The 65% keyboards have been intriguing me for a while and I tried out a mock sort of setup using my 1800 and realised that this was the right layout for me as it is the most practical, however all the 65% on offer will still cause ulnar deviation. I then decided I have to make a 65% with a split. I used the Input Club Ergodox' Left-hand KiCAD project as a blue print and then started to work on the PCB. The decision to use the ICED was as it had support for two PCBs communicating with each other.

This brings us to today, I have completed the PCBs for both the left and right side of the keyboard. I will be uploading the project to Github soon once. However I am at a conundrum for a decent bottom row, one that is practical and one that has decent compatibility with existing keysets.

Features:

- Open Source Design

- Fully Programmable Keys

- Split design for better ergonomics, while maintaining the currently "standard" keyboard layput

- PCBs and case designed so that the two sides can be aligned perfectly like a 65%, for others using the board, cleaner desk while not at it, etc.

- Multiple layers

- Alps/Cherry (PCB/Plate) switch support

- PCB mount stabs supported

- Backlight LED on top to maintain compatibility with the few backlit keysets out there

- 3 Indicator + CapsLock LED

- 18 SMD RGB LEDs on the bottom of the PCB for under/side glow

- SMD (SOD-123) diodes

- Individual resistors for the LEDs not required as it uses a dedicated LED driver

- Using large (0805) capacitors and resistors so it is easier to hand-solde

Optional features supported:

- Possibility to add a buzzer

- Possibility to add a PS/2 trackpoint to either halves.

- Possibility to add a rotary dial for changing volume, LED brightness, etc.

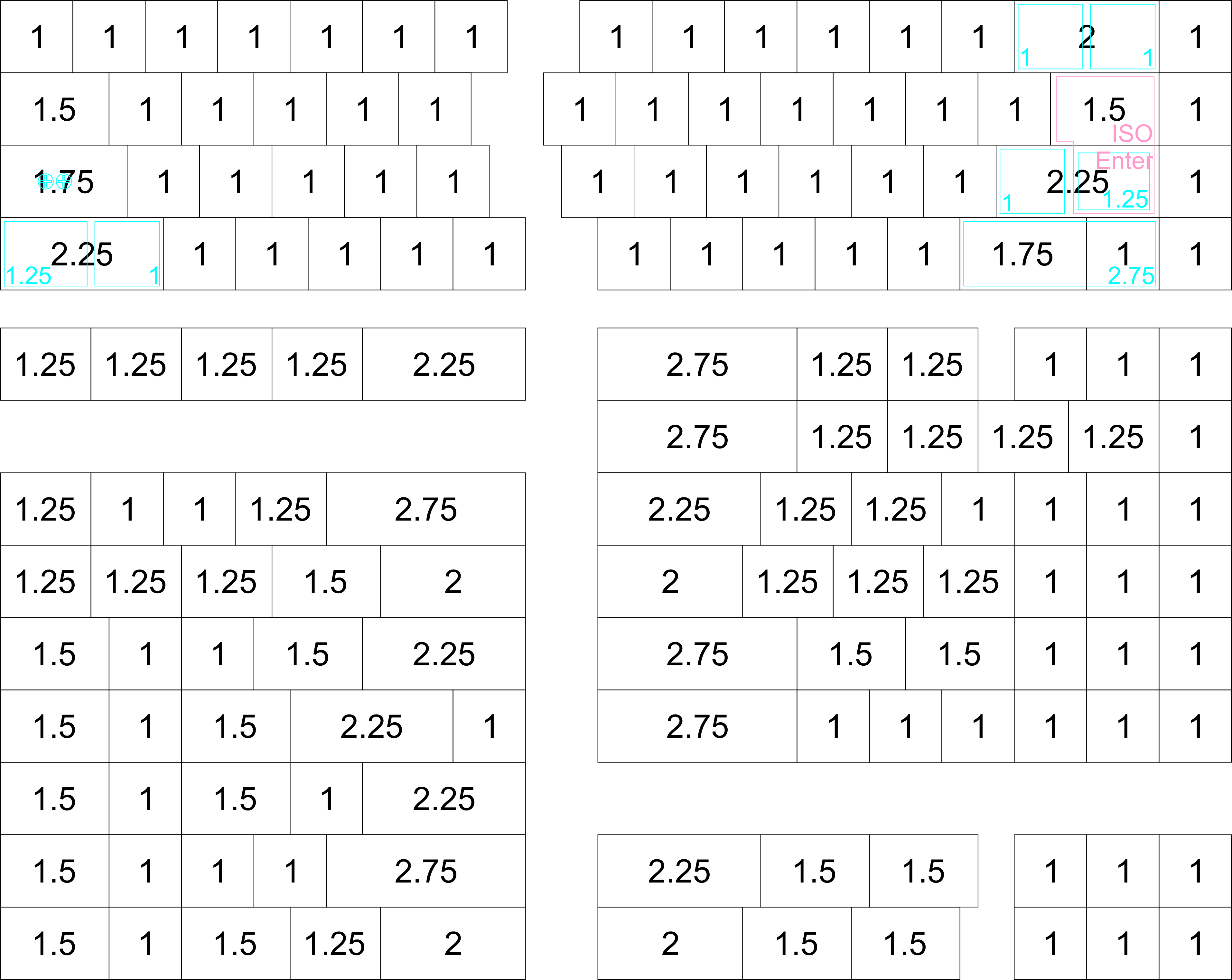

Layout options decided/implemented:

- Split backspace

- Split left shift

- ISO support

- Off-center capslock

- 2.75 and 1.75 right shift

- Multiple bottom rows supported

To Do (immediate):

- Add support for RGB LEDs to EasyAVR

- Add support for MCP23018 to EasyAVR

- Add support for buzzer to EasyAVR

- Add support for PS/2 trackpoint to EasyAVR

- Add support for rotary encoder to EasyAVR

GitHub Link: https://github.com/mohitg11/TS65AVR

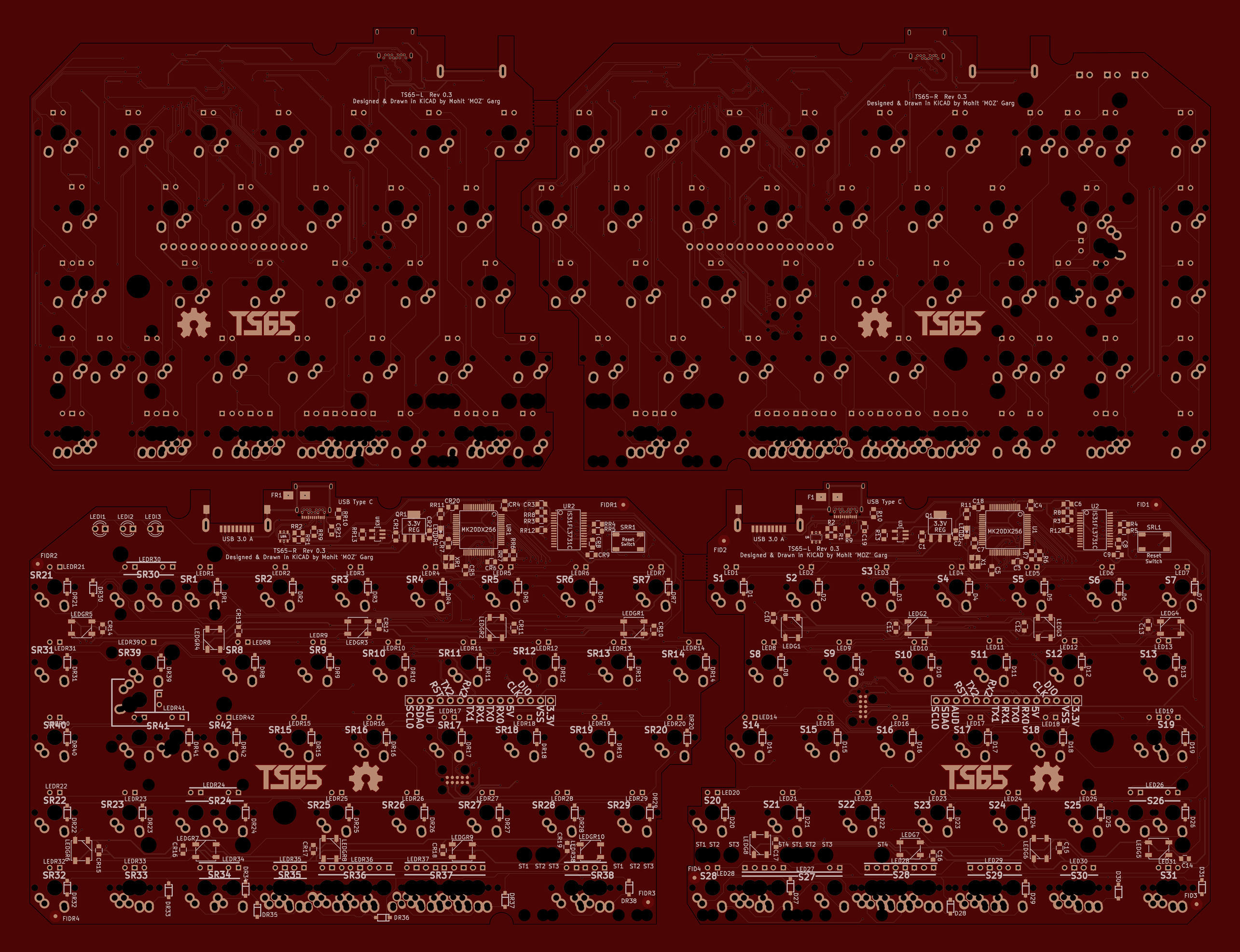

Current PCB design:

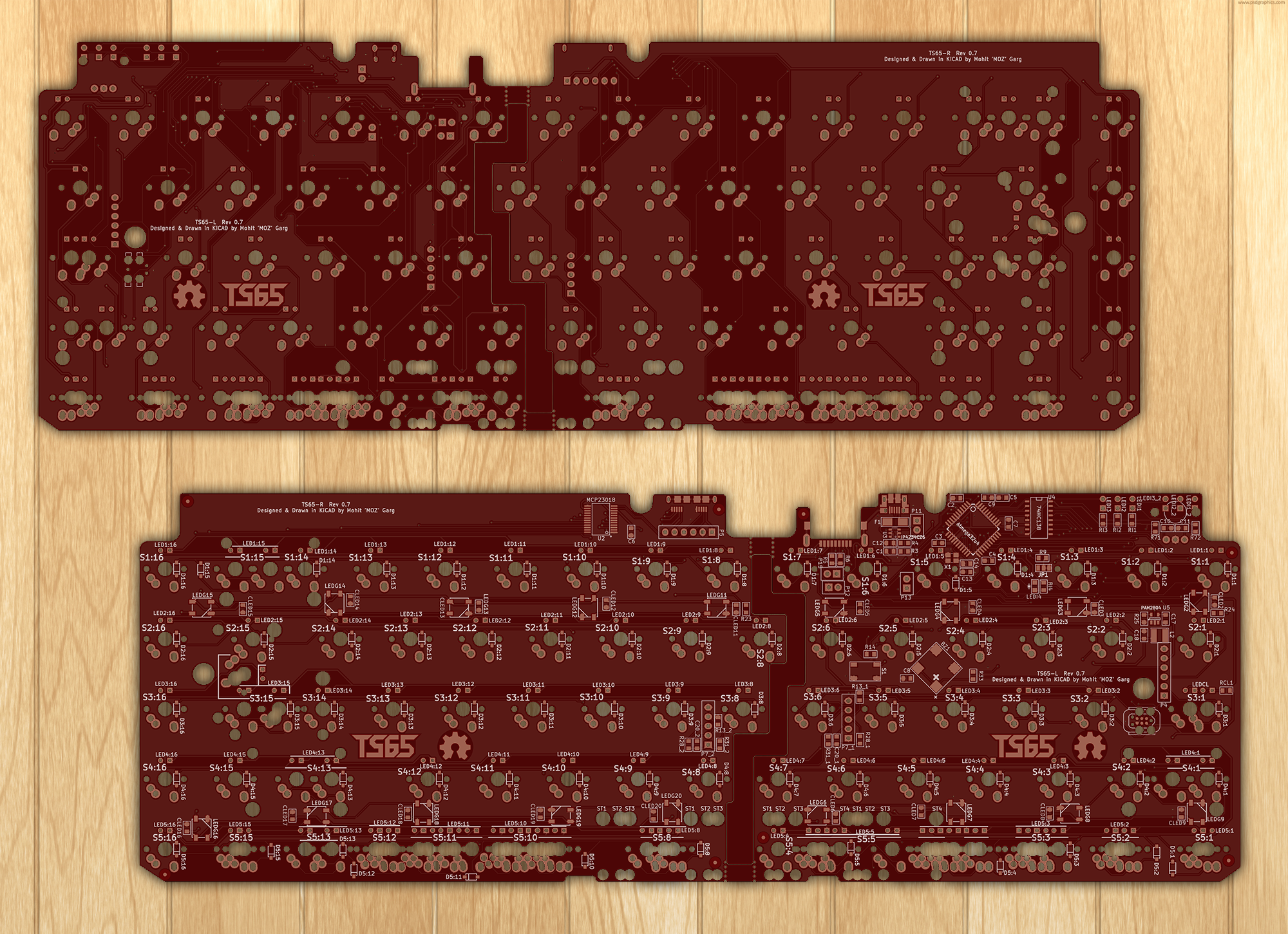

What it's gonna look like: