Page 1 of 1

thick PBT, do-it-yourself?

Posted: 09 Jul 2014, 09:43

by Eszett

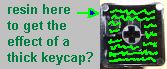

Thick PBT keycaps are highly requested, and I thought about how man could be possible to turn thin keycaps into thick ones. We could lacquer them, but the lacquer coat is rather a drop in the bucket, the keycap will not be substantially thicker afterwards. The lacquer coat changes the appearance too, not alway to the best result. What if resin is poured into the inner side of the keycap, in the hollow cave between the mount and the rim? Look at the sketch

- images.jpg (5.58 KiB) Viewed 8195 times

That would increase the keycaps weight and thickness and

perhaps could(?) result in the same effect, that a truely thick keycap has, a lower sound and more massive tactile sensation when typing. What do you think?

pro: doesn’t affect the appearance

cons: not undo-able

Posted: 09 Jul 2014, 09:47

by matt3o

I actually did this. (should have a picture somewhere...). the end result was just meh. The resin "vetrifies" and has a very different texture compared to PBT.

You can't add too much resin otherwise the cap hits the switch too early. Also you can't make the sides thicker.

Posted: 09 Jul 2014, 09:51

by Eszett

@matt3o Oh, what a pity

I guess it is difficult to understand the physical reason that lead to an enjoyable typing sensation and the physical reasons resulting in a “meh” typing sensation, as you call it.

Posted: 09 Jul 2014, 09:55

by matt3o

actually, it might work with clay... have to try (and it's undoable)

Posted: 09 Jul 2014, 10:30

by Eszett

Clay!? do you mean fired or unfired clay? Isn’t unfired clay of similar consistence as plasticine?

Posted: 09 Jul 2014, 10:37

by matt3o

yeah, plastiline. it's pretty hard when cold.

Posted: 09 Jul 2014, 11:11

by Eszett

Ah, you mean la plastilina, the children’s toy. I would be glad to read your typing impressions!

- flair-plasticine-activity-bucket.jpg (12.95 KiB) Viewed 8153 times

Posted: 09 Jul 2014, 13:13

by Grond

I think whatever material you use, you'll just end up adding weight to the keycap, but you don't really make it more solid.

Posted: 09 Jul 2014, 13:23

by shreebles

Unfired clay will dry out however and start to crumble... I think it's safe to say we do not want pieces of dried clay inside our keyboard switches

Hot glue perhaps? Not undoable but cheap and dosage should be easy... Plus it would assume whatever shape your keycaps have so it should be pretty solid.

Posted: 09 Jul 2014, 15:06

by Muirium

This seems like a pretty terrible idea, all round. Thickness alone doesn't count for anything. It's the base material itself that makes the difference. You'd be better off casting your own caps if you like to get messy!

Posted: 09 Jul 2014, 18:09

by Kurk

Or fill it with heat-curing plastic clay. In Germany, the brand "Fimo" is popular. It can be hardened at 110 °C which is a temperature that PBT caps should be able to withstand (space bars could warp though).

http://en.wikipedia.org/wiki/Fimo

Posted: 09 Jul 2014, 18:09

by Findecanor

I think that some guys on an Asian forum tried some kind of polymer-clay (Sculpey, Cernit, Fimo, ...) They cure at about 130° C, which is too hot for ABS but not too hot for PBT.

However, polymer clay is only sticky until it cures.. so it is stuck in the keycap by friction alone.

Posted: 09 Jul 2014, 21:08

by Eszett

Hm, interesting this Fimo. At such a high temperature I would not cure it together with the caps. How about curing it without the caps: fill the caps with Fimo, remove it from the caps, then cure it. Then it is conform and you can glue it to the inside of the cap and it fits perfectly?

Posted: 10 Jul 2014, 01:07

by shreebles

I doubt it would stick unless you glue it in there... Once the Fimo has hardened out, it is no longer sticky.

Posted: 10 Jul 2014, 01:24

by Findecanor

You could also use epoxy clay, such as Milliput.

But what is the point of making it thicker? Weight? Rigidity?

Posted: 10 Jul 2014, 07:55

by matt3o

epoxy clay is too hard (even harder than resin). I believe the perfect filling should be slightly softy.

Posted: 10 Jul 2014, 13:01

by Eszett

Findecanor wrote: But what is the point of making it thicker? Weight? Rigidity?

The point of making it thicker is to improve the typing sensation, because thin plastic feels cheap due to high-pitched sound and vibration.

Posted: 10 Jul 2014, 22:13

by Findecanor

matt3o wrote: epoxy clay is too hard (even harder than resin). I believe the perfect filling should be slightly softy.

I sometimes mix my own epoxy putty, out of epoxy adhesive and various filling powders such as colloidal silica, microballoons and talcum powder, but I have never succeeded in making a mix that would be good enough as modelling clay.

Posted: 23 Feb 2016, 11:05

by Wodan

Try wax bros. I've been using wax to improve the feeling of cheap 60% plastic cases, just melt a few candles and pour the liquid wax into them. Just make sure they are leveled and the wax can form a nice surface before it hardens.

Probably wise to add some o-rings afterwards to make sure the wax keeps a little distance from the switch !

Posted: 23 Feb 2016, 11:51

by tentator

I like wax as an idea..

What about vinavil glue maybe??