buckling spring with cherry on top

-

diriel

- Location: United States

- Main keyboard: Matias Quiet Pro

- Main mouse: Kensington K72356

- Favorite switch: Buckling Spring

- DT Pro Member: -

/blink !!

Model M is my absolute favorite keyboard of all time! Damn you matt3eo! What would really rule is a "White Fox" only all new buckling switch that uses cherry mx caps! That would severely hurt my wallet...

Model M is my absolute favorite keyboard of all time! Damn you matt3eo! What would really rule is a "White Fox" only all new buckling switch that uses cherry mx caps! That would severely hurt my wallet...

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Lol I might actually care about artisans then.

The only boards I care about are IBM and alps...

The only boards I care about are IBM and alps...

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Actually... this is a little bit hysterical. I was about to post this in the FSSK thread because I am doing this work tied to it, and decided to search one last time to see if there was any other threads that I might add a link to. I did this work ~3 years ago, and finally decided to act on it now that I was motivated with this FSSK. Low and behold, I came across this (and here I thought I was being novel... at the time, I guess I was?!?)

Considering the work was done in two vacuums, the similarities are striking!!! Which makes me feel good that it really is the "right way", but to be honest, there aren't too many options. I had a working prototype printed a little over a month ago, and can confirm it works. I am not sure specifically what tolerance issues matt3o ran into (could have just been the ribs from a lower res. printer, or things being slightly shifted. I can't tell you what a difference even .1mm makes on moving parts), but this works quite well.

I did have one slight tweak to the actuation travel, and sent the updated version off for printing with the FSSK inner assembly drop-in case I have been messing with. Should receive one big box of goodies in couple of weeks. I really need to just buy my own printer

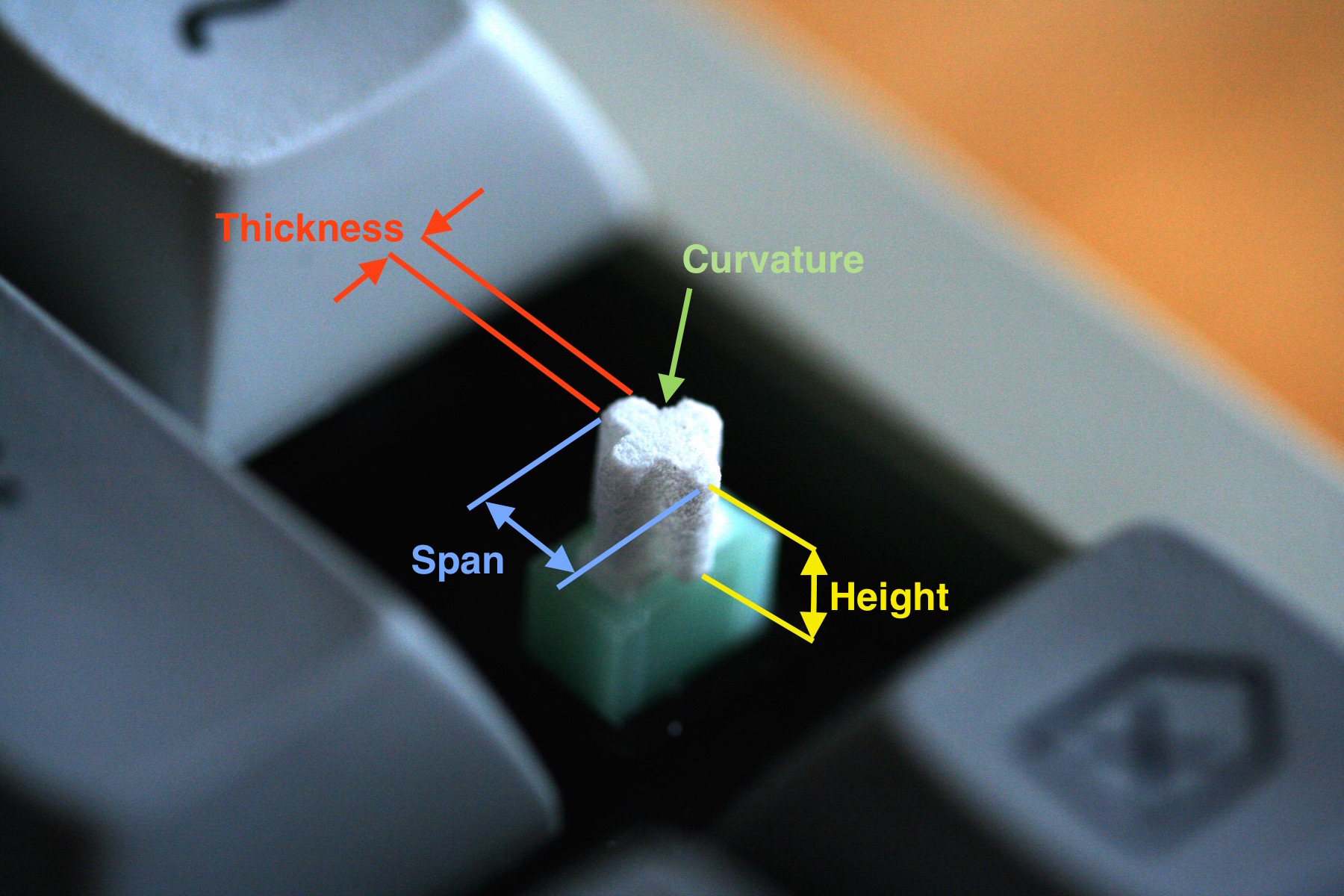

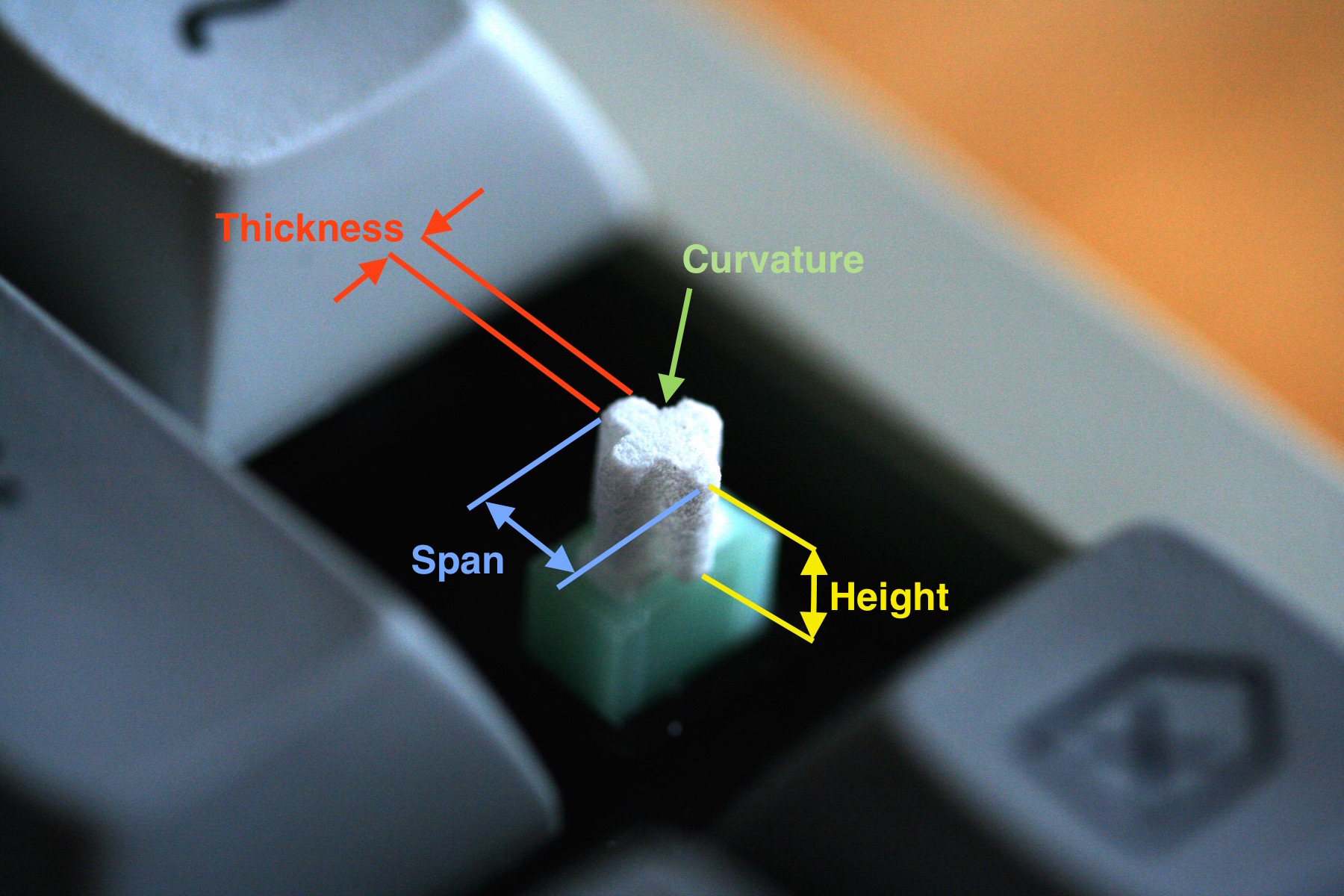

If someone would do me a favor though, could you confirm that these measurements truly are accurate? The other irony of all of this, I love the cherry double shot movement, but have ZERO cherry boards or keys

http://i.imgur.com/iX8JW.png

Side note (and if it is already mentioned in this thread I apologize... I just skimmed it), we could play with actuation travel quite a bit. I wanted this first pass to be identical, but think buckling spring "short throws", etc. It all has to do with the offset of the side clips and the depth of the spring base plate. There is quite a bit of room there for adjustment.

Also, jaseg deserves huge praise for his/her work with the model M measurements back in 2012. I had to modify a few things that I found to be different with the keystem interior, but jaseg's work is actually what inspired me to mess with this back in '13. I have unfortunately been sitting on my plans ever since ... Sorry about that. Let me know what you think

... Sorry about that. Let me know what you think

Considering the work was done in two vacuums, the similarities are striking!!! Which makes me feel good that it really is the "right way", but to be honest, there aren't too many options. I had a working prototype printed a little over a month ago, and can confirm it works. I am not sure specifically what tolerance issues matt3o ran into (could have just been the ribs from a lower res. printer, or things being slightly shifted. I can't tell you what a difference even .1mm makes on moving parts), but this works quite well.

I did have one slight tweak to the actuation travel, and sent the updated version off for printing with the FSSK inner assembly drop-in case I have been messing with. Should receive one big box of goodies in couple of weeks. I really need to just buy my own printer

If someone would do me a favor though, could you confirm that these measurements truly are accurate? The other irony of all of this, I love the cherry double shot movement, but have ZERO cherry boards or keys

http://i.imgur.com/iX8JW.png

Side note (and if it is already mentioned in this thread I apologize... I just skimmed it), we could play with actuation travel quite a bit. I wanted this first pass to be identical, but think buckling spring "short throws", etc. It all has to do with the offset of the side clips and the depth of the spring base plate. There is quite a bit of room there for adjustment.

Also, jaseg deserves huge praise for his/her work with the model M measurements back in 2012. I had to modify a few things that I found to be different with the keystem interior, but jaseg's work is actually what inspired me to mess with this back in '13. I have unfortunately been sitting on my plans ever since

Spoiler:

Last edited by lot_lizard on 02 May 2016, 20:14, edited 1 time in total.

- matt3o

- -[°_°]-

- Location: Italy

- Main keyboard: WhiteFox

- Main mouse: Anywhere MX

- Favorite switch: Anything, really

- DT Pro Member: 0030

- Contact:

I have quite some slider working, the problem is not much in the tolerance but in the texture of the 3d print material. The slider needs to be very smooth for 100% original feel and at the time the available materials were not so good (at least the ones I tried).

I'm too lazy right now to do it myself

I'm too lazy right now to do it myself

please convert to mmlot_lizard wrote: ↑If someone would do me a favor though, could you confirm that these measurements truly are accurate? The other irony of all of this, I love the cherry double shot movement, but have ZERO cherry boards or keys

http://i.imgur.com/iX8JW.png

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

I had to originally as well

- matt3o

- -[°_°]-

- Location: Italy

- Main keyboard: WhiteFox

- Main mouse: Anywhere MX

- Favorite switch: Anything, really

- DT Pro Member: 0030

- Contact:

I've always done the cylinder 5.4mm (you have to consider material shrinkage though, that may vary). Of course if that is negative, 5.5 seems about right, probably 5.6 even better

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Thanks for checking... I have a 5.6 ID on the outer ring, so hopefully that is good. Technically not needed for the mount, so a little extra clearance should be goodness. There is a real tradeoff there on tolerance for the MX mount, and getting too close to the exterior of the keystem glide with MX mount having to be recessed like it ismatt3o wrote: ↑I've always done the cylinder 5.4mm (you have to consider material shrinkage though, that may vary). Of course if that is negative, 5.5 seems about right, probably 5.6 even better

Last edited by lot_lizard on 02 May 2016, 19:19, edited 1 time in total.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

This needs done in something solid, like ABS. My own experience with 3D printed adapters was poor. They crumble, so the effective resolution is low and tolerances go out of whack.

workshop-f7/cherry-to-alps-adapters-t49 ... 3D#p194579

My hunch is that buckling spring is very picky about all this.

workshop-f7/cherry-to-alps-adapters-t49 ... 3D#p194579

My hunch is that buckling spring is very picky about all this.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Yeah... standard print really has no chance for this type of stuff

I use this for precision parts if I order from Shapeways. The price is about 3x, but it works beautifully for testing precision designs

https://www.shapeways.com/materials/hig ... n-acrylate

Again, just to reiterate... I have a working prototype already printed. It's working nicely (action is very smooth, and stable in the barrel). I just want to tweak the activation point. Once I get the modified one in with the rest of the order (2 weeks), I would be happy to make a little video. I plan on taking several pictures then of all the FSSK prints as well

EDIT: I should qualify, I haven't tested the MX mount on a keycap yet, but the edges are crisp like the CAD drawing, and I double checked the sizes meet spec that matt3o help me validate a bit ago

I use this for precision parts if I order from Shapeways. The price is about 3x, but it works beautifully for testing precision designs

https://www.shapeways.com/materials/hig ... n-acrylate

Again, just to reiterate... I have a working prototype already printed. It's working nicely (action is very smooth, and stable in the barrel). I just want to tweak the activation point. Once I get the modified one in with the rest of the order (2 weeks), I would be happy to make a little video. I plan on taking several pictures then of all the FSSK prints as well

EDIT: I should qualify, I haven't tested the MX mount on a keycap yet, but the edges are crisp like the CAD drawing, and I double checked the sizes meet spec that matt3o help me validate a bit ago

- matt3o

- -[°_°]-

- Location: Italy

- Main keyboard: WhiteFox

- Main mouse: Anywhere MX

- Favorite switch: Anything, really

- DT Pro Member: 0030

- Contact:

high definition acrylate was not available at the time. I used frost ultra detail (or something like that) that somehow worked but still expensive.

I'm not very much interested in the project right now, I have too many things going on ATM, but if there's interest I could ask how much would cost injection molding for this thing.

I'm not very much interested in the project right now, I have too many things going on ATM, but if there's interest I could ask how much would cost injection molding for this thing.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

As part of the FSSK project, I am planning on having several things injection molded (barrels, flippers, a spacer to separate the drop-in replacement top and bottom plates). If there is interest in this as well (was just a bonus), I would be happy to see about having the same outfit handle as part of that group buy to keep costs down since I had something that worked. I wasn't aware you were already comfortable with what you had. I'm certainly not trying to make money on anything... That was really why I posted all of this in the first place, and to get some thoughts in general.

If there is interest, let me know

If there is interest, let me know

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

What's this about an FSSK project? Are you doing something similar to / derived from i$ work?

workshop-f7/fssk-v1-0-installation-user ... 13551.html

I'm intrigued by what he did, but dismayed at the work required from us mere users to assemble it ourselves. Bending plates!?! If you're batch manufacturing this stuff, I'd like a peek.

workshop-f7/fssk-v1-0-installation-user ... 13551.html

I'm intrigued by what he did, but dismayed at the work required from us mere users to assemble it ourselves. Bending plates!?! If you're batch manufacturing this stuff, I'd like a peek.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

PM sent... please dont leak until I can harden the "obvious" partsMuirium wrote: ↑Are you doing something similar to / derived from i$ work?.

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

I wish I could try a set of these if you end up manufacturing them, but I actually don't have any Cherry mount keycaps in a flat profile (just OEM, which wouldn't work with adapters, I presume, given the precurved BS plate). Those custom keycap group buys always seem to be $100+, which is just too much for me to spend on a set of caps.

- Touch_It

- Location: Nebraska, United States.

- Main keyboard: Unicomp Classic USB 103 key (work) IBM F 4704 107

- Main mouse: Logitech g502 Proteus Core

- Favorite switch: Buckling spring (yet to try Beam Spring)

- DT Pro Member: -

Good question. Would these need flat profile key caps?. These adapters ate something I'm potentially interested in.Techno Trousers wrote:I wish I could try a set of these if you end up manufacturing them, but I actually don't have any Cherry mount keycaps in a flat profile (just OEM, which wouldn't work with adapters, I presume, given the precurved BS plate). Those custom keycap group buys always seem to be $100+, which is just too much for me to spend on a set of caps.

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

OEM keycap sets simulate a curved plate by altering the height and angle of each row. Since BS boards all have a curved plate and uniformly shaped keycaps, I expect that you'd need the same uniform shaped Cherry mount keycap sets to work with this.

My question would be: how hard would it be to separate a cap from an adapter? Cherry switches can really hold caps tightly. Sometimes it's hard to remove them even with the wire pullers. It seems like it might be extra difficult to remove from an adapter like this, without the leverage of pulling against a plate mounted switch. I'll definitely be watching with interest for further testing and developments!

My question would be: how hard would it be to separate a cap from an adapter? Cherry switches can really hold caps tightly. Sometimes it's hard to remove them even with the wire pullers. It seems like it might be extra difficult to remove from an adapter like this, without the leverage of pulling against a plate mounted switch. I'll definitely be watching with interest for further testing and developments!

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

AWESOME points

). I really need to get a full set of artisan caps from 7bit to test with once the printed adapter arrives. The math will be easier if we can see it, but we do have options. Worst case, you are right, it would be middle row profile only, but we could maybe work with 7bit for special group buys of that profile for a full board

). I really need to get a full set of artisan caps from 7bit to test with once the printed adapter arrives. The math will be easier if we can see it, but we do have options. Worst case, you are right, it would be middle row profile only, but we could maybe work with 7bit for special group buys of that profile for a full board

Sent from my phone, so forgive grammar mishaps, and ducking autocorrection

We do have some tolerances we can add to ID of the outer guard. For any we add, we will need to widen the keystem tab glide to compensate. Luckily, the size of this glide is only critical at the base of the barrel where it slides past the barrel's "tab lock". If we call tab glide direction X... Y is actually substantial, and we could do several things there while leaving the profile unchanged. The NovaTouch has a similar guard I have noticed. If someone had one of those, I would love to know it's radius. Also, we can always tweak the cruciform itself to make it lighter, or potentially add a key puller grove/slot towards the base of the stem (there are unused areas in the stem since the spring breaks the opposite direction). Think pull the cap with adapter attached from the barrel, turn over, and then use the cap puller...Techno Trousers wrote: ↑how hard would it be to separate a cap from an adapter? Cherry switches can really hold caps tightly. Sometimes it's hard to remove them even with the wire pullers

Spoiler:

Since we do have quite a bit of tolerance on the Y axis, we can compensate for tilt (at least some) without raising the key profile on the Z axis). Then we could have R1, R2, etc specific adapters (adding some text to the adapter keep you from going crazy guessingTouch_It wrote: ↑Good question. Would these need flat profile key caps?Techno Trousers wrote:... but I actually don't have any Cherry mount keycaps in a flat profile (just OEM, which wouldn't work with adapters, I presume, given the precurved BS plate)

Sent from my phone, so forgive grammar mishaps, and ducking autocorrection

Last edited by lot_lizard on 03 May 2016, 15:39, edited 2 times in total.

- alh84001

- v.001

- Location: EU-HR-ZG

- Main keyboard: unsaver

- Main mouse: logitech m305 / apple trackpad

- Favorite switch: BS

- DT Pro Member: -

You just need to bend the PCB to fit into existing plate. And based on what hypkx said in his thread, there is no need for even that. I tried pressing the PCB with the barrel frame, and it bent quite easily to the metal back plate. Now, I'm not sure if this is a permanent solution or if we should bend the PCB to relieve stress on it.Muirium wrote: ↑What's this about an FSSK project? Are you doing something similar to / derived from i$ work?

workshop-f7/fssk-v1-0-installation-user ... 13551.html

I'm intrigued by what he did, but dismayed at the work required from us mere users to assemble it ourselves. Bending plates!?! If you're batch manufacturing this stuff, I'd like a peek.

Other than that, you just need to bolt mod an existing SSK, or if that makes you nervous, cut the plates from a regular model M (I did the latter, by using plates from my rubber-dome model M). You also need to solder an xwhatsit, which sounds daunting, but if I managed that and everything else, trust me, anyone can do it.

In any case, getting model F flippers and xwhatsit is where the "pain" lies.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

I wanted to finally get my head around this, and dorked with it over lunch. I am not sure we really need, or even want to doing anything special as far as a row by row offset. At least I would be happy with the results. The following images (assuming the original Signature Plastics profile on our site is accurate), would reflect the end result. There would be SLIGHT additional key separation on the Y plane, but it would be neglible

This is the original:

This is the original in relation to the IBM barrel assembly curve (300mm radial bend for the angle): And this is the result of the two merged: This would be the actual rotation of the backplate as it sits in the case. It is possible that Cherry boards sit on an incline in the case as well. I have no idea... don't own one. And lastly, with IBM keycap profiles in Blue Personally, I like it. At least not bothered by it enough to find a reason to change the adapter to componensate. Any changes to the angles would result in the keys having a "stepped" appearance. We could alter the Z-axis depth, but then we are raising or lower the key in relation to the board

The SA profile would be a bit nuts, but we are in essence turning DCS/DSA into SA hybrids . Welcome thoughts

. Welcome thoughts

EDIT: Per TechnoTrousers request, I added the IBM keycap profile to the last image

This is the original:

This is the original in relation to the IBM barrel assembly curve (300mm radial bend for the angle): And this is the result of the two merged: This would be the actual rotation of the backplate as it sits in the case. It is possible that Cherry boards sit on an incline in the case as well. I have no idea... don't own one. And lastly, with IBM keycap profiles in Blue Personally, I like it. At least not bothered by it enough to find a reason to change the adapter to componensate. Any changes to the angles would result in the keys having a "stepped" appearance. We could alter the Z-axis depth, but then we are raising or lower the key in relation to the board

The SA profile would be a bit nuts, but we are in essence turning DCS/DSA into SA hybrids

EDIT: Per TechnoTrousers request, I added the IBM keycap profile to the last image

Last edited by lot_lizard on 03 May 2016, 23:19, edited 1 time in total.

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

The graphics help to visualize that, thanks! Without spending a ton of time, could you put the IBM key shape in there as well, for comparison? I have a feeling that it's close to the SA profile in height, but will be less angled on the top.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

I added the IBM outline in blue to the last image of the previous post.Techno Trousers wrote: ↑The graphics help to visualize that, thanks! Without spending a ton of time, could you put the IBM key shape in there as well, for comparison?

- Techno Trousers

- 100,000,000 actuations

- Location: California

- Main keyboard: IBM Model F-122

- Main mouse: Mionix Naos

- Favorite switch: Capacitive Buckling Spring (Model F)

- DT Pro Member: 0159

Cool! Is that angle right, though? I always thought the tops of the IBM caps were close to parallel with the curved plate.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Hahaha... Thanks. If anything, I might need to roll the tilt of the board forward more (i just have the assembly sitting on my desk and didn't measure as seated in the case, I'll do that tomorrow, but it's within a couple degrees I expect). But am confident of the key pitch in relation to the plate, and that's the important part for this exercise.Ratfink wrote: ↑Moving my head to the side of my desk, I can tell you that angle's certainly damned close to right.

I am going to start in on the "cute keys" next, like the spacebar, shift(s), backspace, enter, etc. Off the top of my head, I think there are only 2-4 unique bases needed, but will verify (right and left 1.75 keys, the spacebar, and a vertical). I believe 1.75's and vertical might be mirror/rotated copies of each other. For each key though, I suspect we need unique tops to offset the cherry mounts (the stuff that is new to me)

I have 3/4 different versions of the spacebar in my head that I would like to try to see what actually performs the best. In the end, we might need to have a stabilzer insert for the left barrel on the spacebar, but won't know until I have a working mockup to play with printed

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

I finally ordered some Cherry caps as part of the R6 leftovers, so at least I will have something to test the tops with. The following is what I pieced together based on what's left. The keys on the right I am begging him to see if he can magically find some additional ones as part of the order. I will be putting all of this in a 1395682 (the industrial with blue caps). I'm not sure when they will arrive, but should make for some nice pictures when they do

The spacebar is a 7 unit (133 mm). It will work perfectly, and I will spec the spacebar specific adapter to hold the two outermost and center pegs.

wiki/Space_bar_dimensions#7_units_.2813 ... m_apart.29

The spacebar is a 7 unit (133 mm). It will work perfectly, and I will spec the spacebar specific adapter to hold the two outermost and center pegs.

wiki/Space_bar_dimensions#7_units_.2813 ... m_apart.29

Spoiler:

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

7bit can take a while. Anyone in America up for donating you some MX caps? They don't have to be awesome ones! Just a good fit.

- lot_lizard

- Location: Minnesota

- Main keyboard: Indy SSK Model MF

- Main mouse: Logitech Anywhere MX

- Favorite switch: Beamspring

- DT Pro Member: -

Bummer... Once I get all of the special keys together, and get the prints back, I will see what I can come up with. We are realistically at least 2-3 weeks out from having those in hand anyway (Shapeways is 2 weeks from order to delivery).Muirium wrote: ↑7bit can take a while

Worst case, I "borrow" one from BestBuy for the afternoon one day. And return it saying... "its just not for me"

EDIT: by "borrow", I mean purchase the entire keyboard with the intent to return (not grift a key from some floor model). I am sure I can find a friend that will loan me one