Page 4 of 4

Posted: 17 Dec 2014, 23:36

by Touch_It

Probably a complete noob question, but I'm still new around here so I suppose I can still ask them. What is a code key? I'm completely confused, I think.

Posted: 17 Dec 2014, 23:41

by andrewjoy

A split space bar as far as i know

Posted: 17 Dec 2014, 23:51

by jacobolus

Muirium wrote: So what can a Code key actually do, layout wise? Sit in useful spots other caps can't? Is it curved at all, like a spacebar?

It’s shaped like a spacebar, but 2.75 units wide.

The posts under the keycap are such that you can use the code key + spacebar from a wheelwriter to replace the Alt + spacebar + Alt keys from any 4704 Model F, F-122, unsaver, or Model M board, provided you do some work to fix the stabilizers. (Possibly also useful on an AT if you do some plate modding)

Re: IBM Model F 62 and F 107 Mod Ideas

Posted: 18 Dec 2014, 00:44

by Touch_It

Ok, I knew that. Must have had too much egg nog at the company Christmas party today lol

Posted: 18 Dec 2014, 03:24

by 0100010

Code Key, as described above. 2.75 unit width key with the profile of a BS spacebar, comes from IBM Wheelwriters.

Posted: 19 Dec 2014, 22:19

by Hypersphere

If it could be done, my preference would be to replace the spacebar in a 4704 F or F122 with a Code key and then symmetrically arrange modifiers to fill some of the gap on each side. I've never understood why so many keyboards use such wide spacebars.

Posted: 19 Dec 2014, 23:40

by jacobolus

Hypersphere wrote: If it could be done, my preference would be to replace the spacebar in a 4704 F or F122 with a Code key and then symmetrically arrange modifiers to fill some of the gap on each side. I've never understood why so many keyboards use such wide spacebars.

It can be done, if you’re willing to make a new PCB and new top plate!

As for why they use wide spacebars: like most design elements of the standard keyboard layout, that’s just how things have been since some guy made it up in 1868.

Posted: 19 Dec 2014, 23:59

by Touch_It

I like me a large space bar, no real reason just do, but the code key could be very functional and pretty unique. I keep thinking about it now

.

Posted: 21 Dec 2014, 05:36

by wcass

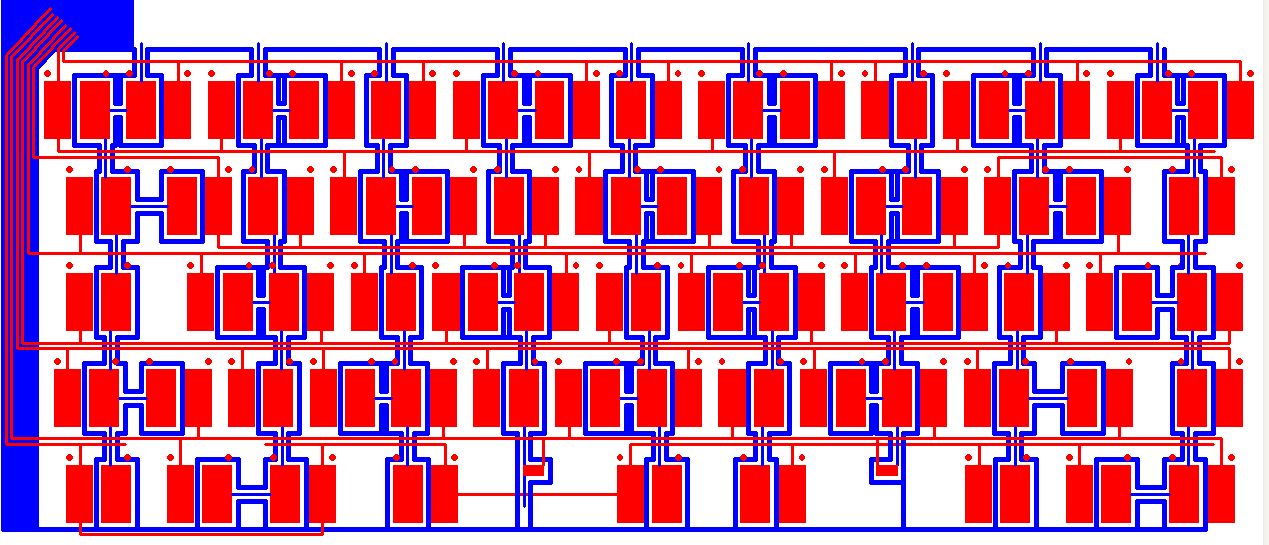

This 8 by 9 matrix will support all of the layout options listed in the animated GIF that 0100010 posted on December 7, plus ISO or ANSI left shift and Enter. The two barrels normally under the right shift have been moved to support 1.5x and 1.25x caps; a "standard" right shift will not work with this design. The barrel frame (as drawn) will take either XT or AT type barrels. You might want a different barrel frame for each option, or just cover or ignore any unused holes. I could put the controller directly on the PCB, but before I do that work, I'd like to know if you guys are serious. We would need someone to design the case and someone to run the group buy.

- F66 matrix.jpg (191.47 KiB) Viewed 5320 times

- F66 caps.jpg (126.17 KiB) Viewed 5320 times

Posted: 21 Dec 2014, 06:18

by Hypersphere

@wcass: Thank you for your diligent work on this! Looks like your plan will accommodate the HHKB-Rev3 along with the alternate layout as shown in the animated GIF. This way, standard IBM keycaps sourced from IBM boards or bought new from Unicomp would work for all the key positions.

Just to double check: Your plan will work with a 7-unit spacebar, correct? And would we be able to have a curved barrel plate and backplate?

How shall we assess seriousness? Should we set up a poll or a spreadsheet for people to register their interest and indicate how many keyboards they would be willing to purchase?

I am certainly in for at least one, and possibly as many as three, depending upon cost.

Posted: 21 Dec 2014, 07:21

by wcass

Hypersphere wrote: ...

Just to double check: Your plan will work with a 7-unit spacebar, correct? And would we be able to have a curved barrel plate and backplate?

Yep; 7-unit spacebar or [2.75 unit "Code"][1.5][2.75 unit "Code"]. Curved plate should not be a problem, but will increase cost and require more skill on the design and assembly side. I have a few ideas on this, but would prefer to leave that up to another volunteer with decent 3D design skills.

How shall we assess seriousness? Should we set up a poll or a spreadsheet for people to register their interest and indicate how many keyboards they would be willing to purchase?

I am certainly in for at least one, and possibly as many as three, depending upon cost.

An interest check posting might be a good start, but we will need some folks to volunteer and take ownership of some of the steps. It is an awful lot of work for just one or two people.

- Group buy lead

Case design

Plate production

PCB production

Pad production

Case production

Distribution

Posted: 21 Dec 2014, 07:53

by 0100010

Case for me would probably be really simple - essentially a naked Model F. Just take the curved plate 'sandwich' (of the bottom plate, polymer sheet, PCB, barrels, foam, spacers and barrel frame); where the length / width of the plates extends on the edges to allow for both the integrated controller and bolting together (and maybe a couple in the middle). Then some kind of mount underneath the top edge to raise it up and rubber bumpers for isolation from the desk and movement control. Put the USB port along the top edge with a gap in the plate spacer.

I would want to make the foam myself and I would prefer the plates are curved.

Posted: 21 Dec 2014, 08:00

by 0100010

Wcass - why are the columns in the PCB design all connected together across the bottom? I know there is supposed to be a ground plane around the entire perimeter, but I seem to recall each column being isolated?

Posted: 21 Dec 2014, 17:34

by Hypersphere

@wcass: I would be no good at all at the steps you have outlined, and so I hope that those who have real talent in these areas will come forward.

Like 0100010, I would not need a case for the keyboard. Perhaps this is something that could come later, such as the various after market metal cases for the Poker II. On the other hand, I doubt there will be much volume for this keyboard, and so it might be good to capitalize on the initial momentum to get all aspects of the project done in a single concerted drive forward.

One thing we need is a name for this keyboard. Thus far, we have a layout that has been dubbed HHKB-Rev3, but this is rather derivative (despite the fact that we are indeed copying the basic layout of the HHKB for starters). We could have a contest to draw out the imaginative talent of the DT membership.

Posted: 21 Dec 2014, 20:38

by kuato

I'm interested if this happens in any form, but I would definitely prefer a case to go with it. The majority of the cost will come from cutting the case anyway, so it makes sense to make them in a 'run'.

Posted: 21 Dec 2014, 23:26

by Muirium

Yeah, same here. I've got more than enough testbed projects; useful keyboards are those with a good case.

Wcass, are you likely doing an XTant run for the masses sometime? I now have the

controller and a donor board on the way.

Posted: 22 Dec 2014, 03:57

by wcass

Muirium wrote: Yeah, same here. I've got more than enough testbed projects; useful keyboards are those with a good case.

Wcass, are you likely doing an XTant run for the masses sometime? I now have the

controller and a donor board on the way.

I have re-discovered just how much i dislike selling things. I will most likely give away all of the parts I have and publish everything. This is one of the reasons i say that other volunteers are so important to a successful project. Some folks are good at and enjoy organization, sales, programming, circuits, or 3D design; others have access to equipment or a relationship with a good supplier. Even if we ignore the case and pad, we need to fill several of those roles.

Posted: 22 Dec 2014, 05:09

by joc

I would also support this project depending on the final total cost. Maybe it will be easier (less work) if a TKL version was designed to fit inside an SSK case?

Edit: Never mind, I just noticed that the XTant project is already a TKL Model F.

Posted: 15 Feb 2015, 17:20

by 0100010

Was thinking this morning about when we get the various plates slip rolled to the correct radius - specifically the edge spacer that would be needed to give clearance between the bottom plate and the barrel frame for the PCB / barrels / foam.

I wouldn't think the edge spacer could be completely cut out from the flat stock prior to slip rolling if we wanted to ensure it achieves the correct radius across its length/width. Depending on how many total boards are going to be built, you could layout the water / laser templates in a fashion that cut out 95% of the design to facilitate slip rolling.

Only after the entire piece has been slip rolled, then you could manually cut out that last bits to remove each individual piece.

Maybe follow the same principal with each layer. This way the slip roll could be set up once for each thickness of material, then run them all through in groups so that each piece is as uniform as possible.

Posted: 15 Feb 2015, 19:06

by macmakkara

Im really interested in this one. Im still on my hunt for f62 or f77. But if this will come alive im in for sure!

Posted: 27 Feb 2015, 08:34

by mougrim

Yeah, me too. I'd glad to help, but I'm living in the ass of the world