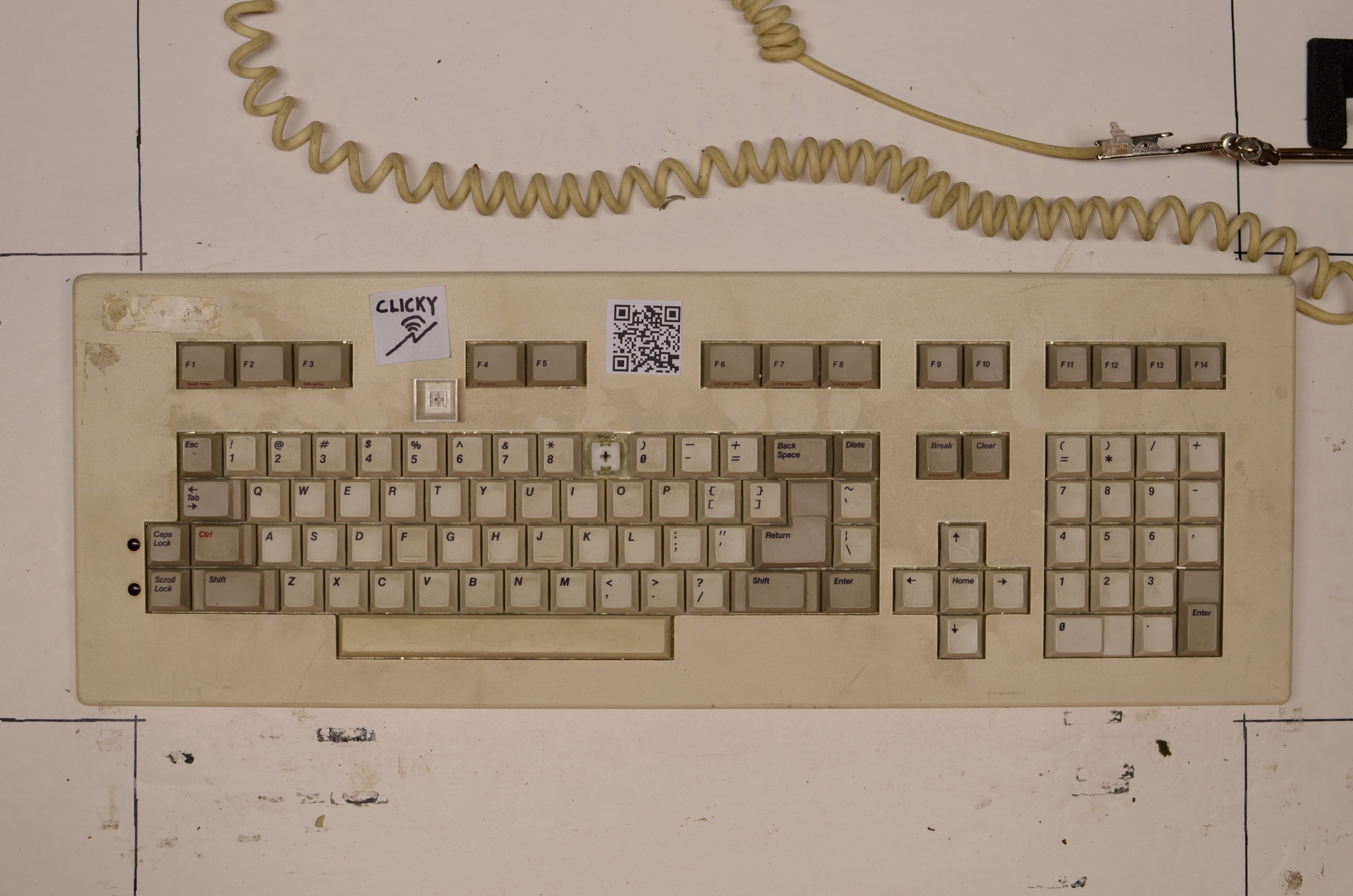

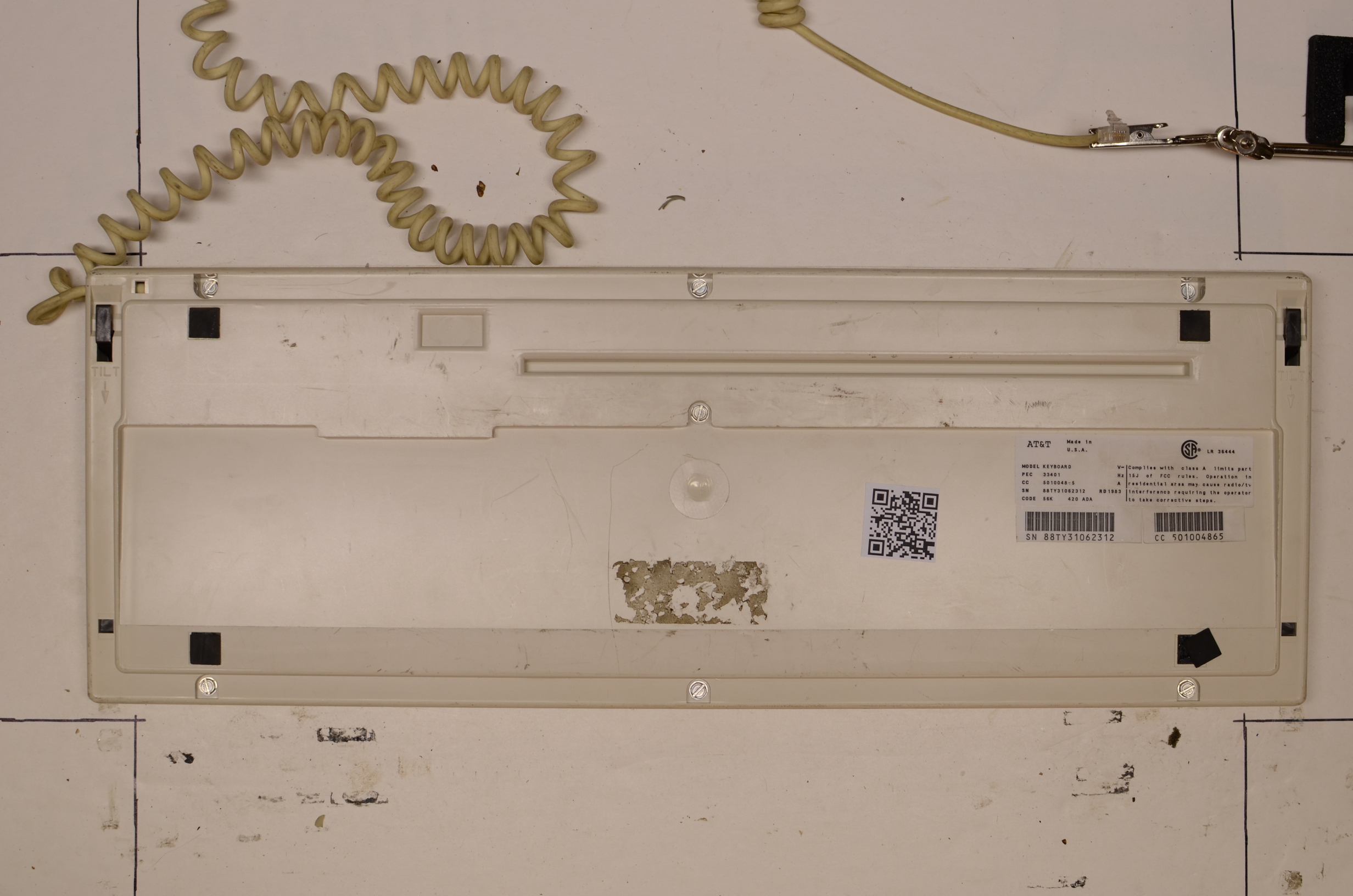

AT&T Magnetic separation, clicky, foam and foil

Posted: 27 Jul 2018, 06:22

I recently met a man named Aaron who had discovered a cache of terminals from the 1980's. More on that to come. Among them were a few made by the Teletype Corporation subsidiary of AT&T. This terminal used 122 key style keyboard that I had not seen before. At first glance I wasn't expecting anything exciting but on closer inspection, the switch mechanism turned out to be quite interesting.

The keyboard uses a foam and foil switch that is truly clicky and quite tactile. Both the click and tactility is provided by the separation of a metal collar on the slider from a magnet retained by the switch housing. The resulting feel has sharp tactility, very unexpected for a foam and foil switch.

The keyboard is documented in the wiki AT&T Teletype 56K 460 ACW

Here is a video of the switch: The keycap attaches to a plunger that presses on a spring. The spring presses on the slider which has a ferrous collar. The ferrous collar is attracted to a magnet retained by the switch housing. When the keycap is pressed, the spring compresses and force on the slider increases until it exceeds the attraction between the magnet in the housing and the collar on the slider. The slider then breaks free and releases the spring tension which forces the foam and foil pad in contact with the PCB.

Here are few pictures of the switch and mechanism:

The keyboard uses a foam and foil switch that is truly clicky and quite tactile. Both the click and tactility is provided by the separation of a metal collar on the slider from a magnet retained by the switch housing. The resulting feel has sharp tactility, very unexpected for a foam and foil switch.

The keyboard is documented in the wiki AT&T Teletype 56K 460 ACW

Here is a video of the switch: The keycap attaches to a plunger that presses on a spring. The spring presses on the slider which has a ferrous collar. The ferrous collar is attracted to a magnet retained by the switch housing. When the keycap is pressed, the spring compresses and force on the slider increases until it exceeds the attraction between the magnet in the housing and the collar on the slider. The slider then breaks free and releases the spring tension which forces the foam and foil pad in contact with the PCB.

Here are few pictures of the switch and mechanism: