Page 2 of 7

Posted: 28 Jun 2013, 13:24

by Jmneuv

Are you considering stainless steel or regular one?

For screws you might find some with a nice flat 'lentil' head in the torx or hexagon range.

Posted: 28 Jun 2013, 13:27

by matt3o

Muirium wrote:Thanks Matteo. Those feet are pretty neat! And it looks to me like I could indeed put a nice shiny steel trim layer above the plate, around the outside edge of the solid rectangle of caps, and have a fine old reflective halo! One with screws in it, of course, but that's fine by me. What do you think?

with the current layout it wouldn't be possible I'm afraid. The top layer would hit the spacebar stabs, you would need to design the shiny top layer with a couple of dents to avoid the stabs.

A shiny/mirror plate would be fascinating though... as much as a brushed one actually

So many options

Jmneuv wrote:Are you considering stainless steel or regular one?

When I refer to steel, I always talk about stainless steel.

Jmneuv wrote:For screws you might find some with a nice flat 'lentil' head in the torx or hexagon range.

Can you find them in the M2.5 realm? Height 14-16mm

Posted: 28 Jun 2013, 14:59

by matt3o

small update on the stabilizers.

I didn't notice that there were some really small dents in the stabs holes, filed them away everything looks fantastic! So it seems I have the right specs for the stabs after all.

Posted: 28 Jun 2013, 15:05

by Muirium

matt3o wrote:with the current layout it wouldn't be possible I'm afraid. The top layer would hit the spacebar stabs, you would need to design the shiny top layer with a couple of dents to avoid the stabs.

A shiny/mirror plate would be fascinating though... as much as a brushed one actually

So many options

Exactly. Brownfox's aluminium plate is superior for typing, because of its gentle flex. But steel can shine! I'm trying to figure out how to get the best of both worlds.

How big would those space bar stab dents need to be? And could their inside surface still be reflective?

Posted: 28 Jun 2013, 15:12

by damorgue

Aluminum can have a nice finish too you know, you just have to seal it so that it doesn't oxidize.

Posted: 28 Jun 2013, 15:15

by Muirium

Absolutely. I love aluminium, and have it all over the place. It's the extra weight of stainless steel, and the available mirror finish from the supplier Matteo mentioned, that's attracting me to it. Or rather a bit of both.

Posted: 28 Jun 2013, 15:47

by matt3o

Muirium wrote:How big would those space bar stab dents need to be? And could their inside surface still be reflective?

just 1mm probably. the shiny part is just top and bottom (no sides). but you could have the case slightly bigger (1/2mm) and have a frame all around the keyboard.

damorgue wrote:Aluminum can have a nice finish too you know, you just have to seal it so that it doesn't oxidize.

it must be treated after the cut though (at least this is what they told me).

Posted: 28 Jun 2013, 16:02

by Muirium

This isn't something I know how to turn down!

The absurdly bling

Billings keyboard. A crazy cool keyboard for a bizarre machine.

The bottom of this thing looks better than most keyboards do on top.

Chrome plated steel. Polished stainless isn't quite as fancy-pants, but it's very almost as good. Come on Matteo, might a fox want a finish like this? At least on the base as a trial!

Posted: 28 Jun 2013, 16:09

by matt3o

that is going to get dirty as fast as saying "shiny"!

Posted: 28 Jun 2013, 16:13

by Muirium

Ah, that's what shirt sleeves are for. Polish polish polish…

Fortunately, I'm not thinking of quite that volume of extravagance. Just the edge, and the base!

Posted: 28 Jun 2013, 16:17

by matt3o

I must say it's sexy but I would stick on standard stainless steel, at least for the first batch, well... actually let's see how many orders we get. I don't think it will be a huge GB, I would be happy if we fill 1 alu sheet.

Posted: 28 Jun 2013, 16:23

by Muirium

Yup. So you definitely recommend aluminium for the plate layer of the keyboard cake? And steel for the base? Meanwhile the midsection is an acrylic / metal free for all.

I'm considering a shiny steel trim on top of the plate's outside edge specifically so I can retain the good characteristics of aluminium plate flex.

Posted: 28 Jun 2013, 16:32

by matt3o

I didn't think about it much but the idea is to have the following:

- 1.5mm Aluminum (mostly for plates)

- 1.5mm Stainless steel (mostly for the bottom but you can also have the plate if you want)

- 3.0mm Aluminum OR Stainless steel (for the sides if you don't want to go Acrylic)

I don't know if I should handle the acrylic layers as the company that cut the metals does not cut acrylic. Also services that offer acrylic laser cut are easy to find everywhere. Anyway if there's enough interest I could take care of that as well.

Posted: 28 Jun 2013, 17:34

by Gilgam

This a tribute to Burning chrome's ono sendai

Posted: 29 Jun 2013, 16:20

by Muirium

Regarding USB: is there space to use a nice tough USB B socket on the keyboard instead of the typical USB mini?

And I really want to put the socket at the back left if I can. Having tried a centre-wired keyboard again recently, I'm forever annoyed by the lead.

Posted: 29 Jun 2013, 16:24

by matt3o

usb b is too long to fit. it would fit the sides by a whisker but I don't think you have enough room in the inside (unless you can find a very short female, but I think they are pretty standard)

horizontal position is irrelevant. you can put it wherever you want (even on a side)

Posted: 29 Jun 2013, 20:36

by Muirium

Cool, position is more important to me. Between Escape and 1 would be nice and tight.

Posted: 02 Jul 2013, 01:24

by Broadmonkey

That is looking really, really great matt3o! I wish I could make the plate myself, so I could start building this before school starts again. basically you have got more or less the perfect layout, although it needs to have an ISO enter and maybe a regular backspace

Do you think it would be possible to make an version with an ISO enter (not small left shift!) if we made a small GB?

Posted: 02 Jul 2013, 08:56

by matt3o

no problem for ISO enter. My next one will have a big J Enter actually (bigger than iso

).

The backspace was a sort of an experiment and I must say that it works very well. Actually I think that that should be the default location for the backspace

Regarding the mini group buy we are approaching August and most companies close for even one month in Italy, so we have to hurry up if we want to place an order. The alternative would be to procrastinate until September.

Posted: 02 Jul 2013, 10:49

by pasph

Even shipping in August is a gamble

Posted: 02 Jul 2013, 10:50

by Muirium

Italians, as usual, have just the right idea.

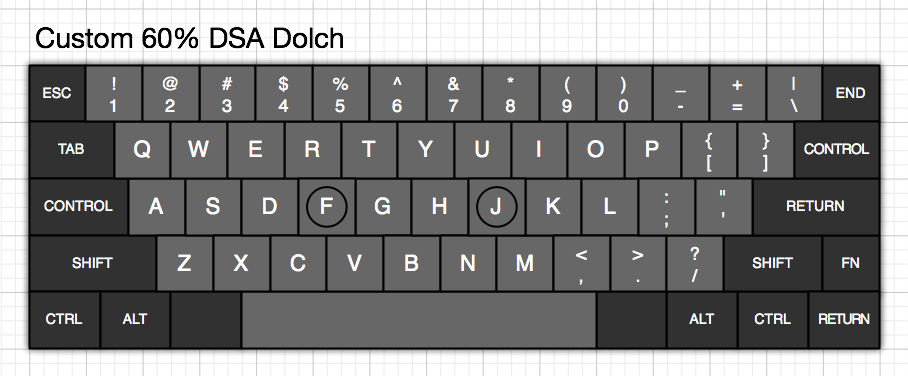

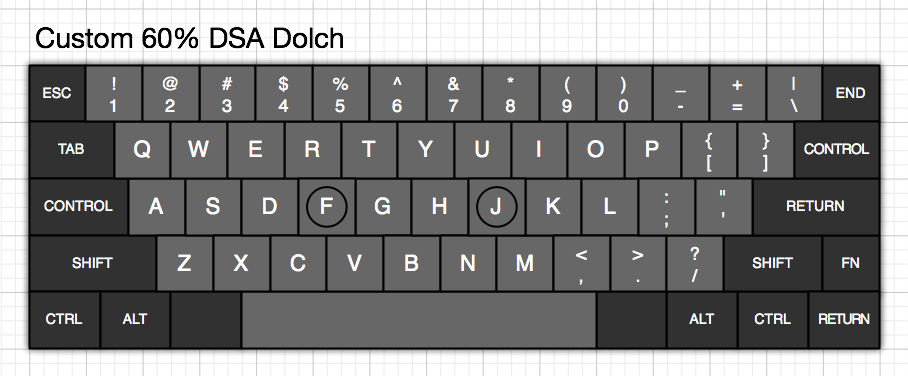

I can be ready nice and soon: as my layout is complete. But I can easily wait: it's not like DSA Dolch is turning up this month.

Posted: 02 Jul 2013, 12:57

by tentator

Wow Matt3o! That sounds great!! Mu poited me out to this thread.. I would really also like to partecipate to this group buy and I have no problems with solder iron at all.. so.. from where are you in Italy? I'm from Milan.. =) Maybe I could even be of some help!!

tent:wq

Posted: 02 Jul 2013, 13:09

by matt3o

I'm from Firenze.

I'm just a bit busy these days. I'll start the GB as soon as possible.

Posted: 02 Jul 2013, 14:08

by tentator

sounds really great!

Posted: 04 Jul 2013, 00:07

by Broadmonkey

matt3o wrote:no problem for ISO enter. My next one will have a big J Enter actually (bigger than iso

).

The backspace was a sort of an experiment and I must say that it works very well. Actually I think that that should be the default location for the backspace

Regarding the mini group buy we are approaching August and most companies close for even one month in Italy, so we have to hurry up if we want to place an order. The alternative would be to procrastinate until September.

So, we can run some ISO plates along with the ANSI plates?

Maybe I can get some local to cut me a plate so I can get it cut sooner. I know my dad in law has a good friend who own a shop, so it might be possible. I am a dork at drawing CAD files atm, so would it be possible that you could share the dwg (or whichever) files?

Posted: 04 Jul 2013, 08:00

by matt3o

sure! all DWG will be shared.

Posted: 04 Jul 2013, 12:17

by matt3o

After some time using it I can safely say that this is the best keyboard I've even owned

Better than Filco+Blue or Red, better than Topre Leopold, better than the m0110, ... There's really no game. I love the layout, I love the sound and I love the DSA caps. The arrow cluster with MXRed is perfect. The MX Green spacebar is the icing on the cake.

If I really have to find a defect is in the location of the main FN key. I can't really find the final spot for it. So far I put it in between ctrl/alt in the lower left corner. That seems the best spot for easy access to key combos such as ctrl+fn, shift+fn, etc.

Bonus picture of the USB port:

And this will be the soon to come layout for the WhiteFox. Love it already! ALPS of course

Posted: 04 Jul 2013, 12:33

by Muirium

Great stuff. The real competition will be when your Model M comes to life! That will be a championship showdown.

What do you use for your internal USB extension, Matt? And what did you use on Steely?

Posted: 04 Jul 2013, 13:06

by matt3o

In fact I omitted the Model M on purpose

The steely doesn't have an extension. The USB cable goes directly to the teensy. For the brownfox I used a highly modded USB connector

http://it.mouser.com/Search/ProductDeta ... USBB551042

Posted: 12 Jul 2013, 14:16

by Findecanor

Wait a minute... White stabiliser clips? I have only seen black before. Where did you get hold of white Costar stabiliser clips?

For my own DIY keyboards, I think I would like Micro USB B because it is supposedly more durable than Mini USB, but I have not found any socket that would be easy to use. All sockets except one I have seen are SMT, and that single non-SMT socket is a panel-mounted socket that is quite large. I would like one where all pins are through-hole or large enough to easily solder by hand to a wire, but no such luck yet.