Page 43 of 73

Posted: 04 Oct 2016, 21:37

by E TwentyNine

lot_lizard wrote: E TwentyNine wrote: Regarding combining keys, it would seem the smaller of the two keys wouldn't sit proper in the template, as well as the gap between the keys entering into the width equation.

They would be dedicated spaces. I will have the current layout "as-is", and then add extra keys 'round the outside (Eminem reference... at least I think. It's been a while)

OK. wcass's suggestion seemed to imply a two-for-one setup which would add the need for an spacer of some sort when using the smaller key (or two keys) in that position.

Posted: 05 Oct 2016, 03:34

by wcass

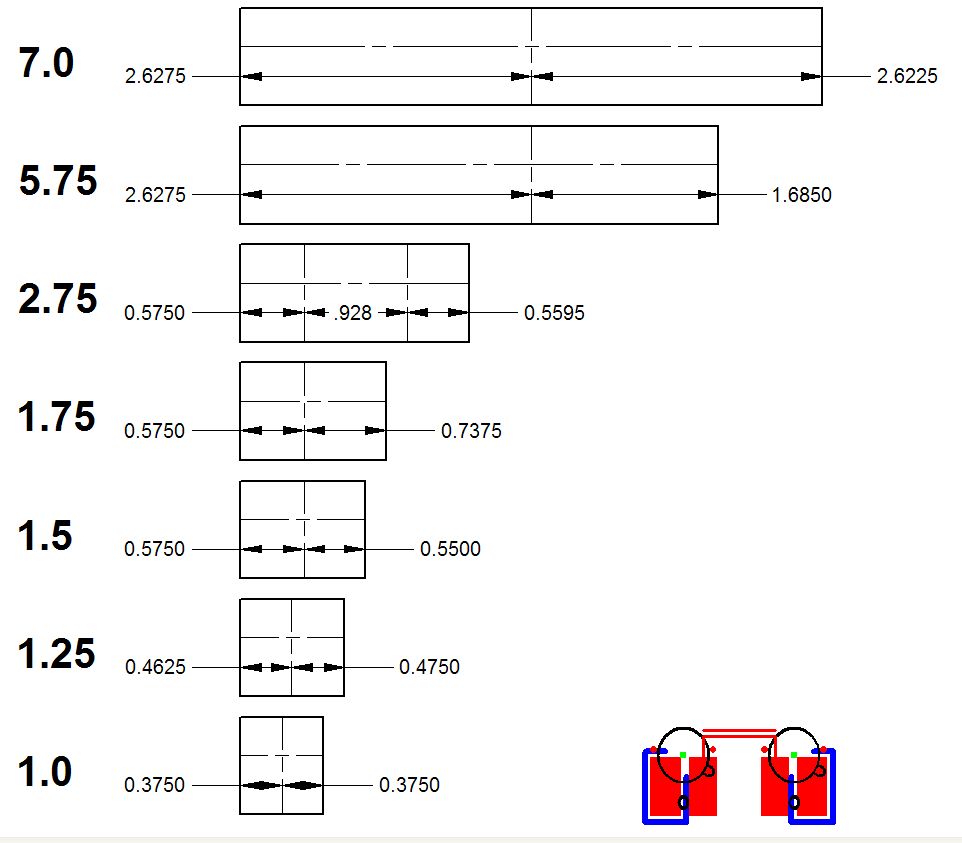

This is the spacing i use.

- Model F key spacing.jpg (70.1 KiB) Viewed 6083 times

If you prefer metric ...

1u = 19 = 9.5 + 9.5

1.25u = 23.75 = 11.75 + 12

1.5u = 28.5 = 14.5 + 14

1.75u = 33.25 = 14.5 + 18.75

Code = 52.25 = 14.5 + 23.5 + 14.25

5.75u space = 109.25 = 66.75 + 42.5

7u space = 133 = 66.75 + 66.25

20.5mm row height

I place these boxes corner to corner to build key clusters (space between keys is built-in).

Posted: 05 Oct 2016, 19:39

by lot_lizard

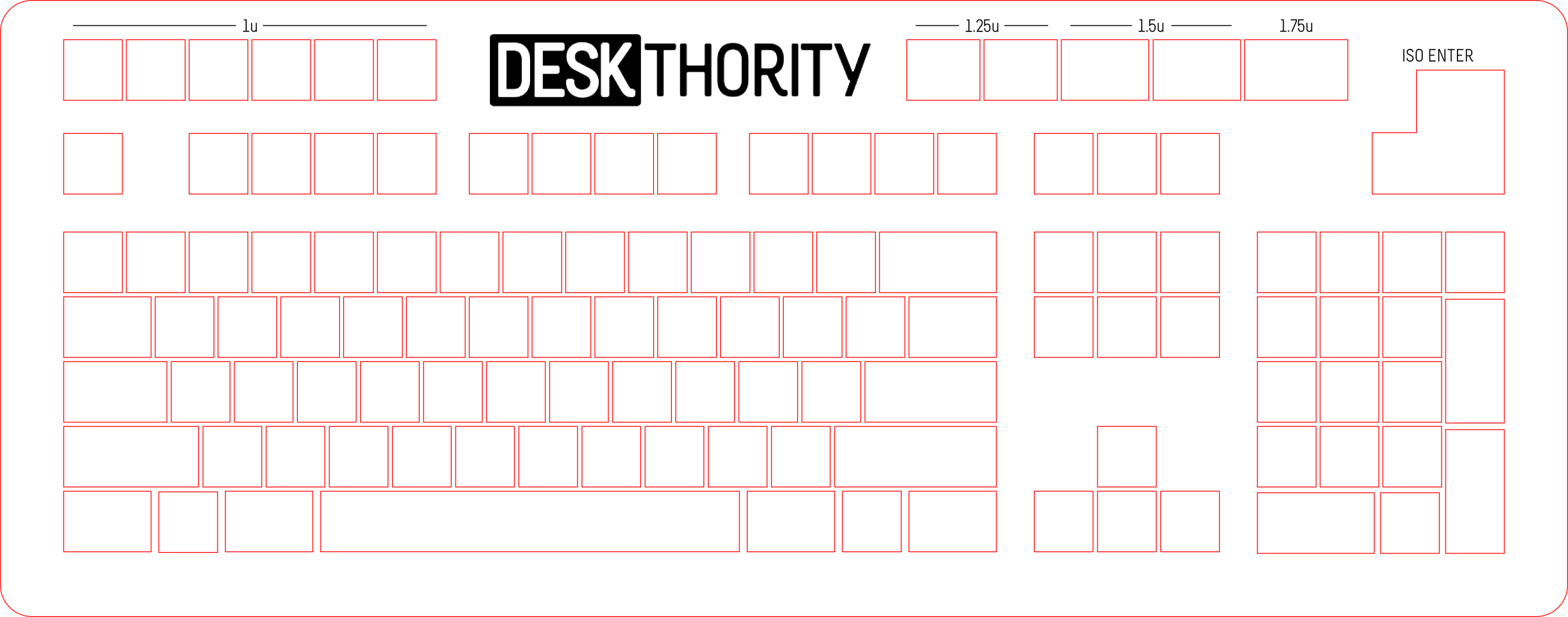

With updates... I believe this accounts for variations we mentioned, but a double checks are appreciated.

- laserCutLayout.png (35.12 KiB) Viewed 6020 times

Posted: 05 Oct 2016, 19:49

by E TwentyNine

That's the BAE. ISO enter is vertical.

Posted: 05 Oct 2016, 19:59

by lot_lizard

Sounds good... does anyone know if that is identical to the XT enter? Otherwise I need measurements.

EDIT: just looked. It's not. Need some help there with measurements

Posted: 05 Oct 2016, 20:09

by Ratfink

XT enter is 1u wide; ISO enter is 1.25u wide for the bottom half, 1.5u wide for the top half.

Posted: 05 Oct 2016, 21:34

by lot_lizard

Ratfink wrote: XT enter is 1u wide; ISO enter is 1.25u wide for the bottom half, 1.5u wide for the top half.

Thanks... With updates below.

This is a bit trickier than typical key spacing, because I am wanting .1mm tolerance (all sides) in the jig around the cap itself. I am wanting to turn on air-assist with this engraving process since we will be burning off 100+ caps at a time, and there will potentially be some smoke as the ink/plastic vaporizes. My compressor only goes down to 10psi (2/3 bar) reliably, and it will blow these light little caps around if they aren't secured properly in the jig. It's the real reason for wanting dedicated cap size spaces versus overloading. Smoke isn't a huge deal, but if there is enough of it... the laser looses focus. Might be overkill... but doesn't hurt.

- laserCutLayout.png (36.83 KiB) Viewed 5993 times

Posted: 06 Oct 2016, 10:30

by andrewjoy

so is split backspace and split numb pad + still an option ?

Posted: 06 Oct 2016, 10:52

by lot_lizard

andrewjoy wrote: so is split backspace and split numb pad + still an option ?

In that example, you would just use the spare 1u's at the top, and leave out the standard locations when filling out the pattern. But I believe the combinations we mentioned before can be accounted for with these extras. I might shrink down or 86 the logo to make more room for 1u's in the end, or as WCass mentioned... fill in the cursor key gaps. I can certainly make multiple runs as well if everything you needed didn't fit in one file. You can fill out as much of a template as you desired, even a single key is fine. I just have some spare acrylic sitting around, and this is about the limit of its size before it would force me to buy more

Also... the image you are seeing is for cutting the jig with the laser cutter. The template everyone will fill out in the end will look different. The caps will be smaller, only showing the engravable face of the cap, and there will be some sort of center cross-hair to you line everything up. You would take the SVG file template, add a new layer (so I can delete the template layer later when hitting "run"), and add anything you like over the top of any location. I just made it look like an actual keyboard to help you keep track of everything when filling it out.

Posted: 06 Oct 2016, 12:49

by lot_lizard

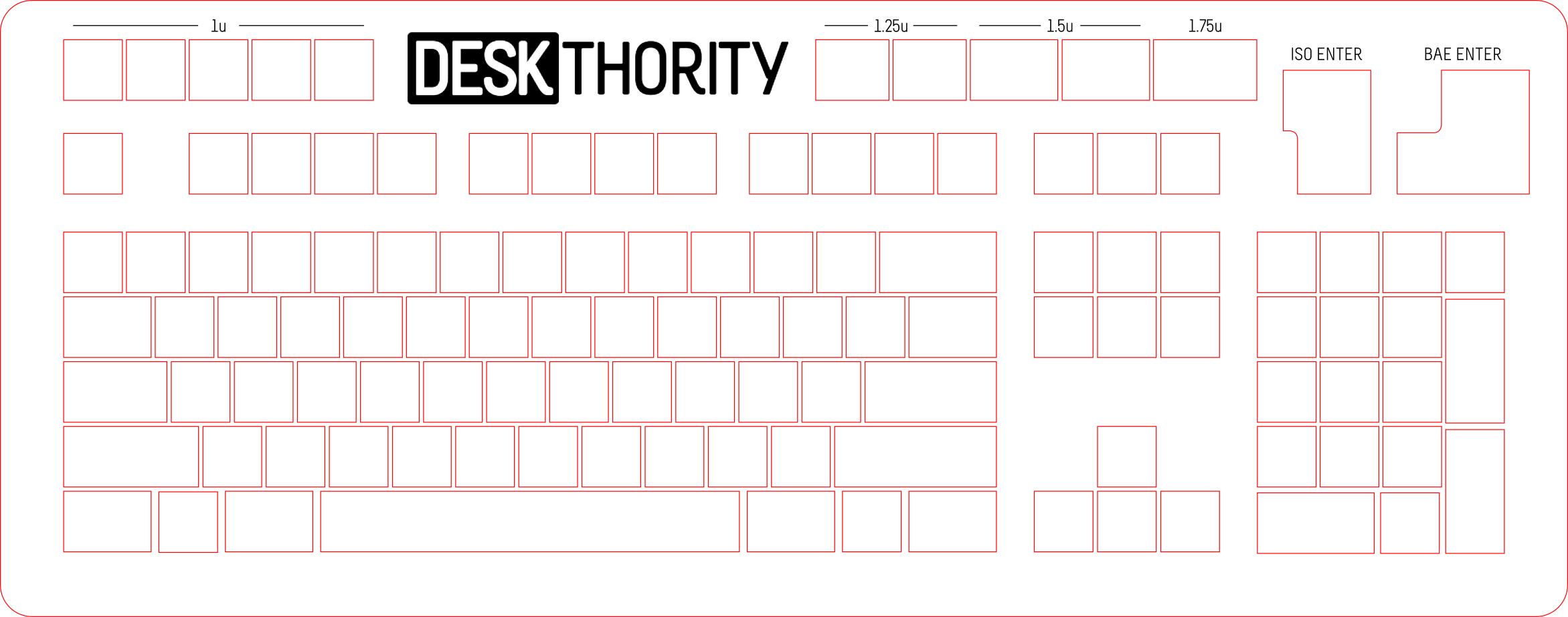

Since I know this isn't always the easiest to follow... I threw this together to better visualize what this jig is about, and to make sense why the template you will fill out later will be yet another SVG altogether.

The tool (jig) I am making is composed of multiple sheets of acrylic. Since we are allow for not only 2-piece cap tops, but wider keys... we will need to account for the key stems when the tool sits on the engraver bed. The red and black are what we have been looking at (red is a cut, black is engrave). This is the top layer that surrounds the caps and holds them steady laterally. The blue is another thicker acrylic sheet that will set beneath, and act as the lip that raises the caps off the engraver bed at a consistent flat height. I'll then bond these two layers (possibly 3, with 2 being the bottom "layer" since the engraver might struggle to cut 1/2 inch) together with some screw fasteners. We don't want to use adhesive since we might alter individual layers later.

Hopefully this makes more sense. I return from a work trip today, and will give it a go.

- laserCutLayout3.png (46.33 KiB) Viewed 5945 times

Posted: 06 Oct 2016, 14:04

by fohat

lot_lizard wrote:

Since I know this isn't always the easiest to follow...

The tool (jig) I am making is composed of multiple sheets of acrylic.

I feel dense to be asking, but what is this?

I looked back through the thread and didn't really see what it is all about.

Posted: 06 Oct 2016, 14:27

by lot_lizard

Not at all... This is a side effort while we are waiting on a few loose ends for phase 1 to wrap up. It is for laser engraving our caps. We had some success with dyeing caps, and then engraving off the dye (dark keys with light font).

This little tool will let you put whatever fonts/images you want onto a template file that matches up to this little jig. I would then just drop the caps you send me into the slots where you had added something to the template file, and hit RUN. It puts all the work on you to enter the template file correctly, but reduces any real work by me (just offering the engraver as a service). Also, it assures accurate results (better alignment than dye-sub).

It will make more sense once the tool is assembled, and I put together the template file that you would fill in. All academic at this point

Re: (Model MF) Remodeling the Model M

Posted: 06 Oct 2016, 15:05

by Techno Trousers

What software does everyone recommend for SVG editing? I tried Inkscape a couple of years ago, and it was so cumbersome I never went back.

Ideally I'd like to find something that works more like a regular graphics program (e.g. Paint.Net or Gimp). Windows or cross platform preferred.

Posted: 06 Oct 2016, 15:21

by andrewjoy

IF you want a drawing program try libre office draw thats not bad , bit simple but does the job.

I do flow charts etc on draw.io as i am too lazy to bother with anything more complex

Or you could just set up a Adobe CC trail and use illustrator

Re: (Model MF) Remodeling the Model M

Posted: 06 Oct 2016, 16:44

by Techno Trousers

Thanks! I also found a pretty

comprehensive Wikipedia page about vector drawing programs. I'll give some of these a try too and report back.

Posted: 06 Oct 2016, 16:48

by Wilkie

For vector graphics, I highly recommend

Inkscape.

Posted: 06 Oct 2016, 17:43

by lot_lizard

Techno Trousers wrote: What software does everyone recommend for SVG editing? I tried Inkscape a couple of years ago, and it was so cumbersome I never went back. Ideally I'd like to find something that works more like a regular graphics program (e.g. Paint.Net or Gimp). Windows or cross platform preferred.

Everything here was created with Inkscape, but it really had to be (or equivalent) to get the path precision. The Epilog driver needs paths to be .001 inch (hairline) for the engraver to recognize as a cut... otherwise it engraves/rasterizes. To be honest (like andrewjoy mentioned), as long as what you pick supports layers since you/I need to be able to delete the template coordinate layer before processing, anything will work. You guys will be engraving here. Just keep in my that if what you use dithers/pixelates to compensate for paths, the engraver will not hit that spot as hard. You would have to get a microscope out to notice (engraver only has a resolution of 1200dpi), but I know some of you are that picky. As long as you didn't change the scale and picked the right font point size to start with, Gimp would work fine. The only REAL advantage SVG is going to have for you would be if you wanted to adjust something other than positioning of the font after the fact.

Having said that... if picking something new, anything that works in actual objects and paths is an ideal choice for this stuff (it's two tone after all). Should also mention... the font color should be black. You are welcome to use lighter colors mixed in for different effects though, but the machine will be calibrated so that black is ideal.

Posted: 06 Oct 2016, 19:20

by lot_lizard

Last post and I'll stop bombing. I was going to throw this template together on the plane and NEED SOME HELP from you cap savants.

Can you give me every variation of stepped and non-stepped keys I have to think about? I know the 1.5u is one, but I can't think of others. Capslock seems like a candidate, but I don't recall ever seeing one that isn't stepped. 1.25u, ISO, whatever... The more you can think of that actually have variations in IBM cap land the better. So far... 1.5u is all I am aware of (or can recall at least).

Posted: 06 Oct 2016, 19:59

by fohat

lot_lizard wrote:

Can you give me every variation of stepped and non-stepped keys I have to think about?

Snuci posted these cool things this morning:

Posted: 06 Oct 2016, 21:13

by lot_lizard

Good point... Thinking about the silly XT guys is making want to avoid it altogether. Let's start with this, and we can always come back to the template and modify as requested (not a physical thing).

http://www.pckeyboard.com/page/product/mwide

I'm assuming the Unicomp blanks (the target of this exercise) are stepped for ISO Left Shift, ISO Enter, and Capslock. I have only ever ordered an ANSI APL set from them once. This BAE Enter slot is probably worthless due to lack of blanks, but leaving for the time being.

Posted: 06 Oct 2016, 22:14

by fohat

If you are talking about buying blanks and dyeing them, then Unicomp stock is probably about it.

I personally love stepped keys but I know that most people don't.

It won't help in the larger scheme, but I think that I have 2 Big-Ass Enters I could sell to somebody who really wanted one.

Posted: 06 Oct 2016, 22:52

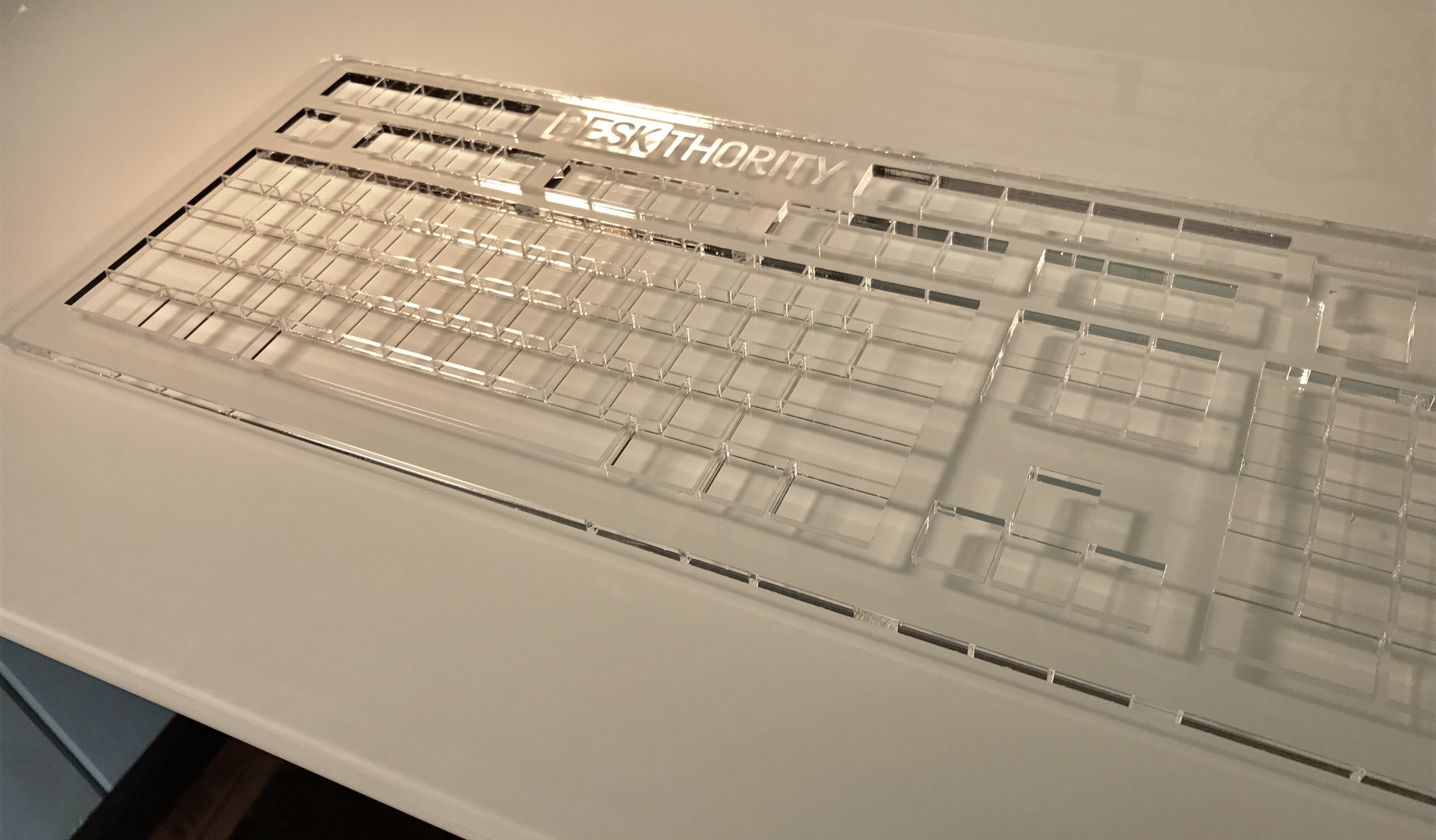

by lot_lizard

Short last connection, and plugged the plans in... Fits like a glove all the way around (surprised a bit actually

). This is the top plate of the jig. It would be the only, but we have some keys with stems, so we have to raise the deck for all

Hopefully this helps to visualize what's going on.

- Immediately after finishing in the cutter

- IMG_8976.JPG (2.57 MiB) Viewed 5835 times

- Resting on some glass

- IMG_8977.JPG (1.18 MiB) Viewed 5835 times

- With a 1u ready

- IMG_8978.JPG (1.15 MiB) Viewed 5835 times

Re: (Model MF) Remodeling the Model M

Posted: 06 Oct 2016, 23:18

by Techno Trousers

Wow, that's cool! Back to your question about stepped keys, I don't think the ISO left shift is stepped; at least not the F/M-122 and Unicomp versions of it.

Re: (Model MF) Remodeling the Model M

Posted: 06 Oct 2016, 23:20

by Techno Trousers

Ooh, semi-insane follow-up: Do you have any interest in lasering the *fronts* of keys? (Evil grin).

Posted: 07 Oct 2016, 00:20

by E TwentyNine

Techno Trousers wrote: Ooh, semi-insane follow-up: Do you have any interest in lasering the *fronts* of keys? (Evil grin).

I'm picturing Lizard at the premature end of all this in the nuthouse babbling - "the bastards wanted me to create etched tripleshots!"

Posted: 07 Oct 2016, 00:29

by fohat

E TwentyNine wrote:

etched tripleshot translucent PBT

Fixed that for you.

Posted: 07 Oct 2016, 01:15

by lot_lizard

Techno Trousers wrote: Ooh, semi-insane follow-up: Do you have any interest in lasering the *fronts* of keys? (Evil grin).

Not insane at all... I was going to kick the idea out too, but was afraid it was too soon to follow, and wanted this first pass to become viable. Front printing is actually a much more simplistic "tool"/template to produce.

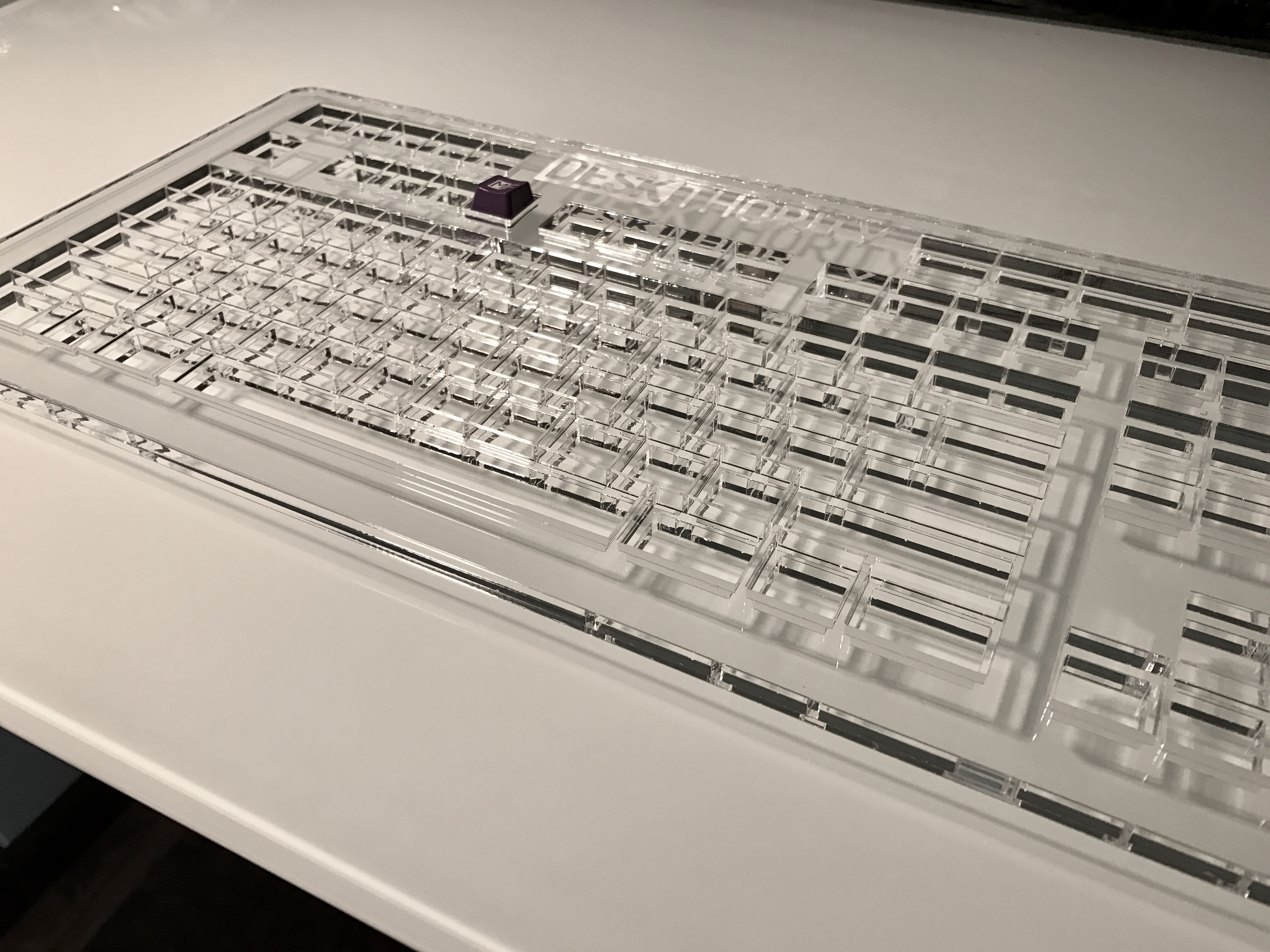

Finished cutting the second sheet of acrylic that will act as the key bed (not sure how easy it is to see in the pic given the clarity of everything). We will need to produce one more of this bed sheet to raise the stems the ~1/2 inch we need. Given how it is turning out, I do think I will go ahead and permanently bond the layers. Just more stable, and really don't envision this changing much (better then I had originally envisioned). If we need additional keys at some point, I'll just make a secondary layout altogether.

I am anxious to test it out. The template for you to fill out is close to complete (lacks 3/4 of the "weird" keys). I would start dyeing caps if I were you

- IMG_8984.JPG (1.9 MiB) Viewed 5754 times

Posted: 07 Oct 2016, 05:05

by wcass

FYI, on Unicomp web site, "old" set 104 has a bottom row that is [1.5 + 1.25 + 1.25] 5.25 spacebar not included [1.25 + 1.25 + 1.25 + 1.5] whereas the "new" set 104 has a bottom row that is [1.5 + 1 + 1.5] 5.25 spacebar not included [1.25 + 1.5 + 1 + 1.5].

Again, spacebars are NOT included in any of the sets and must be ordered separately.

Re: (Model MF) Remodeling the Model M

Posted: 07 Oct 2016, 05:32

by Techno Trousers

Anybody have a recommendation for a dye that would fairly closely match

Unicomp's blue legends, when dyed on brilliant white keys?

Posted: 07 Oct 2016, 17:52

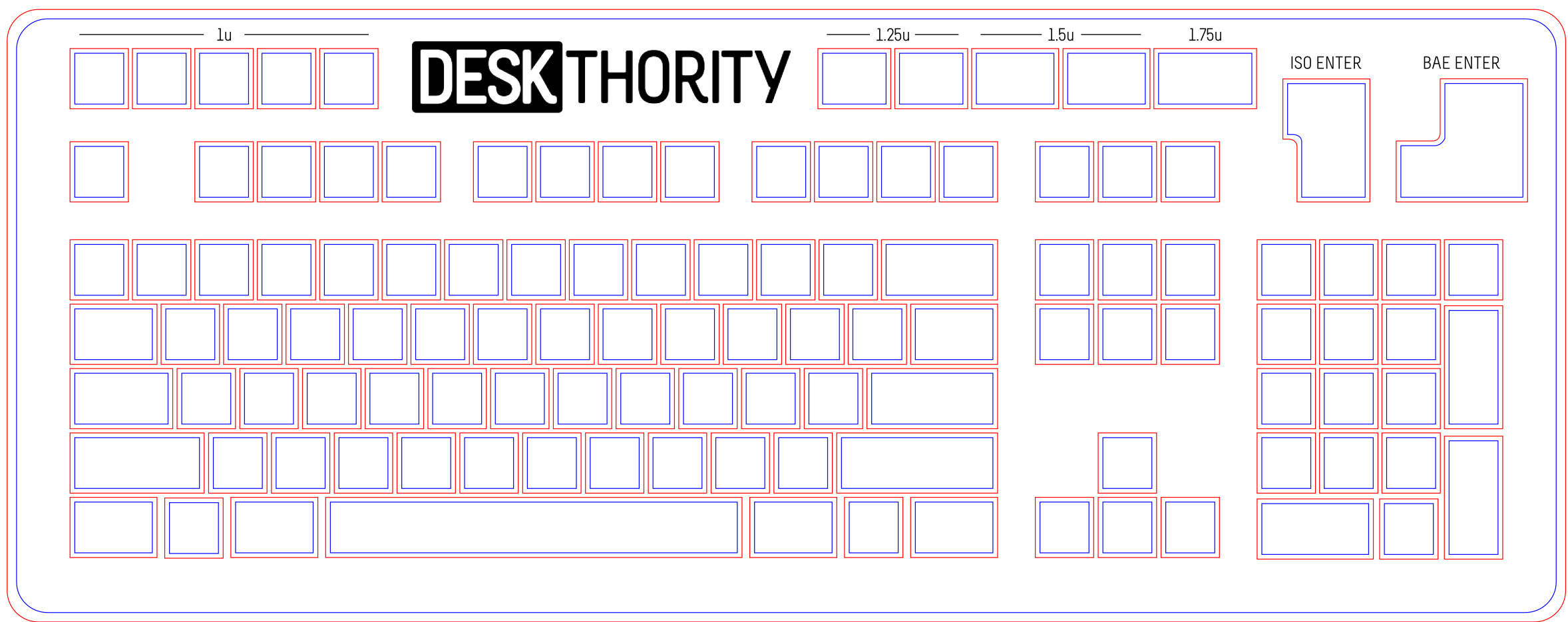

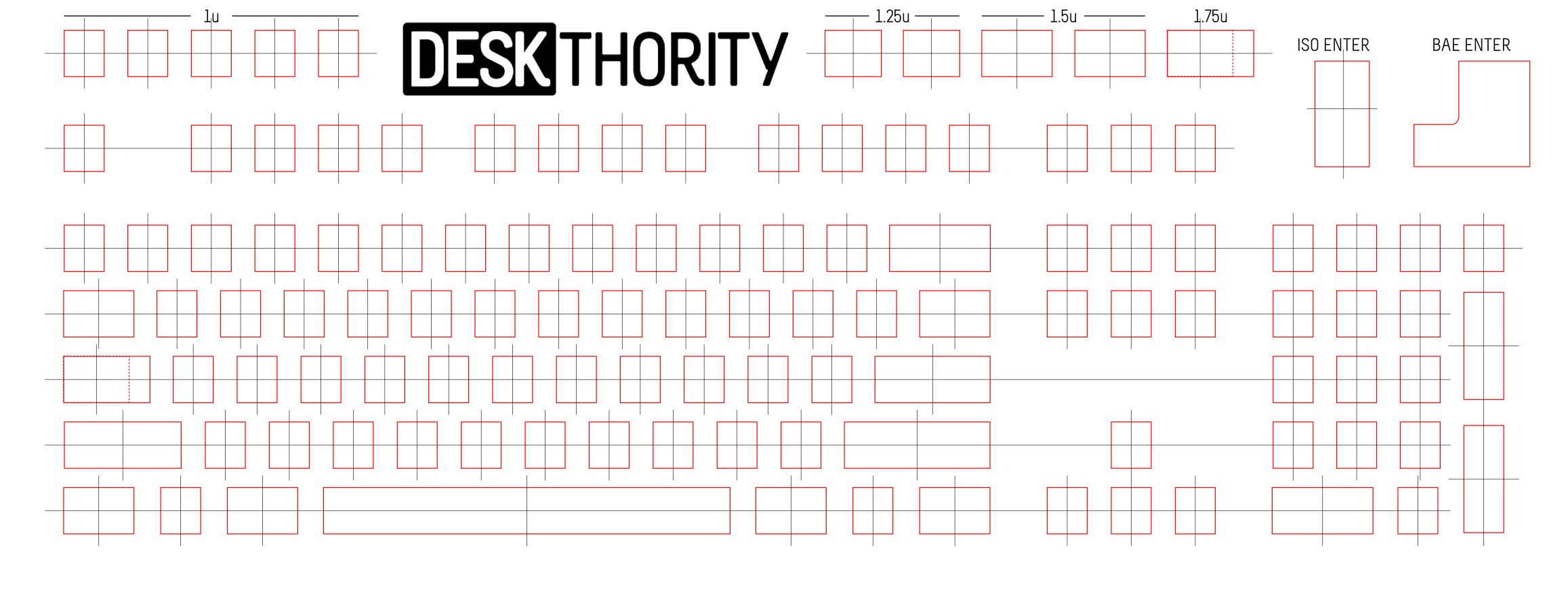

by lot_lizard

The template is ready to go (but extra reviews and thoughts are appreciated)... These are the key cap faces only, so line everything up like you would expect it to sit on the cap top. The red border is NOT part of the cap top, so make sure you sit everything inside. The cross hairs are a separate layer so you can get them out of the way if they are annoying you. Currently, Capslock is the only stepped key, and represented by a dashed line for the step. Remember...

YOU NEED TO CREATE A NEW LAYER FOR EVERYTHING YOU ADD. I will want to remove the template and cross hair layers so that the only thing that gets fed to the engraver is what you have added. If any of this is causing confusion or there are other inhibitors, please feel free to reach out. I would like to see this thing get utilized given the upfront work.

Attached is the zip file containing the SVG template, and an image representation of the template. Use the SVG in the zip file as the template, and not the image below as a starting point.

- dt_laser_engraving_template.png (51 KiB) Viewed 5640 times