Page 1 of 1

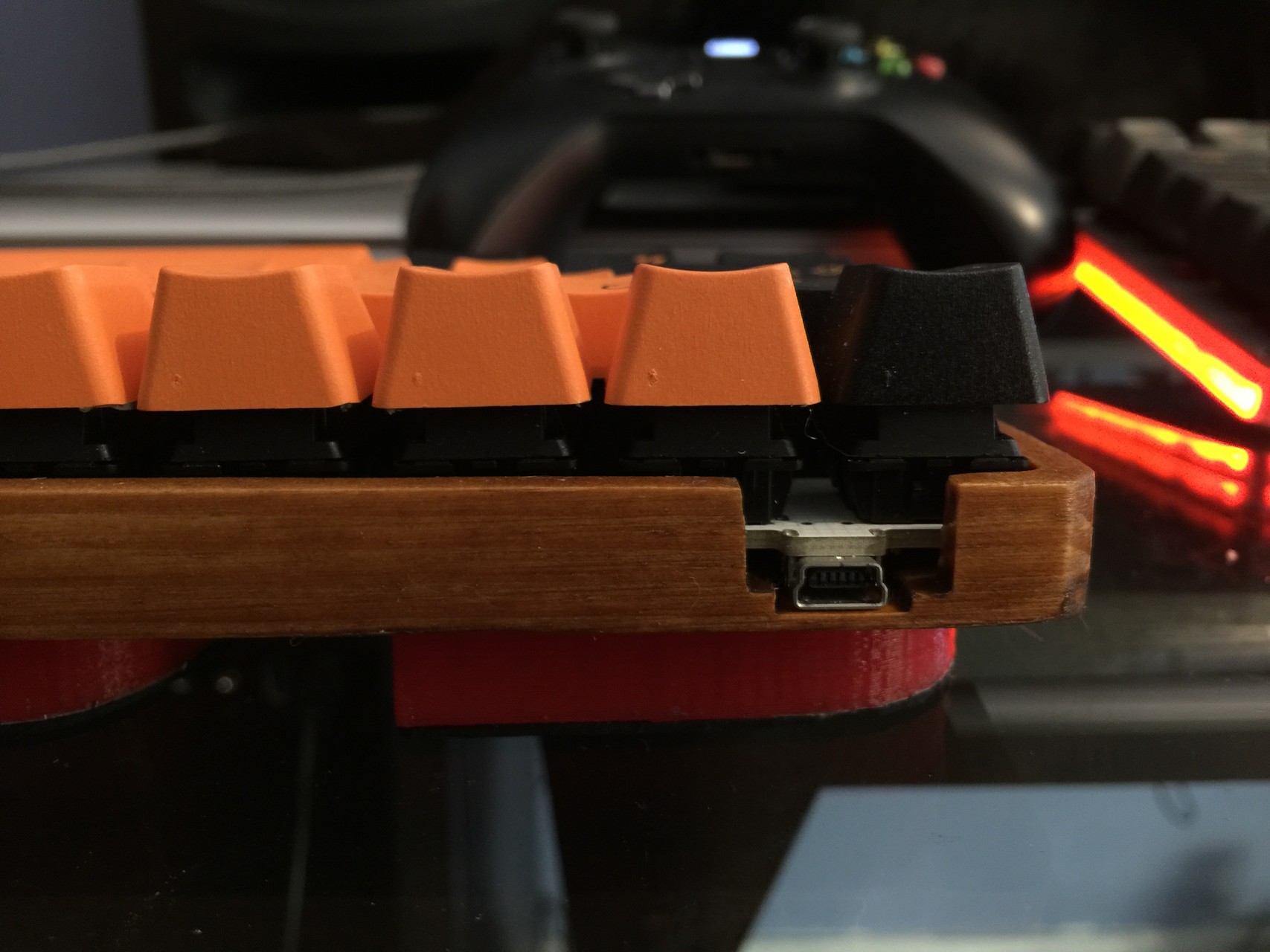

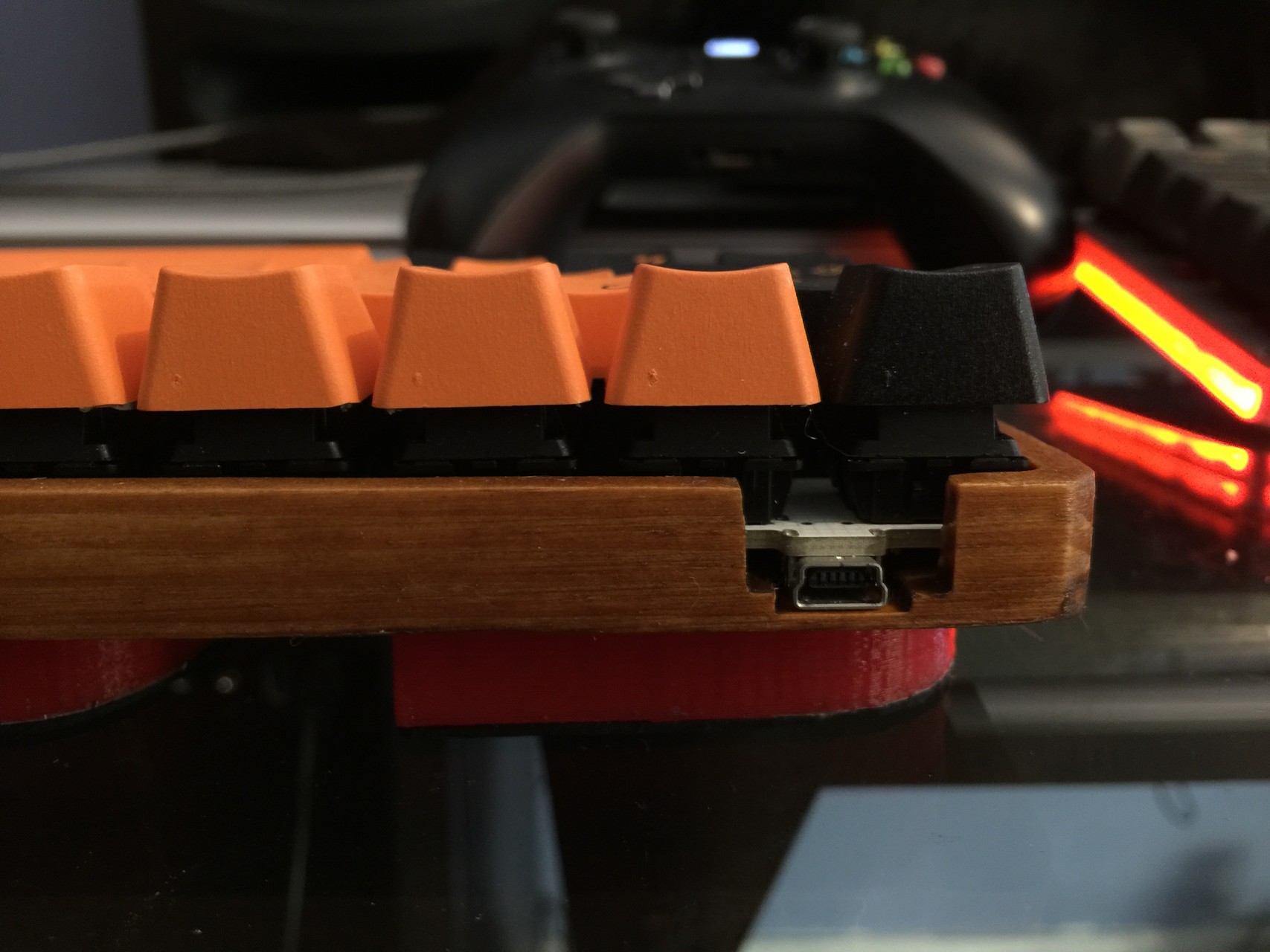

NerD 60 Custom wood case

Posted: 30 Jul 2015, 15:08

by yobinad

Posted: 30 Jul 2015, 15:11

by Muirium

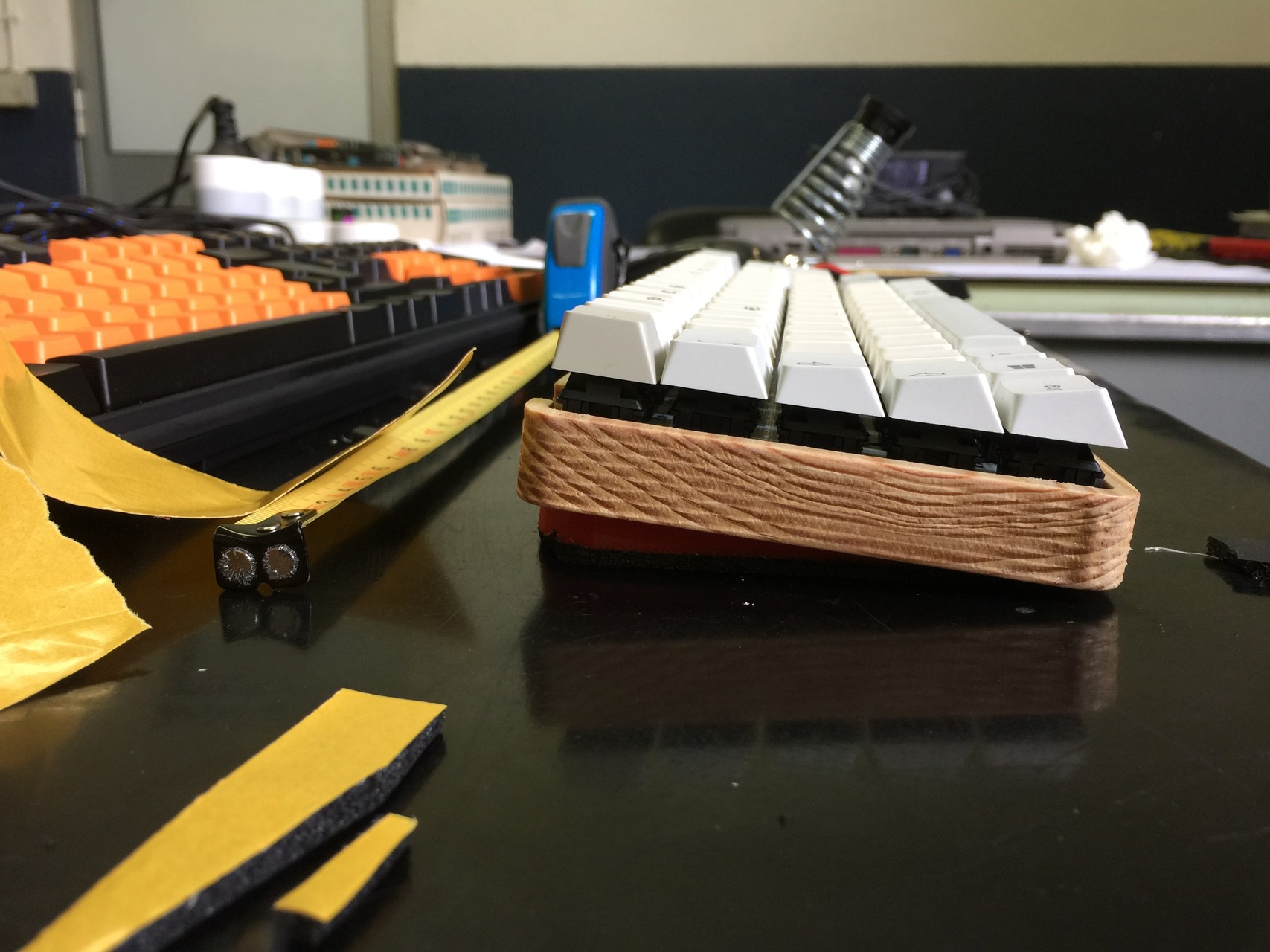

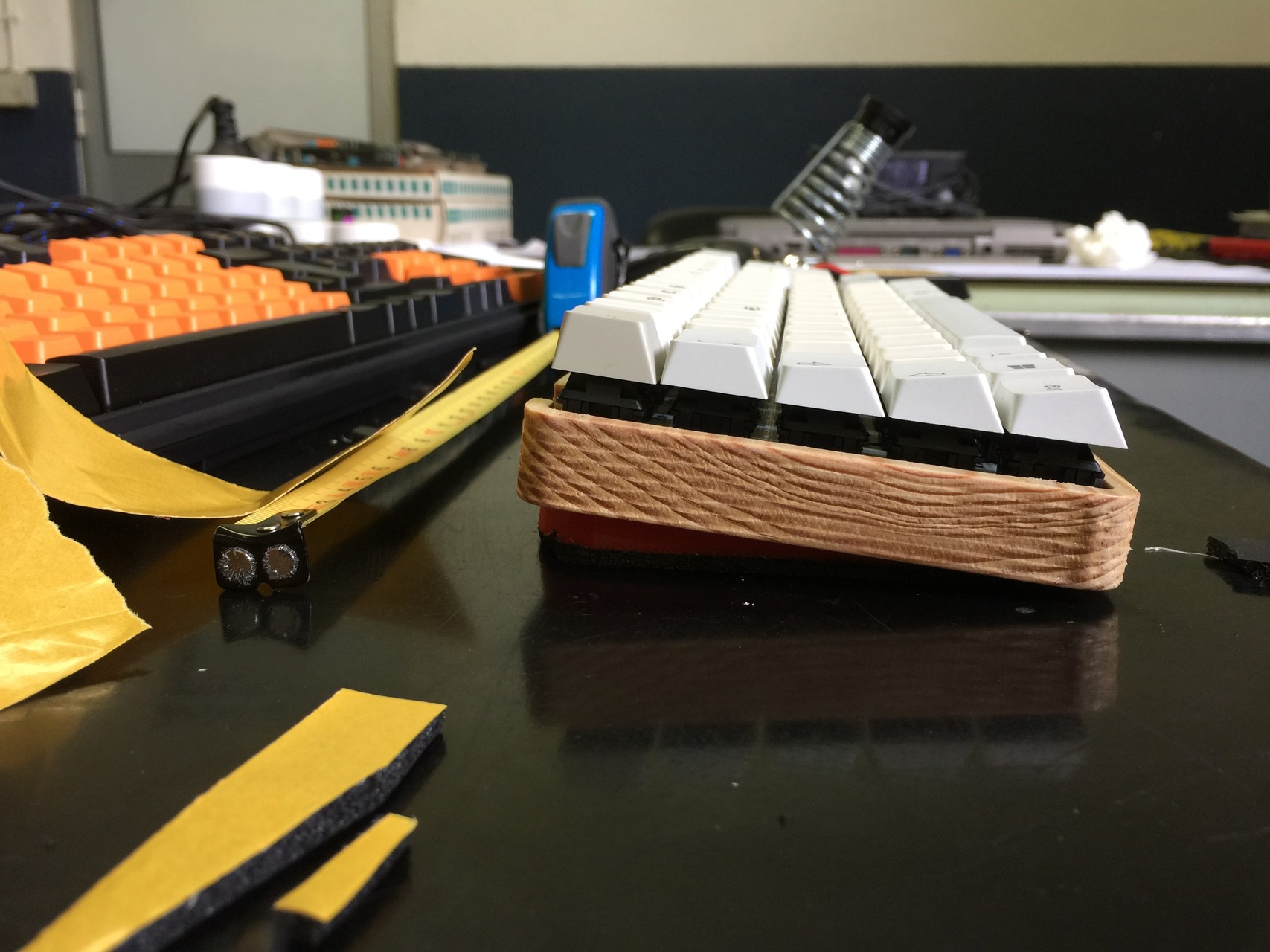

Those feet are glorious! Now I'm trying to imagine an entire case built from type…

Posted: 30 Jul 2015, 15:58

by HzFaq

Nice work. The feet are good, the case is better

.

Posted: 30 Jul 2015, 16:04

by yobinad

The feet was my friends idea. They look really nice without the foam adhesive.

The plastic is very rigid. Without the foam it would be slippery.

There's is another kind of plastic, more rubberized, but my friend doesn't have it. I would not use the foam adhesive with that.

Posted: 30 Jul 2015, 18:01

by pyrelink

That looks fantastic! About the case, I can see that some of the standoffs look as though they were glued down to the base, is that the case with all of them? Was any part of this milled? Any more pictures of the case building process?

Posted: 30 Jul 2015, 18:07

by Madhias

Very nice, I actually like all of it! The feet are something new and are a nice feature. Would you share the files of the case?

Posted: 30 Jul 2015, 19:06

by yobinad

@pyrelink, the case was fully milled. Maybe the varnish makes it look like something is glued.

@Madhias, yes i can share the case file. It is 2D though. My friend likes to do it that way. I'll get the file from him and share it.

Posted: 07 Aug 2015, 00:04

by yobinad

These are the two 2D files used to make the case.

Mind that this was made for ISO. ANSI requires some dremel on pcb support because LEFT SHIFT and ENTER stabs, and because of some in-switch leds on the bottom row.

The desirable depth was defined between gcode lines.

Inside and

outside

Posted: 13 Aug 2015, 01:09

by yobinad

Milled the pcb support 1mm and 3 on the bottom of the case.

Made a short video with me working with a "state of the art machine", milling the bottom of the case.

Posted: 20 Aug 2015, 22:14

by yobinad

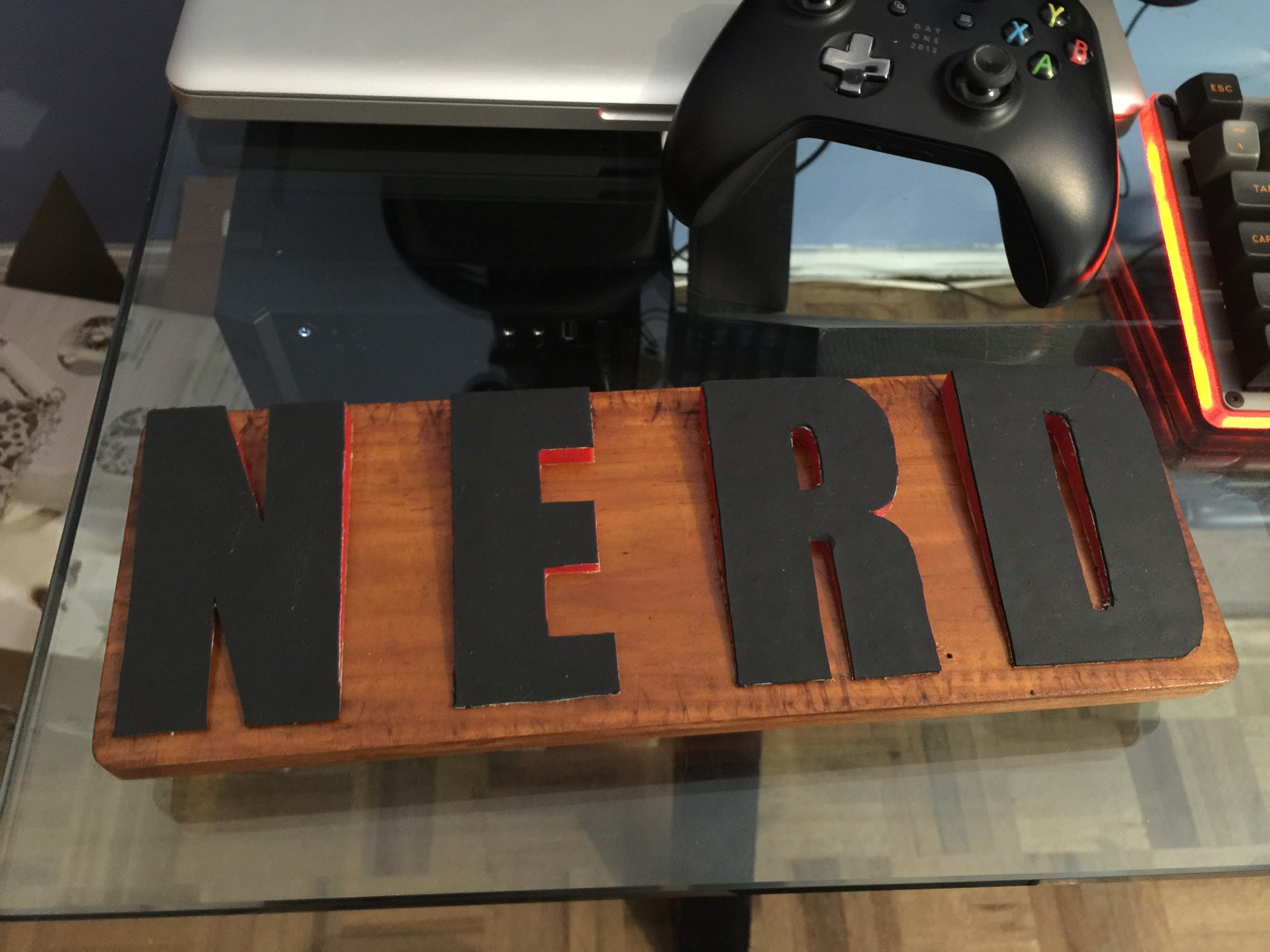

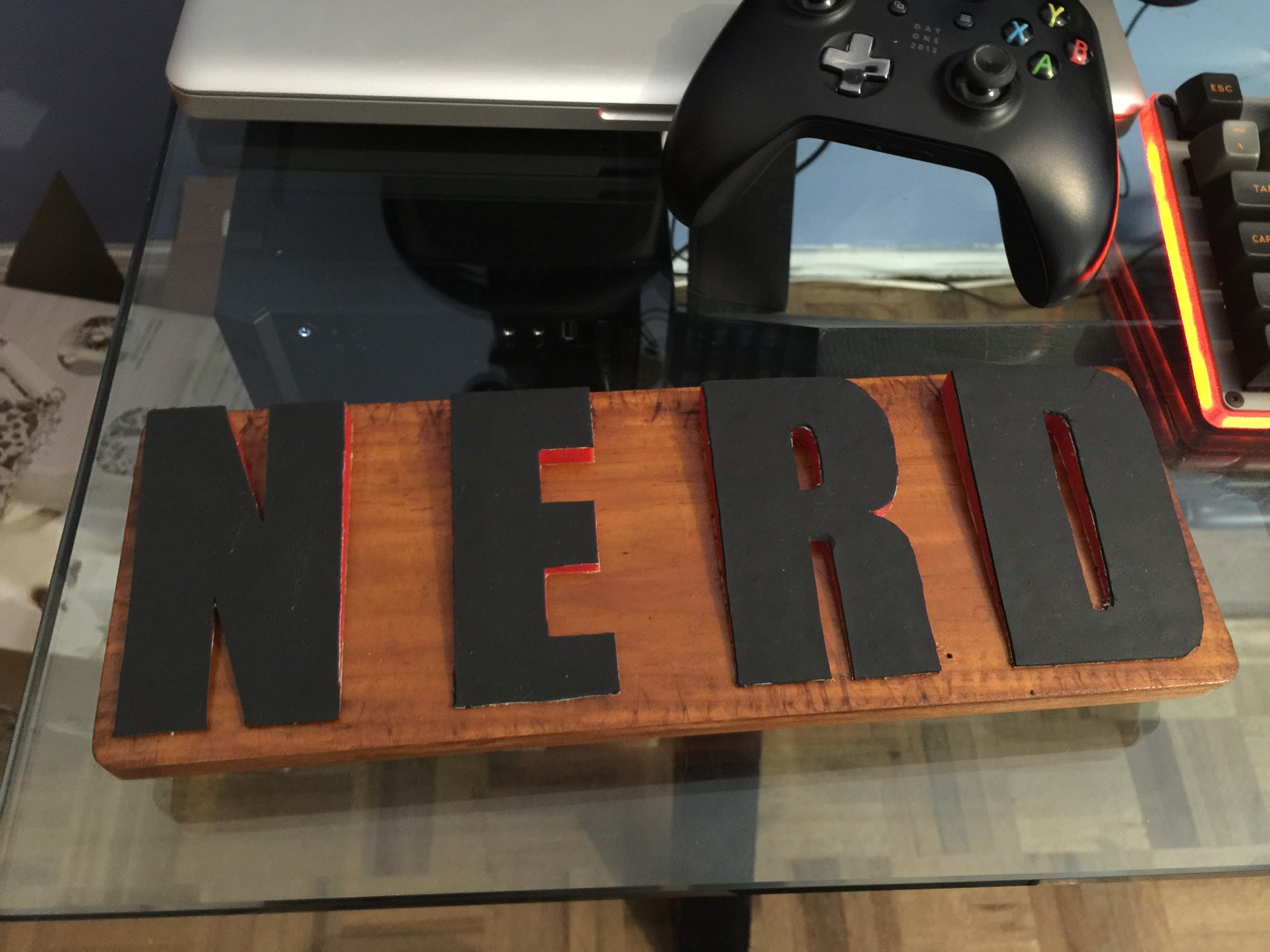

Made some changes in the case.

The switches were 4mm higher than i want. Milled 1mm of pcb support and 3mm at the bottom of the case.

I treated the case with oak stain, two coats.

Glued 1mm rubber to the letters with double sided adhesive tape and glued the letters to the case with double sided adhesive tape as well.

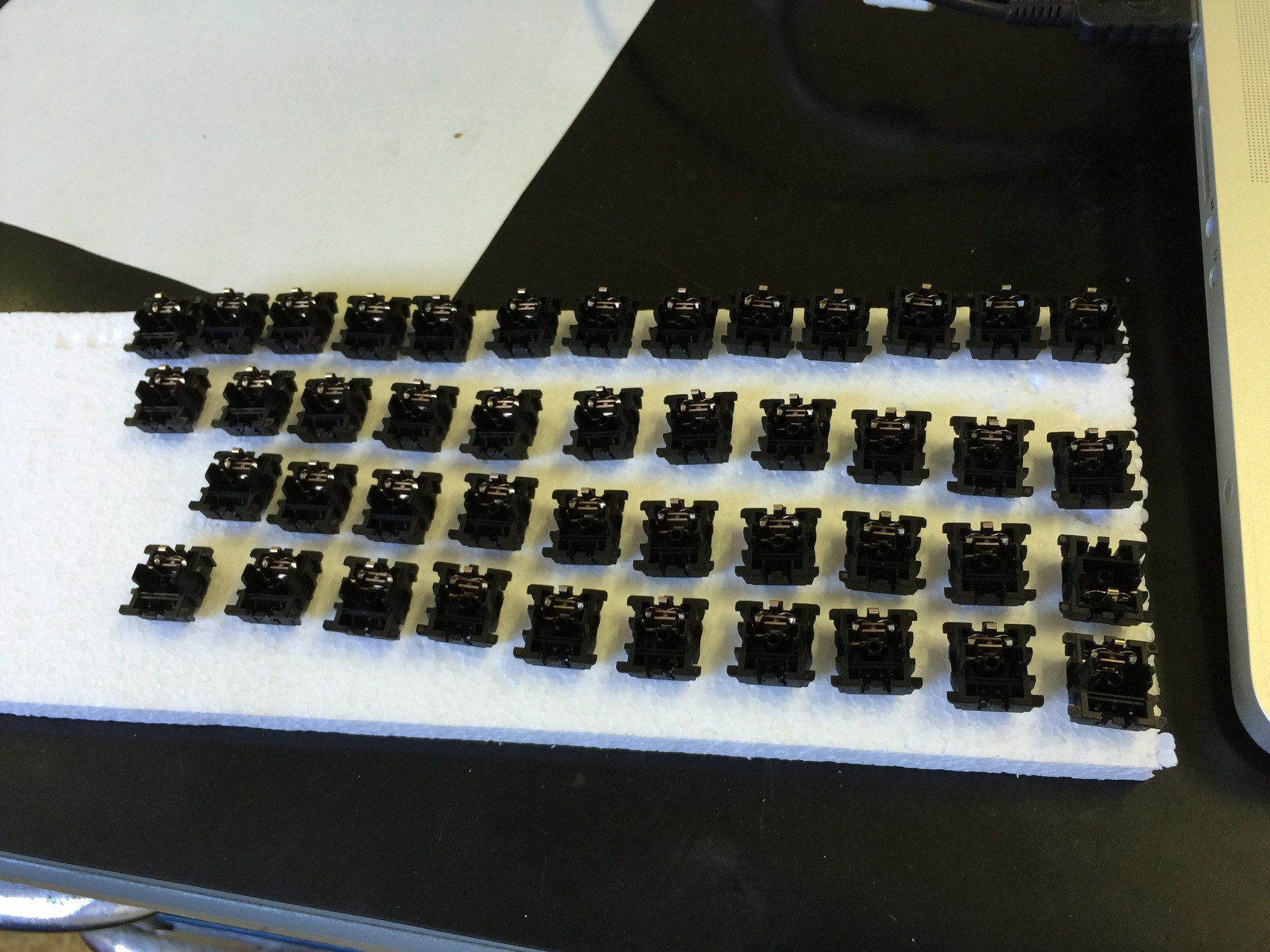

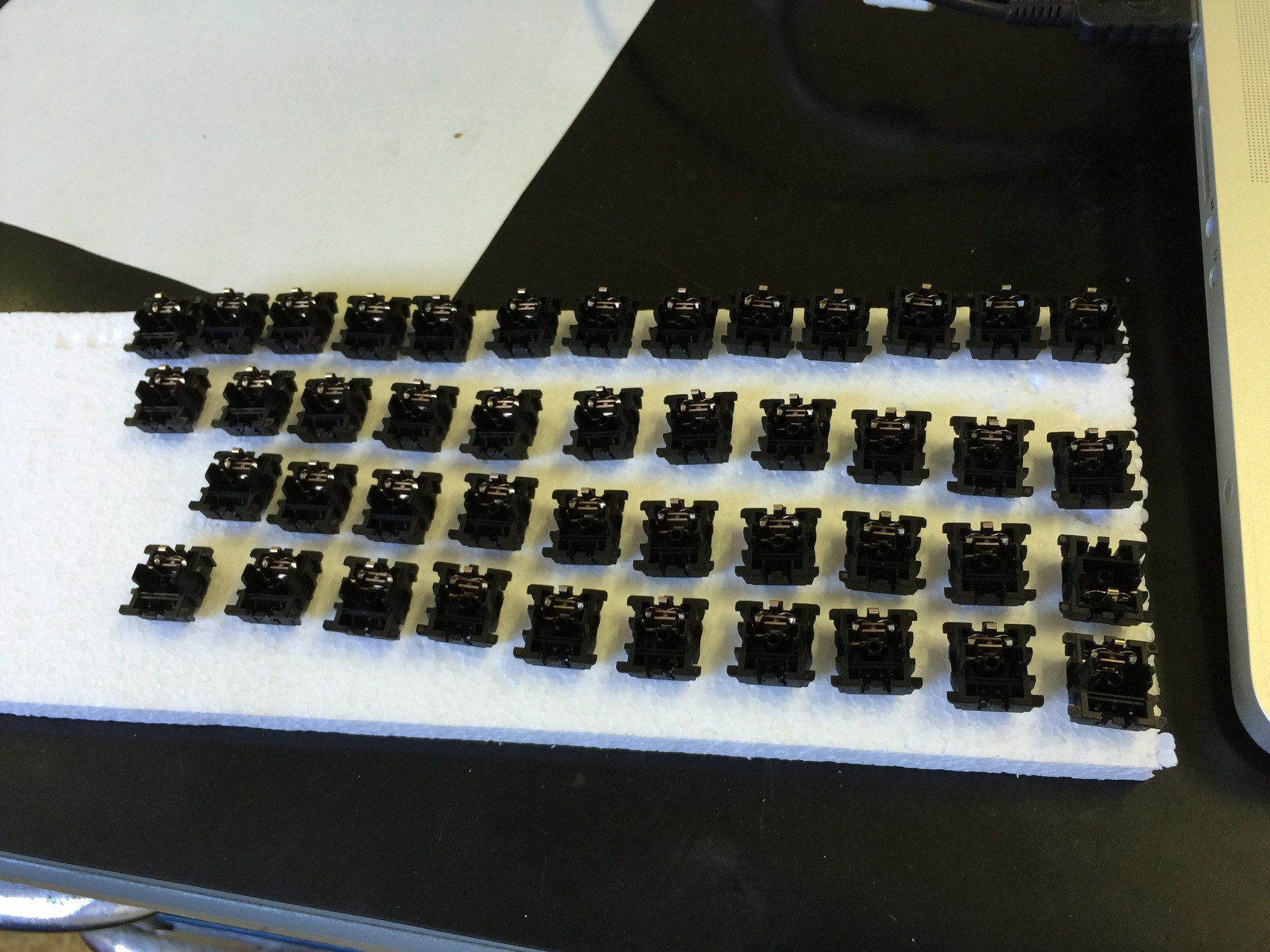

Now i'm waiting for the gateron browns and for the HONEYB/CREAM set to finish it.

Posted: 20 Aug 2015, 22:23

by HAL

yobinad wrote: Milled the pcb support 1mm and 3 on the bottom of the case.

Made a short video with me working with a "state of the art machine", milling the bottom of the case.

Very nice keyboard. And most impressive milling

Posted: 20 Aug 2015, 22:50

by Findecanor

By hand with drill-press? That is impressive.

Posted: 20 Aug 2015, 23:47

by ramnes

I want those feet. Group buy please!