DMA wrote: ↑21 Apr 2023, 03:02

Just make those pads ESSK-style, and you'll probably get a decent enough boost (it's not multilayer, btw - it's single-sided essentially, the back side is basically solid ground).

Ahh apologies, I thought it would be multilayer, since I remembered you mentioned you had a ground layer, but then it must mean that you have small holes in the ground layer where the columns and rows pass over each other, right?

DMA wrote: ↑21 Apr 2023, 03:02

Also nothing prevents you from making all sense pads same smaller size and limit the signal range by pad, not flipper, to achieve a level field.

I'm not sure I understand. I would make the pads smaller to make it easier to route, but not sure why that would help with signal to noise ratio.

DMA wrote: ↑21 Apr 2023, 03:02

However, due to xwhatsit's "virtual ground" and generally ringy nature you'll likely drown in noise, because actual contact area will be ~1mm high.

I haven't seen much noise in xwhatsit, as long as key presses don't change, and as long as there's no heavy machinery operating above the keyboard. What I did notice is that without 'debouncing' (a lot of debouncing algos also do denoising), during the actuation of a key sometimes other keys can trigger on the same row. It only seems to happen very rarely probably when actuation coincides with the scanning pulse. I don't really have a good explanation for it. I can already filter most of this stuff out, by checking that the key is not already high before triggering the column, but some still happens when the actuation happens to fit between the column trigger, and the sample point.

But while no keys are actuating, and all keys are either unpressed, or being held down constantly, noise is very minimal, like +-2 LSBs of the 12-bit DAC. So just to put that into context, on my FAT, an example key has the signal level of 480 unpressed, 812 pressed, with the row sitting at 418 when no columns are triggering (this is with a 12-bit DAC). That +-2 LSB of noise is nothing. The noise that is actually caused by another key being actuated, I call it interference in my firmware. That is indeed a problem, cause it means I cannot use eager debouncing algorithms because of it, and puts a limit on achievable latency.

DMA wrote: ↑21 Apr 2023, 03:02

my experience shows that even a small dust particle getting under the flipper drops the key output to virtually zero, so a tiniest gap would suffice

Yeah, noticed that, I found it especially problematic with beamsprings though. Dust tends to not affect the unpressed state of Model Fs that much, and makes it easier to use unpressed signal levels as a calibration reference. With beamsprings it's more of a problem.

DMA wrote: ↑21 Apr 2023, 03:02

I wouldn't be gluing any copper tape anywhere if I were you - it's quite thick and so it's pretty hard to tell what will happen in advance, but likely nothing good.

I did some experiments with that and it seemed to work, as long as the copper tape was on the bottom. This was with single sided adhesive copper tape. No idea how long it would last. In any case I wouldn't sacrifice 101 Model F flippers for such an experiment. (converting an M2)

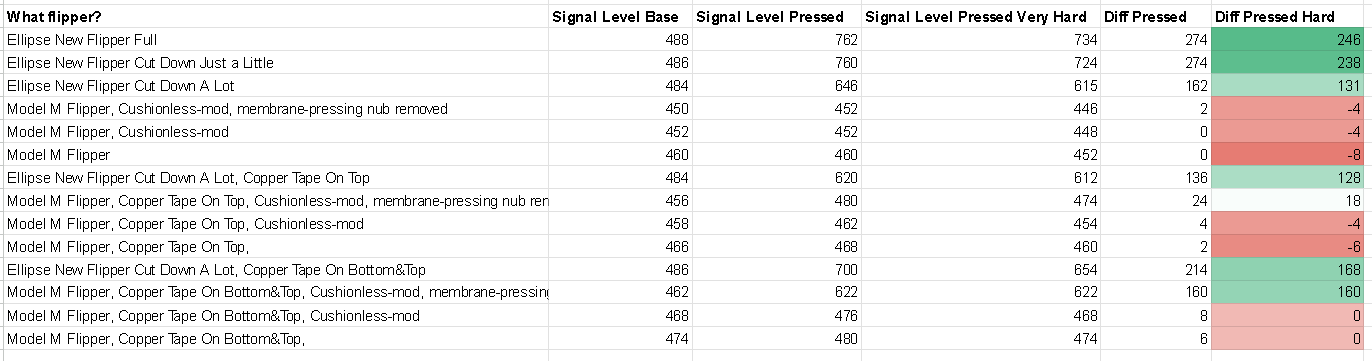

See my results, the small flippers were about half the signal level of a normal flipper, copper tape was a little better than conductive plastic. The "Cut down a lot" flipper is the M-sized F flipper from my video:

- levels.png (16.34 KiB) Viewed 2019 times

DMA wrote: ↑21 Apr 2023, 03:02

I found way back that printer paper thoroughly blackened with pure graphite (8B pencil works too) is quite detectable by CS (black side down), so may be if you do the same to the M flipper with some convincing of the graphite to stay there (with some ironing to fuse the graphite into the surface of the filpper, maybe?) it might just work.

I haven't really tried conductive sprays yet for this purpose, but an interesting idea to test. I tried spraying graphite spray on PCBs for another purpose, but it was always easy to remove it afterwards with just some alcohol. But maybe the solvent in the spray can melt the flipper a little and actually embed the graphite in it.

DMA wrote: ↑21 Apr 2023, 03:02

GH were not always registering, IIRC - It was like five years ago, hard to remember.. I reused it's backplate and case for taylorswift's FSSK plate, so it wasn't a total waste after all. I just have a pile of flippers I don't need.

Not sure if you're aware, but Unicomps and 4th gen Model Ms have this area where they pass signals from top to bottom layer:

https://imgur.com/a/zSxNAkH . If a single rivet is missing or loose in the top right of the keyboard, it can cause weird behavior, like keys sometimes working and sometimes not, and especially likely to be the cause if multiple keys are doing it at the same time. Doing a partial bolt mod often fixes it:

https://imgur.com/a/pzIFggD But sometimes you have to also add some pieces of paper under the bottom layer to increase the pressure there. In my experience the partial bolt mod was the most important. Dust in that area could also potentially be a problem. One way to test for this problem, is to remove the top right keycap, and press down on the top right barrel, if that pressure temporarily fixes problems, then you found the culprit. I think this is a very under-diagnosed problem, and since I've been spreading awareness of this possible failure mode, there were quite a few people who found out that this is exactly what was causing their issues. This won't help your Unicomp now, but I'm just taking every chance that I get to spread awareness of this, especially since it's fairly easy to fix, maybe more Unicomp keyboards will be fixed...