Page 1 of 1

Teensy Desoldering Technique

Posted: 06 Feb 2015, 12:14

by Muirium

Anyone got advice how to desolder a Teensy (in this case) which is installed with legs in a PCB? I'm looking to harvest one from a prototype PCB I don't use any more, and tried in vain to suck all the solder out of it and pull it off. Just the tiniest bit of solder on each leg seems to be needed to keep it stuck fast!

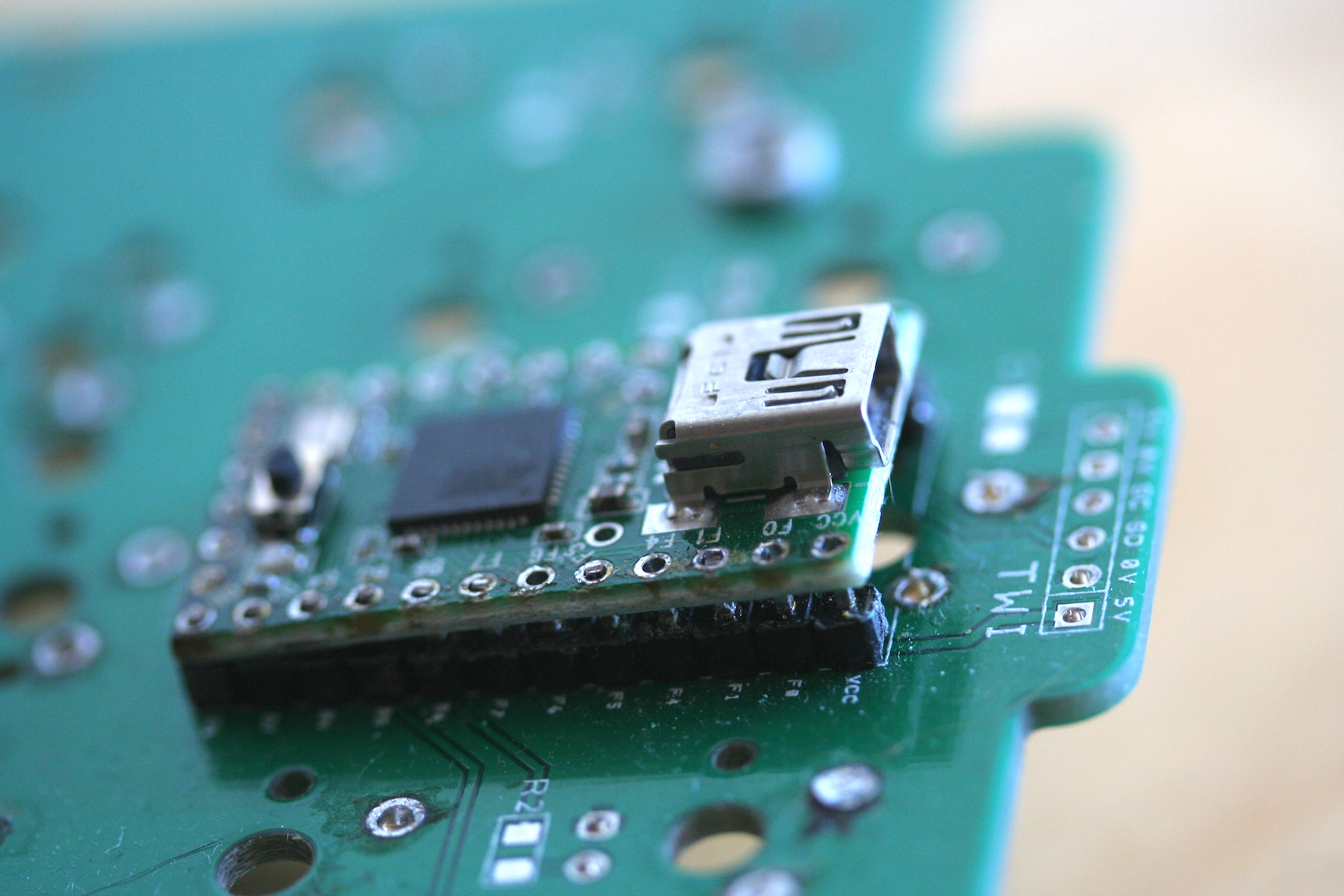

- IMG_7253.JPG (1.03 MiB) Viewed 9468 times

As you can see, I've already been quite beastly with it! I tried desoldering the pins from the top and the bottom, naturally. Nothing much still comes out, and I'm quite stuck.

I'm guessing I need to be able to melt multiple pins worth of solder simultaneously, with specialised gear?

Posted: 06 Feb 2015, 12:20

by HzFaq

Blowtorch? I guess try a pass with a solder sucker and then try to get the remainder up with some wick/braid or something maybe.

Honestly, I've tried and never been able to do it with just an iron as like you've said, the tiniest (teensiest?) bit of solder on a leg keeps it in place. I guess with some kind of hot air gun/smd gear you might be able to heat all the legs long enough to yank it out but I've not got the gear to try.

Posted: 06 Feb 2015, 12:27

by idollar

Option 1 - no specialized device

If you have enough gap under the teensy board, insert a long rigid item (I use the same latte macchiato spoon that I use to remove IBM keycaps) and apply upward pressure to a side only (twist the spoon). Apply heat to each pin in sequence. Each loop will bring the teensy up a little bit until the side is free.

Option 2 - desoldering

Cheap pump -

http://www.ebay.de/itm/EP-595-Desolderi ... 4d2bf1c5bd

Expensive one -

http://www.ebay.de/itm/ATTEN-AT-858D-22 ... 19e81e619e

Re: Teensy Desoldering Technique

Posted: 06 Feb 2015, 13:28

by chzel

If the pcb is sacrificial, heat one pin at a time, teensy side, and try to push the pin through to the bottom.

Posted: 06 Feb 2015, 13:41

by Muirium

I've heated the Teensy enough to scorch it a few places, as the photo exposes! I'm not sure what I'd have to do to push the pins through. Heat and force? Trouble is, my soldering iron is too blunt to go through the holes.

@i$: You bet I've been using a suction pump. Like HzFaq says, the slightest bit of cool solder residue and those pins stay stuck hard! I was essentially trying your other technique as well, levering and heating. But there's too many damn pins to let me lever while just heating one at a time. The Teensy's still stuck hard down at the back end, where most the pins are.

I should mention there's an MX black on the underside of this PCB (really the Teensy is slung underneath) which is stuck in as well, hidden by the Teensy, which makes leverage tricky.

Posted: 06 Feb 2015, 13:44

by vvp

Hot air would be a good option if you would not need to keep the components on teensy intact. Still it should be doable with hot air, you are very careful.

The other easy option is using a pistol iron with a specially shaped wire loop. Bend the wire loop so that it touches all the pins of your teensy. Activate the iron outside the teensy. touch the wire loop to teensy pins. When the tin melts pull out the teensy with the iron still on it. Remove iron loop from teensy, deactivate iron.

You will need to tin the teensy legs again so that the heat from the loop transfers to the teensy.

Here is a video how one tries to do the same without a pistol iron. A bit more complicated but you will get the idea.

https://www.youtube.com/watch?v=gSzfNrbDfIY

Posted: 06 Feb 2015, 13:50

by vvp

There is one more option. And this may be easier for you but it is more destructive.

Take a dremel with a cutting wheel. Cut the pins connecting teensy to pcb. then remove the pins one by one.

Re: Teensy Desoldering Technique

Posted: 06 Feb 2015, 14:24

by hasu

I'd use chipquik

EDIT: SMD removal kit will work. It is low temp solder in the end.

Posted: 06 Feb 2015, 14:54

by cookie

I watched a chipquick video on YT, actually really interesting! But I think that a desoldering pump would be good, It never failed me

Posted: 06 Feb 2015, 15:06

by beltet

When i'm desoldering im using a suction pump. I will try to descripe how I do.

1. Apply a little extra solder to the joint if the joint has little solder.

2. With a well heated soldering iron(recommend soldering station) you put the tip on the joint till it bubble a little bit.

3. Remove the solder tip and in the same time put the suction pump over the joint and release it.(you have to be very fast)

4. Not free? apply solder again and retry.

This techniqe needs some experience. Try this on something thats not valuable if you would heat to much and break things.

I have succesfully done this on my FaceU Replica quite many times. It can be quite hard when there is small distance between the joints, like on the teensy.

Hope this helps.

Posted: 06 Feb 2015, 18:03

by Muirium

Thanks Beltet, I'm probably doing it wrong. I've just been sucking the stuff out, without priming it with new solder. Counterintuitive, but I'll try it!

The Chipquik stuff looks interesting, if a bit expensive for rescuing a single Teensy!

Posted: 06 Feb 2015, 18:07

by photekq

I managed it on a Phantom but I really can't remember how. I think I ended up heating up each pin until the solder melted on both sides, then i pushed out the pin with tweezers. I think.

All I remember for sure is that it wasn't easy.

Posted: 06 Feb 2015, 18:15

by matt3o

it very hard without specialized hardware. I had some success with a huge (de)soldering iron. The tip basically takes the whole row of pins.

Posted: 06 Feb 2015, 19:19

by cookie

@Mu do you have this desoldering pump? If so I am wondering how you struggle to desolder a teensy, the pins are quite nice to reach. If you have a soldering station, try to increase the temperature a bit. The tin-solder has to be hot and liquid so that you can soak it up propperly like beltet describet it.

Posted: 06 Feb 2015, 19:25

by photekq

cookie wrote: @Mu do you have this desoldering pump? If so I am wondering how you struggle to desolder a teensy, the pins are quite nice to reach. If you have a soldering station, try to increase the temperature a bit. The tin-solder has to be hot and liquid so that you can soak it up propperly like beltet describet it.

It's because the holes are small. There is always a little bit of solder left holding it onto the pins. It's really very hard, even with a good pump.

Posted: 06 Feb 2015, 19:28

by Muirium

Yup. I've got a solder station, and I've bubbled that stuff like a volcano in the past, on this specific job. Tricky!

Posted: 06 Feb 2015, 19:43

by cookie

Well, I had a similar situation a few weeks ago. I desoldered a microswitch out of a Razer Deathadder and it was a pain. Putting some fresh tin on the spot helped a lot.

Posted: 07 Feb 2015, 01:02

by beltet

photekq wrote:

It's because the holes are small. There is always a little bit of solder left holding it onto the pins. It's really very hard, even with a good pump.

Thats the hardest part in my opinion to. Its much easier on switches because the holes are bigger and theres nothing nearby thats interfering with your attempt to get the suction pump over the joint.

cookie wrote: @Mu do you have this desoldering pump? If so I am wondering how you struggle to desolder a teensy, the pins are quite nice to reach. If you have a soldering station,

try to increase the temperature a bit. The tin-solder has to be hot and liquid so that you can soak it up propperly like beltet describet it.

one of the main things, it has to be real hot and you need to be a little quick, thats why I recommend to try on something not valuable first.

Posted: 20 Feb 2015, 15:59

by phosphorglow

Did you ever get the little bugger off? I remembered this thread after I just desoldered one from another board.

Posted: 20 Feb 2015, 16:01

by cookie

Jeah that would interest me too!

Posted: 20 Feb 2015, 16:03

by Muirium

Oh, right, I was desoldering a Teensy. The things you remember thanks to the internet…

Not yet. I'll get on it next, after I've installed Cookie's new Topre dampers.

Posted: 20 Feb 2015, 16:15

by phosphorglow

Well, here's my two cents. I'm used to desoldering IC's which are a bit easier because the pins are smaller. Here the tricky part is the solid header pins.

First thing first, flux is your friend.

Take a good sturdy metal pick and carefully go one by one trying to wiggle the pins. If you can't wiggle it, resolder it. My favorite go-to tip is the chisel tip, and my station is set at about 360C. Heat the joint for a good 3-4 seconds and quickly hit it with your solder sucker. Wiggle it again with the pick and move along to the next. Once everything is doing the wiggle, I used a small nylon pry bar to set the little guy free.

I didn't do this, but you might need to: get some solder wick nice and fluxed and go over the pins, and wiggle 'em again with the pick.

Posted: 20 Feb 2015, 16:20

by Muirium

I've got a reel of desoldering wick (Soldasip) but what is this flux of which you speak? I'm aware of it, vaguely, but never used the stuff. Suggestions?

Posted: 20 Feb 2015, 16:41

by phosphorglow

This is the stuff I use. Having some good flux will make your life way easier in many aspects.

Posted: 25 Feb 2015, 11:44

by HzFaq

I finally got around to testing my

hilariously oversized, footlong desoldering pump to remove some teensy pins from a PCB. I'm not sure it would work if you were directly soldering a teensy to a board, but it certainly got the pins out from the PCB nicely.

Posted: 25 Feb 2015, 11:59

by Muirium

Reckon you could do that job with access restricted to just one end of the pins? That's basically what I've got, with the Teensy on top!

Posted: 25 Feb 2015, 12:18

by HzFaq

Hmmm...not sure, if you want to send it over I could have a go. I don't want to make any promises though, I've only done it successfully once....

Posted: 25 Feb 2015, 12:35

by Muirium

I'll give it another go (it's on my list…) especially if I can pick up good flux like Phosphor suggests. Then you're my backup!

Fortunately, I've several Teensies at the moment so it's no rush. But one day that fella's got more work to do! They always do.

Posted: 25 Feb 2015, 12:45

by HzFaq

I practiced/warmed up by desoldering a ribbon cable from an old Cherry board (the one that connected the main PCB to the daughter board). The pin spacing is exactly the same as the teensy, I ended up recycling part of the ribbon cable to hook up the teensy to the new PCB.

I know that not everyone has as many donor boards laying around as I do though so that might not be an option...

I think the crazy oversized pump was the difference this time though as I'm pretty sure I didn't do anything wildly different to the last time I tired with a desoldering pump.