it easily work for step 2 (plus we can rearrange the PCB to reduce the number of adapters needed by increasing the number of times each special adapter can be used... Thus reducing cost). In the end... Goodness

I verified, and we can drop the profile of the Cherry stem 2.6mm (massive). The reprints have been ordered, but I am very confident in the results ahead of time.

I do have bad news though... I can make EVERY KEY in a 101/103 key configuration work for the Cherry mount except the Capslock. We would have an easier job building a time machine than getting that one efin key to defy physics.

So... The Cherry adapters will wait until phase 2 (making our own layouts and cases). Sorry guys. But if we can't get 100% of the keys working, it's not worth doing for phase 1 (the M drop-in). We WILL make it easily work for step 2 (plus we can rearrange the PCB to reduce the number of adapters needed by increasing the number of times each special adapter can be used... Thus reducing cost). In the end... Goodness

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

Why is it so? Is it because of the asymmetric mount and the forces trying to, erhm, rotate the keycap out of the stem? Or some other thing?lot_lizard wrote: ↑I can make EVERY KEY in a 101/103 key configuration work for the Cherry mount except the Capslock. We would have an easier job building a time machine than getting that one efin key to defy physics.

- DMA

- Location: Seattle, US

- Main keyboard: T420

- Main mouse: Trackpoint

- Favorite switch: beamspring

- DT Pro Member: NaN

- Contact:

Alsoo... Is this a model M flipper?

I'm looking now at model F one - it's definitely squarer, noticeably thinner at the end (did they try to save mass?) and has small "legs" at the bottom. You promised a post with comparisons of sounds of different combinations of flippers, barrels and how they're mounted. Are my search skills so bad I can't find it?

I'm looking now at model F one - it's definitely squarer, noticeably thinner at the end (did they try to save mass?) and has small "legs" at the bottom. You promised a post with comparisons of sounds of different combinations of flippers, barrels and how they're mounted. Are my search skills so bad I can't find it?

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Caps lock is a 1.75 with a single barrel (no stabilizer) and the barrel is offset in a way that one of the Cherry stems in the cap would have to be ground out to not collide with the existing M/F barrel on downward travel. If people didn't mind altering the Cherry cap, it is very doable, but was attempting to avoid that (and managed to come up with something that did for all others).DMA wrote: ↑Why is it so? Is it because of the asymmetric mount and the forces trying to, erhm, rotate the keycap out of the stem? Or some other thing?lot_lizard wrote: ↑I can make EVERY KEY in a 101/103 key configuration work for the Cherry mount except the Capslock. We would have an easier job building a time machine than getting that one efin key to defy physics.

If we coordinate moving the Capslock barrel on the PCB and top frame going forward, we can very easily make all Cherry adapters work (flat or curved plane). But if we are going to do that, we can also adjust the mounts for the other special keys and reduce the number of unique adapter mounts required. Right now we would be at 6 (not counting Capslock). Future layout could get that number down to 2 total (universal stem and spacebar), but existing IBM caps would no longer work on the future board. To me, that is no big deal since we would want Cherry caps anyway for custom layouts (custom legends on dye-sub PBT is basically off the table because of the lack of flexible suppliers).

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

There are basically two distinct barrel profiles, and three distinct flippers for the F

workshop-f7/model-f-flippers-t9715.html

I have opened up boards that have literally had all three flippers (assuming a repair?!?), but typically a given barrel and flipper are tied to a specific model. In every case, these are capacitive, and make contact with the PCB pad to conduct. The M flipper that emdude posted is a completely different animal. They are membrane boards, and the flipper works by applying pressure on the two membrane sheets (separated by a spacer sheet with cutouts) using an extrusion almost directly below the spring itself (why they call it a "pivot plate" vs flipper). The extrusion is hard to make out here, but it's the "bump"

I chose the XT style barrel since there is an advantage to having the "lock" further away from the barrel to prevent torsion. This is really only an issue with keys that would be isolated (ctrl, alt, spacebar, escape, etc), otherwise the barrels help hold each other in alignment.

The flipper... I just picked one. I could certainly be talked into another design if someone had an opinion. I will post that comparison breakdown today (be prepared... it's a long read), but in it I tried all three F flippers, and couldn't discern any audible or tactile differences. In each case, the spring is always identical

-

andrewjoy

- Location: UK

- Main keyboard: Filco ZERO green alps, Model F 122 Terminal

- Main mouse: Ducky Secret / Roller Mouse Pro 1

- Favorite switch: MX Mount Topre / Model F Buckling

- DT Pro Member: 0167

Thats some impressive work, a drop in assembly for a model M case is getting closer to a reality.

Just so i get this right , i could buy a case only from unicomp and drop the F assembly into it ?

Just so i get this right , i could buy a case only from unicomp and drop the F assembly into it ?

- fohat

- Elder Messenger

- Location: Knoxville, Tennessee, USA

- Main keyboard: Model F 122-key terminal

- Main mouse: Microsoft Optical Mouse

- Favorite switch: Model F Buckling Spring

- DT Pro Member: 0158

This is magnificent! Even if I don't do the entire project, I want half a dozen of these barrels. I would Dremel out slots in the top plate to use them as replacement barrels in original Fs.lot_lizard wrote: ↑

Stabilizer Barrels (Spacebar)

I am finally getting to test the stabilizer barrel concept (barrel with integrated clip vs. independent clip on the top plate), and it is everything I hoped it would be. Barrel tolerance on the keystem is ideal, and the action of the spacebar stabilizer inside the clip is secure but glides freely. There will not need to be any additional adjustments made.

- alh84001

- v.001

- Location: EU-HR-ZG

- Main keyboard: unsaver

- Main mouse: logitech m305 / apple trackpad

- Favorite switch: BS

- DT Pro Member: -

Backwards compatibility comes to mind. Xwhatsit's controller (and it's proposed derivatives) only has 16 column pins. While we're on the subject of controllers, theoretically speaking, do you think an original F controller would work with new custom assemblies? I know that sensing voltage can't be adjusted there, but I don't know what their tolerance is, or if they have some kind of auto-calibration built in.DMA wrote: ↑ Layout-wise: why not make the matrix more than 16 columns wide? GPIO pins are cheap. 74AHC595 are also not that expensive. Different hardware will be required though - PCB et all.

-

andrewjoy

- Location: UK

- Main keyboard: Filco ZERO green alps, Model F 122 Terminal

- Main mouse: Ducky Secret / Roller Mouse Pro 1

- Favorite switch: MX Mount Topre / Model F Buckling

- DT Pro Member: 0167

As far as i know the original F controllers ( and beamspring too i think) do have some limited auto calibration.

As for the rest of your points i do not know.

Support for Xwhatsit's is important ! A new controller may be a good idea in the long run , but why re-invent the wheel when we have something that works now ?

As for the rest of your points i do not know.

Support for Xwhatsit's is important ! A new controller may be a good idea in the long run , but why re-invent the wheel when we have something that works now ?

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Right... The goal of phase 1 would be to only use the Model M shell (and keys). I am not sure if Unicomp still has SSK cases, but the same would apply there as well.andrewjoy wrote: ↑Just so i get this right , i could buy a case only from unicomp and drop the F assembly into it ?

That's clever. Hadn't thought of that, but zero reason it wouldn't work well.fohat wrote: ↑Even if I don't do the entire project, I want half a dozen of these barrels. I would Dremel out slots in the top plate to use them as replacement barrels in original Fs.

You bring up interesting points alh84001. Someone with a stronger EE knowledge than me about these boards would have to chime in. As much tuning to the voltage as the xWhatsit takes, you would certainly assume the stock F controllers are auto-calibrating somehow. The issue would be the lack of USB. But if you are comfortable with XT, you could certainly save money on a controller if we did phase 1 "a la carte" (assuming there is room in the shell)alh84001 wrote: ↑Backwards compatibility comes to mind. Xwhatsit's controller (and it's proposed derivatives) only has 16 column pins. While we're on the subject of controllers, theoretically speaking, do you think an original F controller would work with new custom assemblies? I know that sensing voltage can't be adjusted there, but I don't know what their tolerance is, or if they have some kind of auto-calibration built in.

The ADC capsense would be for phase 2 (at the earliest). For phase 1 (the drop-in), we would be leveraging the xWhatsit for sure. There are too many new things going on to not take advantage of hardened components when possible (reduce the variables unless there is a immediate advantage). With the stock layouts, no reason to bring in something new unless there is a significant cost or performance benefit.andrewjoy wrote: ↑Support for Xwhatsit's is important ! A new controller may be a good idea in the long run , but why re-invent the wheel when we have something that works now ?

- elecplus

- Location: Kerrville, TX, USA

- DT Pro Member: 0082

- Contact:

So, are you guys possibly wanting Model M cases? I have some 122 keys that I have used the caps, so all that is left is the case and the "guts".

- elecplus

- Location: Kerrville, TX, USA

- DT Pro Member: 0082

- Contact:

Not really, because they only have one row of F keys on the top, and they have the numpad. The Unsavers have 2 rows F keys and no numpad. Unless you plan heavy modifications?