Page 1 of 1

Identify the Keycap

Posted: 02 Nov 2016, 18:35

by Hypersphere

Does anyone here know what kind of printing was used on keycaps from a SIIG Supertouch KB101K with white Alps switches? The keycaps have a nice pumice-like texture. At first, I thought they might have been dye-sub PBT, but I did the acetone test on the inside of a cap, and this indicated ABS rather than PBT. However, the lettering looks like dye-sub to me. I don't have a camera with a macro lens, so I don't think my potato pics would be of much help.

The DT wiki refers to the SIIG Supertouch as a rebranded Chicony KB-5181, but it says that K101 is a SIIG Suntouch rather than a SIIG Supertouch and the SIIG Supertouch is model JK-WJ0032. However, mine is a SIIG Supertouch, but the model number is K101.

The switches look brand new, and they have "ALPS" on the top housing.

Posted: 02 Nov 2016, 18:40

by ohaimark

Photos would help. You might just have some particularly magical lasering that looks good.

Posted: 02 Nov 2016, 19:04

by Hypersphere

Posted: 02 Nov 2016, 19:10

by ohaimark

It looks like rimless pad printing to me. The edges are a wee bit sharp for dye sublimation.

The good news is that rimless pad printing is passably durable.

Posted: 02 Nov 2016, 19:16

by Hypersphere

Thanks! What is "rimless pad printing"?

With respect to touch -- I cannot detect anything raised in the legends. There seems to be a seamless merge of legend and keycap material.

Perhaps related to this -- I have keycaps from a Dell "Old Logo" AT101. These have similar properties to those of the SIIG Supertouch 101K. That is, they feel and look like dye-sub PBT, but the keycap plastic is dissolved by acetone.

Posted: 02 Nov 2016, 19:22

by Chyros

Rimless pad printing or Acer printing (likely UV).

Posted: 02 Nov 2016, 19:30

by ohaimark

Rimless pad printing is extremely thin pad printing with durable ink. I'm guessing they bond it to the substrate using some particularly volatile chemical method. The whole "rimless" thing was termed because you can't feel the edges of the printing. Keycap texture helps hide any hints of edges that might exist.

There are only two ways to tell for sure: macro photography or cutting. The old logo Dell surprises me a bit, but from what I understand the caps and keyboards went through a bunch of phases. Perhaps they produced rimless pad printed keycaps for a limited amount of time during a transition between manufacturers (or something).

Other options include: an ABS dye sublimation process or the use of an acetone-positive plastic compound that could withstand the heat of standard dye sublimation.

I don't think it's Acer style -- the contrast on the legends is too good.

Posted: 02 Nov 2016, 19:38

by XMIT

FWIW, I do have a pretty nice macro lens and good light. Do you have any similar boards - that I might also own - that have these key caps?

You can always mail one over if you're really curious.

Posted: 02 Nov 2016, 19:42

by ohaimark

I'm also equipped, and I'm a wee bit closer.

Edit: for some reason the wiki photos didn't link right.

You can find my profile photo and a few other shots I took here.

wiki/Keycap_printing

Posted: 02 Nov 2016, 19:52

by Chyros

Hypersphere wrote: Thanks! What is "rimless pad printing"?

It's a term I coined to differentiate two different kinds of pad printing. Traditional pad printing involves basically a sticker with visible edges of a clear coating, while rimless printing doesn't use a sticker like that and therefore doesn't have these edges. The difference is quite noticeable up close.

Posted: 02 Nov 2016, 20:00

by Hypersphere

My Old Logo Dell AT101 set is from a model with S/N GYUM97SK. The caps are so nice that I put them on my refurbished Northgate Omnikey 101. I like the appearance of the Northgate doubleshots, but the Dell caps have a texture like fine pumice, similar to some of the Chinese PBT caps. However, the Dell caps dissolve in acetone. The test I use is to moisten a cotton swab with acetone and rub the swab on the inside of a cap. If the swab leaves permanent marks in the plastic, I assume it is ABS (or at least that it is not PBT).

BTW, all the doubleshot sets that I have seen from Northgate Omnikey 101 boards thus far (five of them) have been very white, i.e., very little yellowing. Did they use a different ABS formulation from that of other keyboard in the same era? Perhaps lacking brominated flame retardants? Or maybe their owners liked to type in the dark.

Another BTW -- the Supertouch is a nice board. If only it were complete US ANSI instead of BAE.

Posted: 02 Nov 2016, 20:20

by Hypersphere

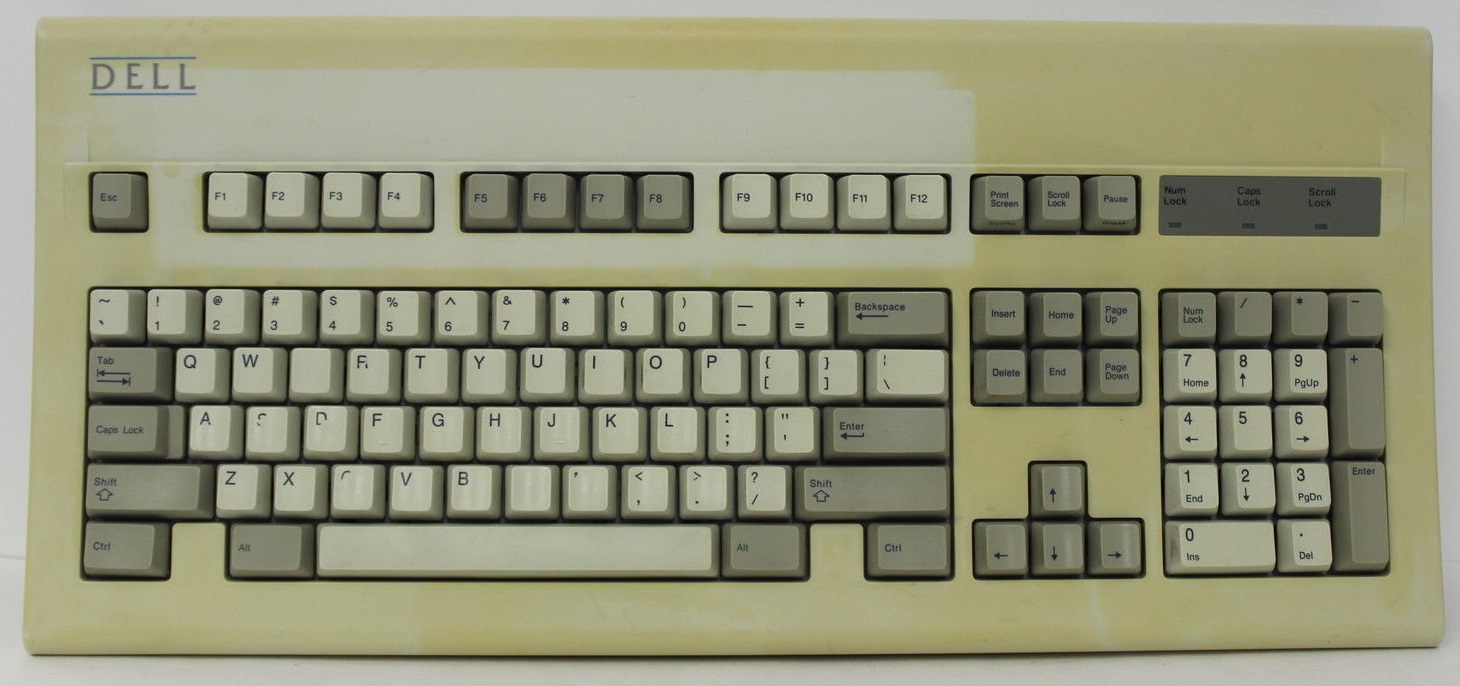

Looks like the printing on at least some Old Logo Dell AT101 GYUM97SK boards is not all that durable:

- dell_old_logo1.jpg (218.87 KiB) Viewed 4398 times

http://www.ebay.com/itm/DELL-25109-PS-2 ... 2174694245

Maybe I should put the doubleshots back on the Northgate, although they are rather shiny. I've been tempted to use an SGI Granite set, but I can't get past the Italic font.

Posted: 02 Nov 2016, 20:22

by ohaimark

Yep, the verdict on your old Dell is rimless pad printing.

Posted: 02 Nov 2016, 20:42

by Hypersphere

Yikes! Maybe I should remove the pad-printed caps from my Omni 101, even if the printing is rimless, although I wonder how long it would take to start noticing wear of the legends?

Posted: 02 Nov 2016, 20:58

by Chyros

Hypersphere wrote: Yikes! Maybe I should remove the pad-printed caps from my Omni 101, even if the printing is rimless, although I wonder how long it would take to start noticing wear of the legends?

It's usually fairly resilient, I wouldn't worry too much about it. Why did you stick pad-printed caps on your OmniKey though? Oo

Posted: 02 Nov 2016, 21:41

by XMIT

You can always de-shine double shots using a Scotch Brite pad.

Posted: 02 Nov 2016, 21:53

by Hypersphere

Chyros wrote: Hypersphere wrote: Yikes! Maybe I should remove the pad-printed caps from my Omni 101, even if the printing is rimless, although I wonder how long it would take to start noticing wear of the legends?

It's usually fairly resilient, I wouldn't worry too much about it. Why did you stick pad-printed caps on your OmniKey though? Oo

The stock doubleshots on the Omni are very handsome and they have not appreciably yellowed. However, they are rather shiny, and I prefer the feel of PBT.

Initially, I swapped the stock alphas with dye-sub PBT caps from an IBM 5140 -- these caps work very well on my V60 with Matias Clicks and on my DC-3014 with blue Alps, but on the Omni, they did not bottom out consistently. Why would this be? I check to ensure that the caps were completely seated on their stems, but I still got this inconsistency in bottoming out. Strange.

While rummaging through my keycap sets, I found a set from an old logo Dell AT101 that looked and felt to me like dye-sub PBT and so I put them on the Omni 101. Now I realize that the Dell caps are rimless pad-printed ABS. Even if these are fairly durable, I would prefer knowing that I had dye-sub PBT caps on the Omni 101.

I have a dye-sub PBT set from an IBM P70, but these are eggshell thin with a rather heavy font. I also have a dye-sub PBT set from an SGI Granite, but these have an Italic font that I don't particularly like.

EDIT: I have a dye-sub PBT set from a Wang 725-3770, but the profile is just slightly lower than whatever is "standard" (such as the ABS blanks from Matias that I use for mods). Likewise, I have dye-sub PBT caps from AEK boards -- these are of high build quality but definitely not standard.

Posted: 02 Nov 2016, 21:57

by Hypersphere

XMIT wrote: You can always de-shine double shots using a Scotch Brite pad.

This would have never occurred to me. Do you happen to have any close-up before and after pics of caps "de-shined" this way? Exactly which Scotch Brite product did you use? Do de-shined caps re-shine at the same rate as new caps develop shine? Or, to paraphrase the woodchuck ditty, How much shine would a de-shine shine if I de-shine could re-shine?

Posted: 02 Nov 2016, 22:17

by Chyros

Hypersphere wrote: XMIT wrote: You can always de-shine double shots using a Scotch Brite pad.

This would have never occurred to me. Do you happen to have any close-up before and after pics of caps "de-shined" this way? Exactly which Scotch Brite product did you use? Do de-shined caps re-shine at the same rate as new caps develop shine? Or, to paraphrase the woodchuck ditty, How much shine would a de-shine shine if I de-shine could re-shine?

You can also sandblast them, it works very well. Someone here can do it for you.

Posted: 02 Nov 2016, 23:28

by Hypersphere

Sandblasting!

Before:

- sb_before.jpg (25.15 KiB) Viewed 4341 times

In process:

- sandblasting3.jpg (45.05 KiB) Viewed 4341 times

After:

- sb_after3.jpg (17.37 KiB) Viewed 4341 times

Seriously, at first I thought you were in jest, but then I found that people really do sandblast their keycaps! Nevertheless, I think I will seek other solutions first. Interesting idea, though!