IBM Model F 62 and F 107 Mod Ideas

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

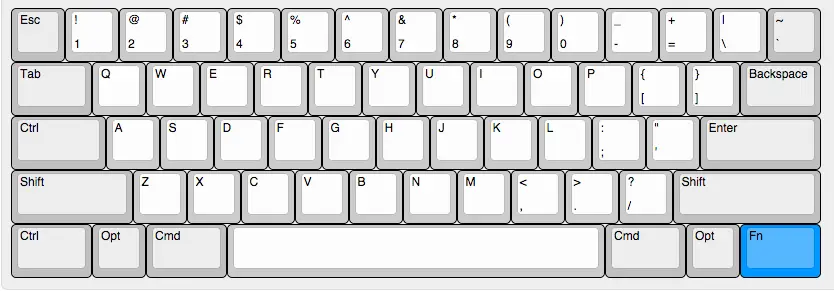

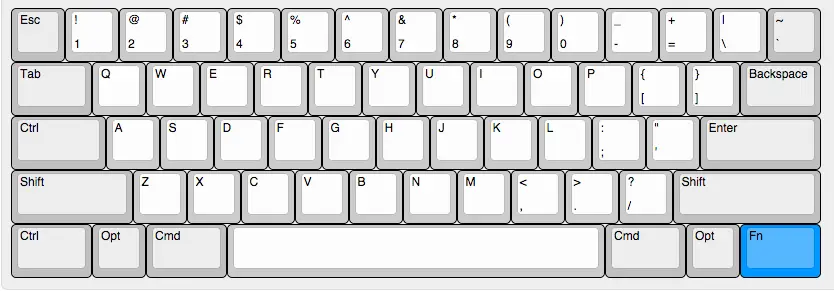

The key cap legends are just there for visualization - all of these designs would be fully programmable. Some folks like the middle left key as a Caps Lock, other like it as a Ctrl, but I like that spot for Fn. All of my Fn chords seem to be on the right side of the board; I use Fn+RShift for caps lock, Fn+Delete for Insert, Fn+P for Print Screen, Fn+arrows for media functions, Fn+N to toggle the embedded number pad layer. I use 1.75 unit stepped caps to make it easy to find the arrow cluster by feel. The bottom row is 1.5, 1.25, 1.25, 2, 2.75, 1.25, 1.25, 1.75(stepped), 1, 1, 1. You could use a blank or standard printed backspace for the erase-eaze and a blank right shift for the space. And because of IBM's great switch this is easy to convert between ISO and ANSI. We could build a prototype without the curve using sandwich layered case design for simplicity.

- skrsh3r

- Location: Serbia

- Main keyboard: Model M

- Main mouse: imo 1.1

- Favorite switch: buckling spring

- DT Pro Member: -

Code should be 2.75, i also looked up those membranes wcass and it should be fairly easy to make nkro membranes with pyralux but ill leave that in case we cant get capacitive pcbs to work with custom layouts, i wanted to know does trace thickness or how you rout them mater on capacitive pcbs if we can rout however we want i could draw pcbs fairly fast i just need kickad footprints.

- 0100010

- Location: DFW TX, US

- Main keyboard: IBM 4704 107

- Main mouse: Trackman FX

- Favorite switch: Buckling Spring

- DT Pro Member: -

The PCB wcass used for his XTant is here in PDF form : https://geekhack.org/index.php?topic=51767.0

- Hypersphere

- Location: USA

- Main keyboard: Silenced & Lubed HHKB (Black)

- Main mouse: Logitech G403

- Favorite switch: Topre 45/55g Silenced; Various Alps; IBM Model F

- DT Pro Member: 0038

My choice would be the HHKB Pro 2 layout. I've adjusted the bottom row for a 7.00x spacebar and mods at 1.50x and 1.00x.

If necessary, the short Right Shift with 1.00x Fn key could be replaced by a standard Right Shift, and the bottom row adjusted to place a Fn key to the far right.

Possible alternatives for me would be a couple of different versions of a modified TKL layout -- to be posted later.

If necessary, the short Right Shift with 1.00x Fn key could be replaced by a standard Right Shift, and the bottom row adjusted to place a Fn key to the far right.

Possible alternatives for me would be a couple of different versions of a modified TKL layout -- to be posted later.

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

There are not a lot of Code key caps out there and Unicomp is not making more of them. You would need two per keyboard. The profile of the Space and Code keys is nice, but I don't think that I would have a problem using the standard key profile; I've always used my thumb on the Alt key anyway.

After playing with the flat mock-up, I swapped the 2x and 2.75x keys on the bottom row. This puts the split down the middle of the B key - where it feels right to my hands.

After playing with the flat mock-up, I swapped the 2x and 2.75x keys on the bottom row. This puts the split down the middle of the B key - where it feels right to my hands.

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

I do most of my PCB design work in DeltaCAD then import that into DipTrace. KiCAD doesn't import complex DXF files very well.

Design rules:

Design rules:

- all rows must cross all columns exactly one time. This can lead to some curious traces

all column and row traces are 0.020" thick

all column pads and traces have a parallel ground trace - 0.050" thick, 0.025" gap

- 0100010

- Location: DFW TX, US

- Main keyboard: IBM 4704 107

- Main mouse: Trackman FX

- Favorite switch: Buckling Spring

- DT Pro Member: -

If you can deal with swapping the short right shift and the 1x function keys, that layout would work on the Kishsaver (if you add in bottom outside corner 1.5x mods).Hypersphere wrote: ↑My choice would be the HHKB Pro 2 layout. I've adjusted the bottom row for a 7.00x spacebar and mods at 1.50x and 1.00x.

If necessary, the short Right Shift with 1.00x Fn key could be replaced by a standard Right Shift, and the bottom row adjusted to place a Fn key to the far right.

Possible alternatives for me would be a couple of different versions of a modified TKL layout -- to be posted later.

- 0100010

- Location: DFW TX, US

- Main keyboard: IBM 4704 107

- Main mouse: Trackman FX

- Favorite switch: Buckling Spring

- DT Pro Member: -

I think the real question is how many layouts would people truly want, and how many of each layout could be ordered to make it economical. Like the normal Kishaver barrel positions support HHKB layout as is, provided when the right shift is split the shift is on the outside and the function key on the inside. Could probably add a couple barrels on the bottom row to support Code keys, or some other mods.wcass wrote: ↑There are not a lot of Code key caps out there and Unicomp is not making more of them. You would need two per keyboard. The profile of the Space and Code keys is nice, but I don't think that I would have a problem using the standard key profile; I've always used my thumb on the Alt key anyway.

After playing with the flat mock-up, I swapped the 2x and 2.75x keys on the bottom row. This puts the split down the middle of the B key - where it feels right to my hands.

I think that having one layout that everyone can agree on, that is 'modifiable' enough based on keys used - would be best; only from a position of getting the order quantity up to lower the cost per unit.

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

Below is what i have so far for a 60% (64 actual capacitive pads set up in an 8x8 array). There should be room to put xwhatsit's controller on the matrix PCB. It would support Hypersphere's and 0100010's preferred key layouts - the only difference being the top layer of the sandwich on Hypershere's would not have holes for the bottom corner keys.

-

jacobolus

- Location: geekhack ergonomics subforum

- Favorite switch: Alps plate spring; clicky SMK

- DT Pro Member: -

I have 16 code keys to use for this (and also access to a waterjet (at $3/minute + my own labor) and a slip roll). So I can make 8 keyboards. Not as many as I’d like perhaps, but still enough to cut costs a bit by going in together with some other people. Still takes designing and ordering PCBs and figuring out a case. Anyway, not my most immediate project, but I’ll definitely get to it eventually.wcass wrote: ↑There are not a lot of Code key caps out there and Unicomp is not making more of them. You would need two per keyboard.

- 0100010

- Location: DFW TX, US

- Main keyboard: IBM 4704 107

- Main mouse: Trackman FX

- Favorite switch: Buckling Spring

- DT Pro Member: -

16 code keys?!? (I only have one - need more.)jacobolus wrote: ↑I have 16 code keys to use for this (and also access to a waterjet (at $3/minute + my own labor) and a slip roll). So I can make 8 keyboards. Not as many as I’d like perhaps, but still enough to cut costs a bit by going in together with some other people. Still takes designing and ordering PCBs and figuring out a case. Anyway, not my most immediate project, but I’ll definitely get to it eventually.wcass wrote: ↑There are not a lot of Code key caps out there and Unicomp is not making more of them. You would need two per keyboard.

Slip Roll?!? (IMO it's not really a BS board unless the plates are curved.)

Waterjet access?!? (drool)

Sounds like Christmas. Sadly, I think the only things I could contribute, is ideas and money. I'm with you though on the not immediate part - but without question eventually.

- Hypersphere

- Location: USA

- Main keyboard: Silenced & Lubed HHKB (Black)

- Main mouse: Logitech G403

- Favorite switch: Topre 45/55g Silenced; Various Alps; IBM Model F

- DT Pro Member: 0038

Looking good! Would it be possible to include additional optional pads on the HHKB layout in case I wanted to add barrels later on, or would I need to commit to a specific PCB? If you are able to make a new PCB with a standard HHKB layout, this would be great. The only reason I can think of deviating from this is if it is not possible for some reason to do the short Right Shift with a 1x Fn key on its right side. But if you are making the PCB from scratch, I suppose this would not be an issue.wcass wrote: ↑Below is what i have so far for a 60% (64 actual capacitive pads set up in an 8x8 array). There should be room to put xwhatsit's controller on the matrix PCB. It would support Hypersphere's and 0100010's preferred key layouts - the only difference being the top layer of the sandwich on Hypershere's would not have holes for the bottom corner keys.

<snip>

Looking ahead to physical production, how difficult would it be to make a curved barrel plate (along with the curved back plate)? Alternatively, how expensive would it be to have curved plates made?

- 0100010

- Location: DFW TX, US

- Main keyboard: IBM 4704 107

- Main mouse: Trackman FX

- Favorite switch: Buckling Spring

- DT Pro Member: -

Function key on the right side of a short right shift would be unique and would not support a standard normal size right shift - but it is doable.Hypersphere wrote: ↑Looking good! Would it be possible to include additional optional pads on the HHKB layout in case I wanted to add barrels later on, or would I need to commit to a specific PCB? If you are able to make a new PCB with a standard HHKB layout, this would be great. The only reason I can think of deviating from this is if it is not possible for some reason to do the short Right Shift with a 1x Fn key on its right side. But if you are making the PCB from scratch, I suppose this would not be an issue.wcass wrote: ↑Below is what i have so far for a 60% (64 actual capacitive pads set up in an 8x8 array). There should be room to put xwhatsit's controller on the matrix PCB. It would support Hypersphere's and 0100010's preferred key layouts - the only difference being the top layer of the sandwich on Hypershere's would not have holes for the bottom corner keys.

<snip>

Looking ahead to physical production, how difficult would it be to make a curved barrel plate (along with the curved back plate)? Alternatively, how expensive would it be to have curved plates made?

I'm with you on extra barrels - specifically for splitting the spacebar to fit two code keys in either side of a center key.

Only difference between a normal plate and a curved plate is putting it through a slip roll at the right offset to bend it to the correct radius, after it has been water or laser cut for screw and barrel holes. Cost of the plates I would expect to be not much more than other keyboard plates. Each assembly would need to be a bottom plate, some spacers for the perimeter, a top plate and potentially a face plate.

We may also want to make the barrel holes hybrid - so they can support both XT and AT type barrels.

- Hypersphere

- Location: USA

- Main keyboard: Silenced & Lubed HHKB (Black)

- Main mouse: Logitech G403

- Favorite switch: Topre 45/55g Silenced; Various Alps; IBM Model F

- DT Pro Member: 0038

Okay, if it would be problematic to have a short Right Shift with a 1x Fn key to its right, here is a revised layout that should enable standard-size IBM/Unicomp keys to be used:

- wcass

- Location: Columbus, OH, USA

- Main keyboard: ibm model m

- Main mouse: kensington expert mouse

- Favorite switch: buckeling spring

- DT Pro Member: 0185

A stepped right shift + 1x Fn key on the right would not be a problem, it just means that a "standard" right shift would not be an option. But I'm not hearing from anyone (here anyway) that wants a standard right shift. Also, extra pads are not a problem - ISO, ANSI, and 2x backspace all have two capacitive pad sets under them. But the holes in the top plate for the "optional" barrels might be an issue. Maybe have a layer on top of the barrel frame made from a material easier to work with - acrylic, wood, or even leather.

Jacobolus, i might ask you for one of those Code keys just to take some measurements.

Jacobolus, i might ask you for one of those Code keys just to take some measurements.

- 0100010

- Location: DFW TX, US

- Main keyboard: IBM 4704 107

- Main mouse: Trackman FX

- Favorite switch: Buckling Spring

- DT Pro Member: -

I could go either way myself with respect to right shift, much like Hypersphere (function there or function on the bottom row).

I can see some folks wanting to make a Kish clone (meaning standard right shift), and others wanting to make a HHKB clone (split right shift not compatible with standard), while others want something different (like some of the stuff you and I have been posting with split spacebars, extra mods).

Maybe there is enough interest to make all of them, but maybe there is only enough to make one. If there can only be one, makes sense to me to make a PCB that is most compatible with as many layouts as possible.

If we can do multiple PCBs, then kind of a moot point.

I can see some folks wanting to make a Kish clone (meaning standard right shift), and others wanting to make a HHKB clone (split right shift not compatible with standard), while others want something different (like some of the stuff you and I have been posting with split spacebars, extra mods).

Maybe there is enough interest to make all of them, but maybe there is only enough to make one. If there can only be one, makes sense to me to make a PCB that is most compatible with as many layouts as possible.

If we can do multiple PCBs, then kind of a moot point.

- Hypersphere

- Location: USA

- Main keyboard: Silenced & Lubed HHKB (Black)

- Main mouse: Logitech G403

- Favorite switch: Topre 45/55g Silenced; Various Alps; IBM Model F

- DT Pro Member: 0038

I am fine with either a Kishsaver clone (with a standard Enter/Return key and Fn on the bottom row) or a HHKB clone. The bottom row on the Kishsave clone could be as depicted in my layout above (1.25, 1.00, 1.25, 7,00, 1.25, 1.00, 1.00, 1.25) or as it is on the actual Kishsaver (1.50, 1.00, 1.50, 7.00, 1.50, 1.00, 1.50).

It would be nice, however, if we could avoid having to use stepped 1.75x keys, except perhaps for the customary CapsLock position. Although the traditional Right Shift seems like a waste of space with its ridiculous 2.75x units, I would prefer having a normal key there rather than a stepped key.

It would be nice, however, if we could avoid having to use stepped 1.75x keys, except perhaps for the customary CapsLock position. Although the traditional Right Shift seems like a waste of space with its ridiculous 2.75x units, I would prefer having a normal key there rather than a stepped key.

- 0100010

- Location: DFW TX, US

- Main keyboard: IBM 4704 107

- Main mouse: Trackman FX

- Favorite switch: Buckling Spring

- DT Pro Member: -

Unfortunately, non stepped 1.75x BS keys are a rare thing. I do recall some discussion of cutting down a 2.75x right shift, using some kind of resin or epoxy to fill in the step, or one could purchase a Japanese key set from Unicomp to get its short non stepped right shift (but last I checked they didn't have many left - and I am not willing to A, spend that much to get one key and B, deplete their stocks of that key just for this).

- scottc

- ☃

- Location: Remote locations in Europe

- Main keyboard: GH60-HASRO 62g Nixies, HHKB Pro1 HS, Novatouch

- Main mouse: Steelseries Rival 300

- Favorite switch: Nixdorf 'Soft Touch' MX Black

- DT Pro Member: -

It might make more sense to have 1.5 + 1.25 instead of 1.75 + 1.0. It's not a perfect HHKB, but it works.

- Hypersphere

- Location: USA

- Main keyboard: Silenced & Lubed HHKB (Black)

- Main mouse: Logitech G403

- Favorite switch: Topre 45/55g Silenced; Various Alps; IBM Model F

- DT Pro Member: 0038

To minimize the need for 1.75x keys, I would be happy with Revision 1 of the HHKB layout above, or with Revision 2, shown below:

- Hypersphere

- Location: USA

- Main keyboard: Silenced & Lubed HHKB (Black)

- Main mouse: Logitech G403

- Favorite switch: Topre 45/55g Silenced; Various Alps; IBM Model F

- DT Pro Member: 0038

Yes, I know that Fn is ideally placed to the right of a 1.75x Right Shift, but because of the system constraints, I am willing to compromise (a word that always sticks in my throat!) and move Fn to the lower right-hand corner of the keyboard. This is the placement I use on all my "standard" keyboards, such as my RF 87ub 55g. And I still use my pinky. This arrangement is actually slightly more comfortable for me than the Fn placement on the true HHKB because it is slightly less cramped. I've tried putting Fn a bit more to the left in the bottom row and this doesn't work for me at all -- far too cramped.Muirium wrote: ↑No HHKB pinkie Fn = no HHKB.

-

andrewjoy

- Location: UK

- Main keyboard: Filco ZERO green alps, Model F 122 Terminal

- Main mouse: Ducky Secret / Roller Mouse Pro 1

- Favorite switch: MX Mount Topre / Model F Buckling

- DT Pro Member: 0167

Unicomp need to make the caps lock sized cap without the step in it. Don't they know all the problems they are causing ? We know the mould exists somewhere as we have seen a key that size.

- Hypersphere

- Location: USA

- Main keyboard: Silenced & Lubed HHKB (Black)

- Main mouse: Logitech G403

- Favorite switch: Topre 45/55g Silenced; Various Alps; IBM Model F

- DT Pro Member: 0038

@andrewjoy: Regarding 1.75x keys, is the only limitation getting 1.75x keycaps?

@wcass: I am not certain about what you said about your PCB designs. Are you saying that it IS possible to have a 1.75x Right Shift with a 1.00x Fn key to the right of the Right Shift?

I know that the standard IBM layouts currently available have these keys reversed. You either need to use a 2.75x Right Shift or you can have 1.00x to the left of a 1.75x Right Shift (actually a Caps Lock key).

If wcass can make a PCB with a 1.75x Right Shift and 1.00x Fn key to the right of Right Shift, then it is just down to finding or making a non-stepped 1.75x keycap.

@wcass: I am not certain about what you said about your PCB designs. Are you saying that it IS possible to have a 1.75x Right Shift with a 1.00x Fn key to the right of the Right Shift?

I know that the standard IBM layouts currently available have these keys reversed. You either need to use a 2.75x Right Shift or you can have 1.00x to the left of a 1.75x Right Shift (actually a Caps Lock key).

If wcass can make a PCB with a 1.75x Right Shift and 1.00x Fn key to the right of Right Shift, then it is just down to finding or making a non-stepped 1.75x keycap.

-

andrewjoy

- Location: UK

- Main keyboard: Filco ZERO green alps, Model F 122 Terminal

- Main mouse: Ducky Secret / Roller Mouse Pro 1

- Favorite switch: MX Mount Topre / Model F Buckling

- DT Pro Member: 0167

i think so yes you could just have it fit over a cap like control or alt do on a model m

it may be worth asking unicomp what it would cost for them to tool up for them i know many people would want them jsut for standard boards as well, i would like one with control on it for my 122 for example.

is the best layout with standard caps imo

is the best layout with standard caps imo

it may be worth asking unicomp what it would cost for them to tool up for them i know many people would want them jsut for standard boards as well, i would like one with control on it for my 122 for example.

is the best layout with standard caps imo

is the best layout with standard caps imo

Last edited by andrewjoy on 08 Dec 2014, 00:03, edited 1 time in total.