Sorry for the length. This is just a complex topic, and it is difficult to do without girth. Also... just for clarity to everyone because I am not calling this out the best on these posts. Everything being discussed here is for PHASE 2 (new board), with a current desired to test a flat approach to the plates with Cherry adapters in a brand new case. This might all fall flat on its face, but I am going to try because all of my testing is showing that this would work. PHASE 1 is still the drop-in replacement as true to factory as possible.

I realize you were both aware of that, but wanted to call out for others.

chzel wrote: DMA, the barrel distance is not 19mm on the M, they are further apart because of the curved plate. As the barrels extend "upward" the get closer together and end up ~19mm apart. So going to a flat plate you need to close that extra gap.

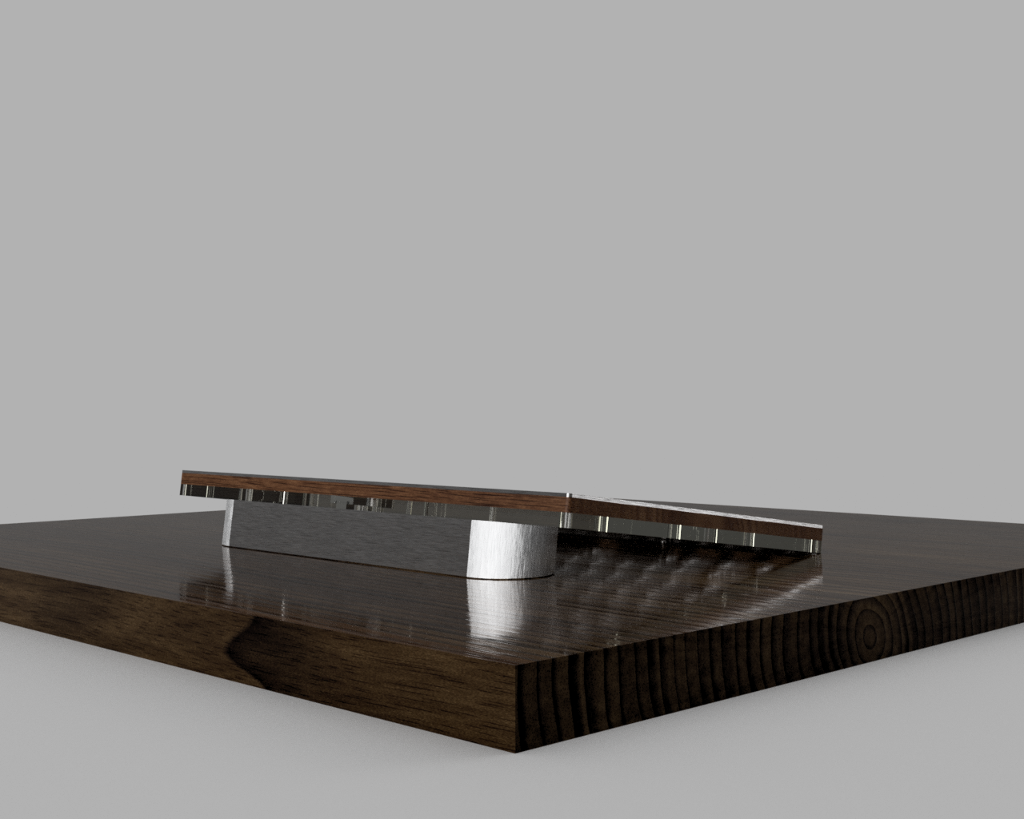

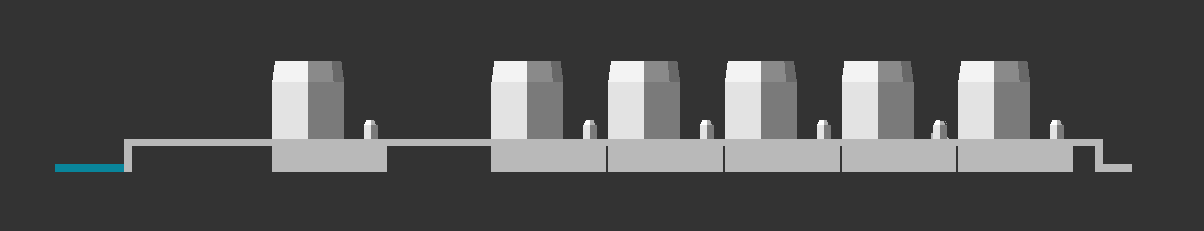

Exactly... The compression was in regards to the spacing between the key ROWS (should have called out better previously). When we flatten the board, the spacing between the rows t the point of key cap surface is widened because we are no longer sitting inside an arced plane. So to return back to the original key spacing, the barrels have to be tightened vertically by 1.45mm (EDIT: originally stated .45mm). I thought we might have to alter the barrel designs from original to allow for the tighter spacing, but this turned out not to be the case (which is good)

- Flat top plate after 1.45mm (EDIT: originally stated .45mm) row compression. It's tight, but very manageable for barrel installation. Also, you see how much the F-row could be brought down if we had the desire

- topPlateRowSpacing.png (1.73 KiB) Viewed 5380 times

DMA wrote: lot_lizard wrote: we would likely only offer one version of the board for phase 2 given mold pricing.

So the additional cost of a quieter version would be approx. $10 USD for the SSK, and $12 USD for the 101-key.

$12 over $200 is one thing, $12 over $100 is a completely different one. Another question is "will there be different keystems for the different rows?" Because if stems are different - wouldn't it mean 5 different molds hence 5x tooling costs?

Another possibility is to just publish the models and let people who want silenced versions print them. Doable unless you want custom O-rings, IMO. Don't know how much it will cost though. $50? $100?

Yet another possibility is separate group buy if enough takers. If the new keystems are compatible with

model M - that will definitely expand the audience.

I want to reiterate that "without altering the feel" is the key (pardon the pun). Can't improve on that - in no small part because there will be fight to the death about the definition of "improve"

Completely agree with all of that... And this is probably a little early yet for me to have even asked this until we see (including me) a working

model. I do think we will have noticeable audible improvement, and am expecting close to zero difference in actual feel. For the number of molds (think parts, not physical molds), we would need the following for both a standard and "silenced" version. Those with a preceding asterisk would be candidates for printing because of lower volumes

- Standard F barrel (currently slated to be a peg lock)

- Type-S standard barrel

- * Spacebar stabilizer barrel

- * Type-S spacebar stabilizer barrel

- * Vertical stabilizer barrel (Enter and + for the 10-key)

- * Type-S vertical stabilizer barrel

- Flipper

- * Phase 1 Plate spacer (I will test with and without to see if there is even any improvement). Phase 2 would be a completely different design

- Standard Cherry keystem (likey Type-S only)

- * Spacebar Cherry keystem (again Type-S)

If we can refactor the barrel placement slightly for the special keys, they would be able to use the universal Cherry stem as well (which has huge cost impact). So from the above, we would have 4 parts that HAVE to be injection molded to keep costs down (ideally more). The way molds work, you can have multiple parts in a single mold. These could be either redundant parts, or unique parts. There is a balance that will be performed to get those ratios just right, and is directly tied to the size of the press, material used, and the volume of parts in the run. Each additional part adds cost to tooling, but it really isn't horrid. Example, if you are producing two similar but unique parts, the cost of the tooling is much less than double the cost (think only 10-20% increase per part) if you are able keep the some number of physical molds.

Again... it was probably premature to ask about the cost increase earlier until we know more. Still a good deal of research ahead (both of functionality and actual cost). But I would assume it is in the neighborhood of 11-13 cents a key over the cost of a standard key if only producing a Type-S version, and closer to double that increase if we are offering both. Just wanted to make sure there was actual interest in the Type-S concept, because I will have time in it that could be avoided if undesirable. It is a fun academic practice, but would anyone actually want it? I will ask again once I have the working models tested (more clarity then), but chew on it