Page 19 of 38

Posted: 02 Jan 2017, 20:31

by Rimrul

I don't think I have a 1.5mm allen wrench, so I voted Phillips.

Posted: 02 Jan 2017, 20:52

by alh84001

How in the heck is Phillips winning right now? And one more vote for Torx

Posted: 02 Jan 2017, 20:56

by wcass

You guys know that none of the screws will be visible with the case on, right?

Posted: 02 Jan 2017, 21:07

by lot_lizard

Posted: 02 Jan 2017, 22:07

by lot_lizard

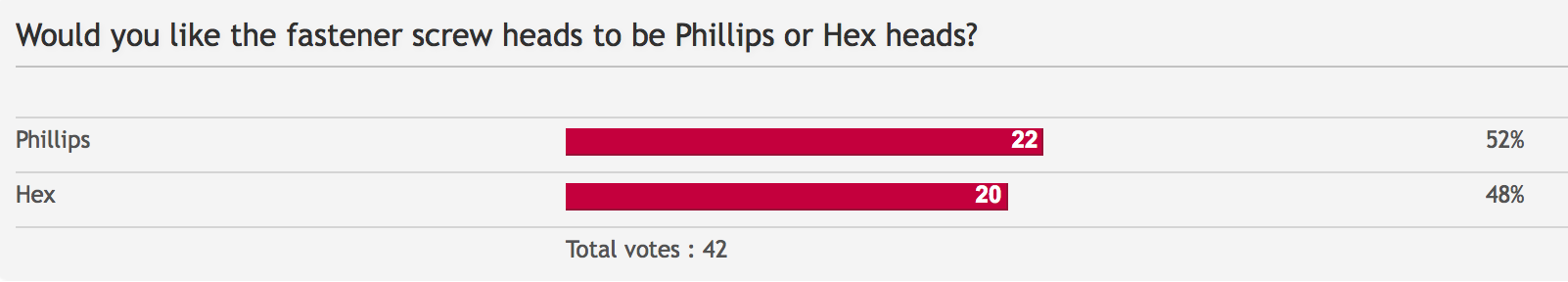

- Screen Shot 2017-01-02 at 4.28.34 PM.png (48.53 KiB) Viewed 6956 times

Because the responses were much more even than I anticipated, I made the following form for those to sign up if they wanted torx (hex as a cost prohibitive backup) instead of Phillips driver head.

https://goo.gl/forms/OngAq2Uf3UM2ATfG3

Do it quickly if you are interested. I'm on my phone now so the form isn't the best, but should serve its purpose. This is an all or nothing election to have the alternate fasteners (so if you had more than one kit, this election would apply to all of those kits). Keep in mind there is no bad choice here, and no one that doesn't WANT torx/hex should feel the need to switch.

I'll send out a PM with the form link as well. Let's have these done by Wednesday if interested

Posted: 02 Jan 2017, 22:47

by Ir0n

Signed.

._. now if only they was chromate coated to match my bored colors more... or blue that'd be neat. lol

Thank you lot_lizard :^)

Posted: 02 Jan 2017, 22:55

by E TwentyNine

lot_lizard wrote: https://goo.gl/forms/OngAq2Uf3UM2ATfG3

You're welcome

. Do it quickly if you are interested. I'm on my phone now so the form isn't the best, but should serve its purpose. This is an all or nothing election to have the alternate fasteners (no partial orders). Keep in mind there is no bad choice here, and no one that doesn't WANT torx (hex as a cost prohibitive backup) should feel the need to switch.

I'll send out a PM with the form link as well. Let's have these done by Wednesday

Will an alternate fastener require more work on your part (sourcing and including the tool(s))?

If one didn't want an alternate (sticking with phillips or even JIS), would they submit that form without checking the box?

What does "all or nothing" mean in this context?

Posted: 02 Jan 2017, 22:56

by E TwentyNine

Ir0n wrote: Signed.

._. now if only they was chromate coated to match my bored colors more... or blue that'd be neat. lol

Thank you lot_lizard :^)

I've been looking at the raw metal lizard's been posting and I'm wondering how well that would age unprotected.

Posted: 02 Jan 2017, 23:25

by lot_lizard

E TwentyNine wrote: Will an alternate fastener require more work on your part (sourcing and including the tool(s))?

Like with the Phillips fasteners, if you elected the torx/hex option, I would assume you had the tools you needed already... and we wouldn't supply them for you. This is just something for those that REALLY want it since the polling was showing about half had interest (which surprised me). For those interested, the m2.5 screw would need a t8 and the m3 would need a t10 driver bit

E TwentyNine wrote:

If one didn't want an alternate (sticking with phillips or even JIS), would they submit that form without checking the box?

If you are comfortable with the Phillips (no reason not to be), there is no need to do anything. This is just a form to submit if you want the alternate fasteners.

E TwentyNine wrote: What does "all or nothing" mean in this context?

For people that had ordered more than one kit, I was just making this available as an option to apply to ALL kits they ordered versus having it apply to only a subset. Just wanted to make it easier for both them and me since I already have all of the numbers in hand

E TwentyNine wrote: [I've been looking at the raw metal lizard's been posting and I'm wondering how well that would age unprotected.

The last round of prototypes that were pictured were stainless steel (half polished) and would age very well. For everything we are doing here, it wouldn't do very well. It would need to be treated in some way not to rust

EDIT: updated some of the previous posts to make the points that E29 was making more clear

Posted: 03 Jan 2017, 03:27

by E TwentyNine

OK, now I have to ask -- can we get chromate screws?

Posted: 03 Jan 2017, 03:37

by lot_lizard

E TwentyNine wrote: OK, now I have to ask -- can we get chromate screws?

I thought it was a clever suggestion too

... I am not sure how small their small parts baskets are (these screws are pretty tiny), but will certainly ask. I would plan on doubtful, but you never know

Re: Model MF - GB CLOSED

Posted: 03 Jan 2017, 05:14

by Techno Trousers

I didn't get a chance to vote, but I'm glad that philips is the default. As wcass said, these are all hidden by the case, so after assembly I don't expect to see them again for decades at the earliest. May as well go with the easiest to service option for future generations.

Posted: 03 Jan 2017, 10:49

by andrewjoy

torx all the way man!

Philips are outdated and the reason for there existence (no torque limiting on electronic drivers) is no longer a thing.

Sooner everything switches to torx the better.

And the less said about flat head the better... the 1500s called , they want there screws back.

Posted: 03 Jan 2017, 11:22

by Nuum

I would love to get torx screws as well, simply because from my experience they are superior, but I just don't have the tools for them around.

Posted: 03 Jan 2017, 12:11

by giokkk

Voted for Torx!

Posted: 03 Jan 2017, 15:03

by fohat

Nuum wrote:

but I just don't have the tools for them around.

You should just buy a small Torx set anyway.

T9 will open old hard drives and they have amazing magnets in them.

Posted: 03 Jan 2017, 17:29

by lot_lizard

Just a couple of updates. The alternative fastener form is working, though I haven't confirmed with any one (27 participants so far)

And we received our vinyl stickers in. When I open up later, I'll snap some pics. Will be out of town most of the next two weeks for work

Re: Model MF - GB CLOSED

Posted: 03 Jan 2017, 19:37

by Techno Trousers

andrewjoy wrote:torx all the way man!

Philips are outdated and the reason for there existence (no torque limiting on electronic drivers) is no longer a thing.

Darn it, now I'm waffling. Does anyone have a link to a known good set of bits (max durability) that include T8, T9, and T10? Most of the small torx bit sets I see on Amazon are the security type with the open hole in the middle, and I'm sure that's going to make them significantly weaker.

Posted: 03 Jan 2017, 20:02

by lot_lizard

Techno Trousers wrote: Does anyone have a link to a known good set of bits (max durability) that include T8, T9, and T10? Most of the small torx bit sets I see on Amazon are the security type with the open hole in the middle, and I'm sure that's going to make them significantly weaker.

Tamper proof isn't bad for small things like this since it would work for both in the future if you ever needed. It really depends what you mean by "good". If you don't expect to use them too much, and since you are in the states, Craftsman would be a reasonable quality tool for the hobbyist/tinker that is competitively priced. I would pick something with a lifetime warranty (though that is meaning less all the time since even cheap junk is protected by that).

If I was only going to have one set, and I already had a proper 1/4 and 3/8 inch socket set... I would probably opt for Torx socket bits. Usually those combination sets that people already have include a hand driver (think screwdriver for sockets). You would be able to apply additional torque to things in the future that need it via the ratchet, and they store well. The only downside would be clearance in tight locations or deep recessed screws. I use them OFTEN.

If you are getting the hand-driven only variety, I would recommend T-handles. It really depends what your end goal is with them, and what your price point would be.

All that said, Phillips is certainly not a bad choice

Posted: 03 Jan 2017, 22:07

by livingspeedbump

Voted, filled out the additional survey for torx.

But honestly, end of the day I'm going to be just fine with whatever shows up.

Posted: 03 Jan 2017, 22:24

by E TwentyNine

lot_lizard wrote: I would probably opt for Torx socket bits. Usually those combination sets that people already have include a hand driver (think screwdriver for sockets). You would be able to apply additional torque to things in the future that need it via the ratchet, and they store well. The only downside would be clearance in tight locations or deep recessed screws. I use them OFTEN.

I bought a cheapo torx hand driver a while back when pulling apart hard drives. Basically an oversized jeweler's screwdriver with interchangeable tips. They held up ok, think I twisted one of the smallest bits on a particularly tough screw, but it still fits.

lot_lizard wrote:

If you are getting the hand-driven only variety, I would recommend T-handles. It really depends what your end goal is with them, and what your price point would be.

Another option is a folding key set. I have these for both hex and torx, and you can fold out the keys you're not using and get a T-like handle. Much more portable than a bunch of T-handles too.

Posted: 03 Jan 2017, 22:43

by micrex22

Techno Trousers wrote:

Darn it, now I'm waffling. Does anyone have a link to a known good set of bits (max durability) that include T8, T9, and T10? Most of the small torx bit sets I see on Amazon are the security type with the open hole in the middle, and I'm sure that's going to make them significantly weaker.

This is the torx set I use, made by Wiha:

https://www.kctoolco.com/wiha-26791-8-p ... river-set/

Very high quality bits on the drivers, and they have T1 (which is what I needed). I was looking at ebay actually, and I think cheap manufacturers don't have the tooling to make T1.

Honestly, a T1 bit is something to behold in person.

If you don't need T1, then you could get this set:

https://www.kctoolco.com/wiha-26796-8-p ... pouch-set/

It has T8, T9 and T10.

Posted: 04 Jan 2017, 00:46

by Techno Trousers

Thanks, everyone. My go-to screwdriver set is a Gearwrench 8940, which includes three ratcheting handles including a T-handle, various extensions, and a selection of bits. This set might not survive industrial use, but I really like the fine-tooth ratcheting, and the bits have held up really well to years of (occasional hobbyist) use. It does come with a selection of Torx bits, so I'll have to see whether I need to get any other specific torx bits to round out the bit selection I already have. I also just remembered I have a big security bit set too and it has most everything under the sun (it's cheap Harbor Freight though--mostly I keep that around just in case).

I'm on board for torx now.

Posted: 04 Jan 2017, 04:07

by alh84001

andrewjoy wrote:

Sooner everything switches to torx the better.

How do you feel about Pozidriv?

Posted: 04 Jan 2017, 04:50

by DMA

alh84001 wrote: How do you feel about Pozidriv?

- art_of_trolling.jpg (70.4 KiB) Viewed 6748 times

Re: Model MF - GB CLOSED

Posted: 04 Jan 2017, 06:59

by Techno Trousers

alh84001 wrote:andrewjoy wrote:

Sooner everything switches to torx the better.

How do you feel about Pozidriv?

Ha ha, I actually used those when I built the workbench in my garage about 15 years ago. They were definitely much nicer for driving with my drill than Phillips screws.

Posted: 04 Jan 2017, 12:07

by andrewjoy

alh84001 wrote: andrewjoy wrote:

Sooner everything switches to torx the better.

How do you feel about Pozidriv?

Slightly less shit .

Posted: 04 Jan 2017, 12:48

by Ray

We are using PZ for most screws at work. There is an improvement over PH. When you slip (not if, when), the wear on the screwhead is not as bad as with PH. So as long as you are careful, you don't end up with totally worn heads and should be able to unscrew several times without issues.

But if you want more than ~10 Nm torque, PZ2 is a bad choice.

Posted: 05 Jan 2017, 21:11

by lot_lizard

I am shutting this form for the alternative (torx) fasteners down today. If you would like to participate in that, do so by this evening.

https://goo.gl/forms/OngAq2Uf3UM2ATfG3

43 participants so far (more than enough to drive volume pricing)

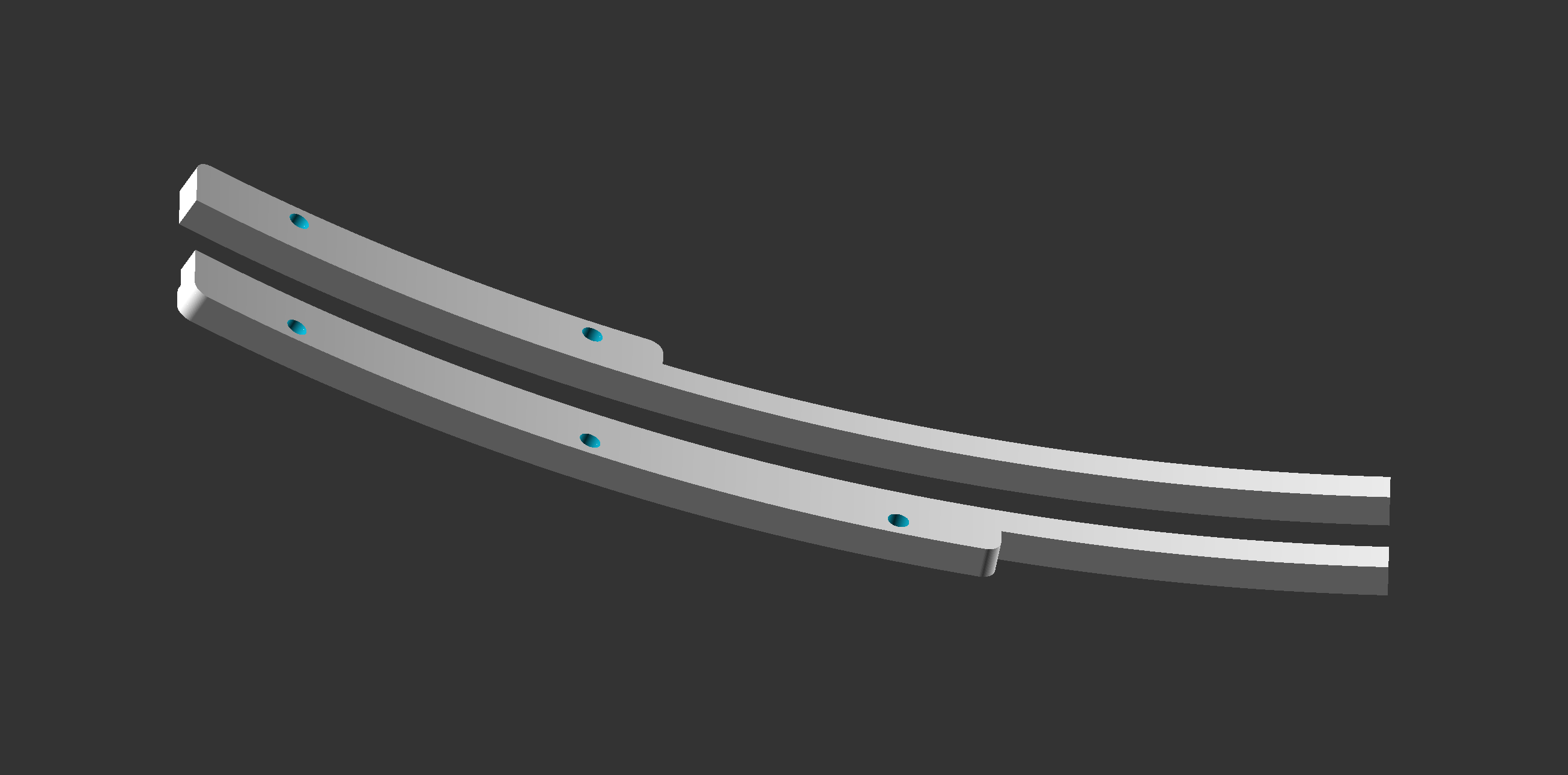

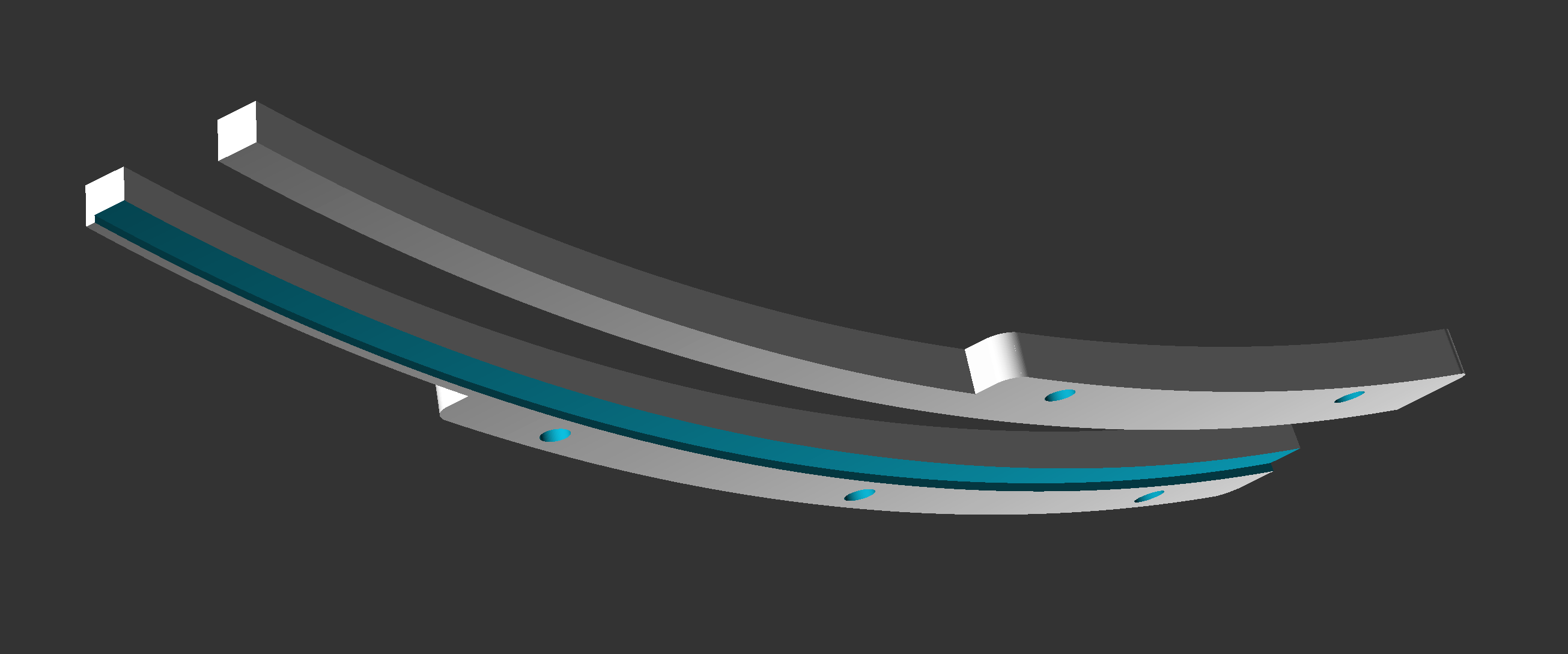

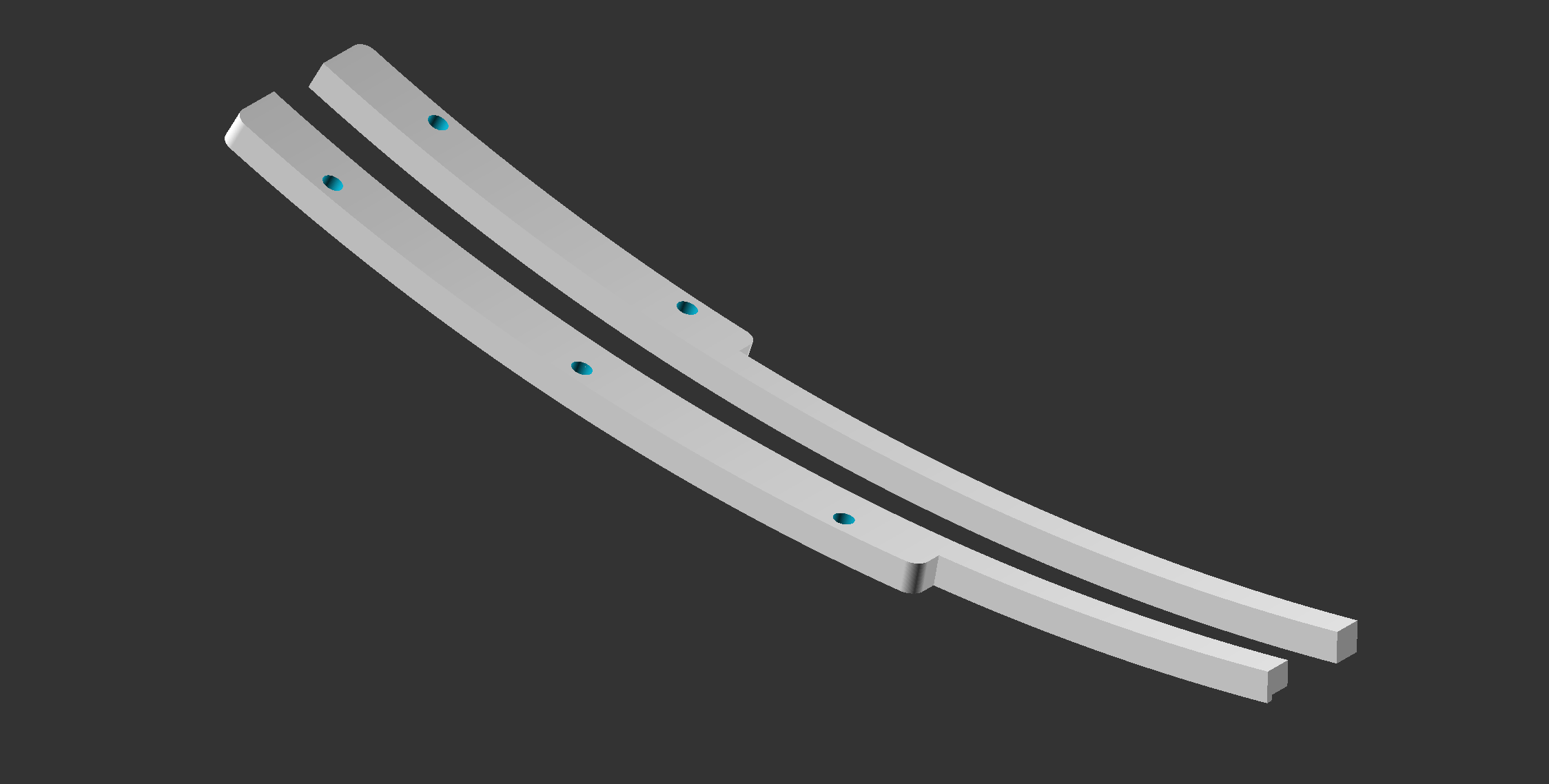

When I return from my work trip, I will begin printing the side spacers. They are modified now to act as a debris shield that is inset inside the entire length of the assembly plates. I would consider putting some message/artwork/logo/pattern into the visible side portion, if anyone had thoughts. Everything is being cleaned up and productized quite a bit with all final designs, and this would be an opportunity as well if we felt that it added to the end result in a positive way. The following are the final version of the spacers/debris shields. The left side will be notched on the bottom to let the PCB have clearance.

- Side view

- sskSpacersSide.png (38.95 KiB) Viewed 6593 times

- Bottom view (with notch on left spacer for PCB)

- sskSpacersBottom.png (42.15 KiB) Viewed 6593 times

- Top view at an angle

- sskSpacersAngled.png (41 KiB) Viewed 6593 times

Posted: 06 Jan 2017, 23:31

by lot_lizard

. Do it quickly if you are interested. I'm on my phone now so the form isn't the best, but should serve its purpose. This is an all or nothing election to have the alternate fasteners (no partial orders). Keep in mind there is no bad choice here, and no one that doesn't WANT torx (hex as a cost prohibitive backup) should feel the need to switch.