Metal Case for 122 key model F?

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

All right, that is very comforting to hear. The use was probably it so I am relieved. I also like how mine does not have the dipswitches on the back as they serve no purpose(I think) and the back of the board looks better without it to me.

- joc

- Location: The Lone Star State

- Main keyboard: IBM F104 (Unsaver) || IBM SSK

- Main mouse: Logitech M570

- Favorite switch: IBM Beam Spring

- DT Pro Member: -

I've also noticed that my 122-key Model F's feel/sound different. I uploaded some sound samples here:

https://soundcloud.com/joc-23/sets/ibm- ... -keyboards

The keys on the '85 feel like they require a shorter travel distance to bottom out so I guess the plates on the '85 aren't sandwiched as tight together as the are on the '84.

https://soundcloud.com/joc-23/sets/ibm- ... -keyboards

The keys on the '85 feel like they require a shorter travel distance to bottom out so I guess the plates on the '85 aren't sandwiched as tight together as the are on the '84.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

After hearing those two samples, I think mine sounds a little more like the first one but not quite as much. Mine was made in September 85 so it was made later than your two were.joc wrote: I've also noticed that my 122-key Model F's feel/sound different. I uploaded some sound samples here:

https://soundcloud.com/joc-23/sets/ibm- ... -keyboards

The keys on the '85 feel like they require a shorter travel distance to bottom out so I guess the plates on the '85 aren't sandwiched as tight together as the are on the '84.

-

Ellipse

- Location: United States

- Main keyboard: Brand New Model F Keyboards

- DT Pro Member: -

- Contact:

joc - both those samples sound like you have some really nice F122s. I'd be fine with something sounding like either one of those. The first one is slightly more crisp.

Did you do any restoration to those F122s? What was the condition of the foam when you opened them up? Did you replace the foam or springs? Do the barrels of yours wobble a bit if you remove a key and try to move the barrel around?

Some Model F's have more of a quiet thudding - I prefer the sound like yours and mine.

I wonder what options there are for "tightening" the sandwich plates on Model F keyboards to help get a crisper sound.

Did you do any restoration to those F122s? What was the condition of the foam when you opened them up? Did you replace the foam or springs? Do the barrels of yours wobble a bit if you remove a key and try to move the barrel around?

Some Model F's have more of a quiet thudding - I prefer the sound like yours and mine.

I wonder what options there are for "tightening" the sandwich plates on Model F keyboards to help get a crisper sound.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

I'm sure you could do what Fohat did and do a bolt mod on the platesEllipse wrote: joc - both those samples sound like you have some really nice F122s. I'd be fine with something sounding like either one of those. The first one is slightly more crisp.

Did you do any restoration to those F122s? What was the condition of the foam when you opened them up? Did you replace the foam or springs? Do the barrels of yours wobble a bit if you remove a key and try to move the barrel around?

Some Model F's have more of a quiet thudding - I prefer the sound like yours and mine.

I wonder what options there are for "tightening" the sandwich plates on Model F keyboards to help get a crisper sound.

Looks a little scary in his guide but that might do the trick and also make the keyboard more solid in general. I can't make time to do my ANSI mod right now, but I am still pondering as to whether I should also bolt mod.

On another note, you think its the way that the keyboards are tightened and not the materials/hammers or springs that make the different sound? I love the sound of mine, but it would be good to know that we can all change the sound to something more appealing if we so choose.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Also, do you think that the tighter the plates are, the crispier the sound and feel?

Fohat, you could help here because you are the only one who has tightened their plates with a bolt mod that I know of.

Fohat, you could help here because you are the only one who has tightened their plates with a bolt mod that I know of.

- joc

- Location: The Lone Star State

- Main keyboard: IBM F104 (Unsaver) || IBM SSK

- Main mouse: Logitech M570

- Favorite switch: IBM Beam Spring

- DT Pro Member: -

Ellipse - Yeah, the first one is crisper/louder in person.

I haven't done any restorations to either keyboard and they've never been opened. Here are a couple pictures that will hopefully give you an sense of what condition the foams are in (the 6110344 is on the bottom):

The foam that's sticking out of the sides is nondense, dry, and brittle. I don't think it's necessarily the bad condition of the foam that's causing the sound because I have another Model F (early 1985) that is crisper/clackier/louder with foam that's in good condition.

On both keyboards, the barrels in the a-s-d-f row have some play but the barrels in the number row don't have any play.

Both assemblies look like they're sandwiched as tight as possible. Also, upon closer inspection, it looks like the keys on both keyboards have about the same amount of travel distance. Here are some pictures of the springs that show that they stick out about the same distance on both keyboards (the 6110344 is first):

At first I was leaning towards the tightness of the sandwich being the driving factor that affects the feel/sound but now I think it might be the springs.

I haven't done any restorations to either keyboard and they've never been opened. Here are a couple pictures that will hopefully give you an sense of what condition the foams are in (the 6110344 is on the bottom):

The foam that's sticking out of the sides is nondense, dry, and brittle. I don't think it's necessarily the bad condition of the foam that's causing the sound because I have another Model F (early 1985) that is crisper/clackier/louder with foam that's in good condition.

On both keyboards, the barrels in the a-s-d-f row have some play but the barrels in the number row don't have any play.

Both assemblies look like they're sandwiched as tight as possible. Also, upon closer inspection, it looks like the keys on both keyboards have about the same amount of travel distance. Here are some pictures of the springs that show that they stick out about the same distance on both keyboards (the 6110344 is first):

At first I was leaning towards the tightness of the sandwich being the driving factor that affects the feel/sound but now I think it might be the springs.

- fohat

- Elder Messenger

- Location: Knoxville, Tennessee, USA

- Main keyboard: Model F 122-key terminal

- Main mouse: Microsoft Optical Mouse

- Favorite switch: Model F Buckling Spring

- DT Pro Member: 0158

First, let me say that my obsolete original guide "Harry's Bolt-mod" (wherein I cut off alignment tabs) was a mistake and that I have deprecated it and attempted to remove it in favor of my revised "Harry's ANSI Mod" so that now I DO NOT RECOMMEND cutting off alignment tabs!

That said, it has been a year or 2 since I have opened an F-122 with re-useable foam, and I continue to use my "art foam" (a moderately dense foam approximately 1/16" or 1.5mm thick) because I like the firmness of it. I also think that it makes the keyboard feel much more solid, but whether or not it is more "crisp" - that is hard to define.

Adjectives describing sound and feel are hard for me to address, so let me say that to me, feel is paramount and sound is secondary. I floss-mod every F that I own, and pad the cases. Even if I did not live in a house with a wife and 2 kids, the "raw" sound of an F is annoying to me.

Having bolt-modded several Model Ms and understanding how they can be "tuned" by adjusting the tightness of the bolts, I always kept that in the back of my mind. My original "full" bolt mod and tab cutting came about out of frustration with the difficulty of re-assembling the "sliding force fit" of the plates, particularly after the addition of a thicker and denser pad.

More practice and $25 worth of clamps from the hardware store made the re-assembly process workable, although it still usually takes the better part of a half-hour and multiple attempts.

I believe that the incredible "liveliness" of the Model F is the result of the multiple steel plates in an assemblage of unresolved stresses of both tension and compression. Where deteriorating foam might make the assembly less tight and more prone to "rattle" I think that the thicker, stiffer foam adds to the internal stress and makes it both more solid and more alive.

The downside (after the difficulty of re-assembly has been overcome) is that the foam is forcing the plates apart at the center axis of their curvature. Unlike the smaller Fs, which only have tabs around the perimeter, the taller 122-key model has tabs down the center spine as well. While these should theoretically keep the plates tight, I don't think that they are always adequate, especially with firmer foam.

For that reason, I have settled on adding 3 screws down the center. I put them approximately between "5" and "F5", between "0" and "F10" and between "Enter" and "up arrow". It is easy to see where the traces run on the PCB, so make sure that you are drilling a blank field area. I drill in 2 operations such that the PCB is visible along with 1 plate the first time, to ensure that I am drilling a clear area, then I put the 3rd piece on and use the existing hole as an index. Make sure that the tabs are pushed to the fully closed position and do not allow the plates to slide while drilling.

These screws allow the plates to be pulled together tight along the innermost tangent of the axis of curvature and I crank them down fairly tight.

You can over-do it but you also get the opportunity to adjust it to your liking.

Size 4-40x1/2" (Imperial) or M3x8mm (metric) seems about right, and I use both steel and rubber washers if I can fit them in.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

fohat wrote:First, let me say that my obsolete original guide "Harry's Bolt-mod" (wherein I cut off alignment tabs) was a mistake and that I have deprecated it and attempted to remove it in favor of my revised "Harry's ANSI Mod" so that now I DO NOT RECOMMEND cutting off alignment tabs!

That said, it has been a year or 2 since I have opened an F-122 with re-useable foam, and I continue to use my "art foam" (a moderately dense foam approximately 1/16" or 1.5mm thick) because I like the firmness of it. I also think that it makes the keyboard feel much more solid, but whether or not it is more "crisp" - that is hard to define.

Adjectives describing sound and feel are hard for me to address, so let me say that to me, feel is paramount and sound is secondary. I floss-mod every F that I own, and pad the cases. Even if I did not live in a house with a wife and 2 kids, the "raw" sound of an F is annoying to me.

Having bolt-modded several Model Ms and understanding how they can be "tuned" by adjusting the tightness of the bolts, I always kept that in the back of my mind. My original "full" bolt mod and tab cutting came about out of frustration with the difficulty of re-assembling the "sliding force fit" of the plates, particularly after the addition of a thicker and denser pad.

More practice and $25 worth of clamps from the hardware store made the re-assembly process workable, although it still usually takes the better part of a half-hour and multiple attempts.

I believe that the incredible "liveliness" of the Model F is the result of the multiple steel plates in an assemblage of unresolved stresses of both tension and compression. Where deteriorating foam might make the assembly less tight and more prone to "rattle" I think that the thicker, stiffer foam adds to the internal stress and makes it both more solid and more alive.

The downside (after the difficulty of re-assembly has been overcome) is that the foam is forcing the plates apart at the center axis of their curvature. Unlike the smaller Fs, which only have tabs around the perimeter, the taller 122-key model has tabs down the center spine as well. While these should theoretically keep the plates tight, I don't think that they are always adequate, especially with firmer foam.

For that reason, I have settled on adding 3 screws down the center. I put them approximately between "5" and "F5", between "0" and "F10" and between "Enter" and "up arrow". It is easy to see where the traces run on the PCB, so make sure that you are drilling a blank field area. I drill in 2 operations such that the PCB is visible along with 1 plate the first time, to ensure that I am drilling a clear area, then I put the 3rd piece on and use the existing hole as an index. Make sure that the tabs are pushed to the fully closed position and do not allow the plates to slide while drilling.

These screws allow the plates to be pulled together tight along the innermost tangent of the axis of curvature and I crank them down fairly tight.

You can over-do it but you also get the opportunity to adjust it to your liking.

Size 4-40x1/2" (Imperial) or M3x8mm (metric) seems about right, and I use both steel and rubber washers if I can fit them in.

Allright I suppose I could be sure to make sure I am drilling into a blank area and then I could screw the bolts tighter or loosen them and then see if that affects the sound. Mine sounds really nice right now and the only thing that is slightly annoying is the spacebar. By the way Fohat, you drill when exactly? I had trouble figuring out when to when to drill the last time I saw your guide. Is it when you have the plates clamped and the tabs aligned already?

Also, do you think the board would be more solid if you added more bolts? Or would that be too risky?

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

You really think it might be the springs? They all seem the same size to me. I hope it is the tightness of the plates and not the springs because that means it pretty much cannot be changed if you wanted to.joc wrote: Ellipse - Yeah, the first one is crisper/louder in person.

I haven't done any restorations to either keyboard and they've never been opened. Here are a couple pictures that will hopefully give you an sense of what condition the foams are in (the 6110344 is on the bottom):

The foam that's sticking out of the sides is nondense, dry, and brittle. I don't think it's necessarily the bad condition of the foam that's causing the sound because I have another Model F (early 1985) that is crisper/clackier/louder with foam that's in good condition.

On both keyboards, the barrels in the a-s-d-f row have some play but the barrels in the number row don't have any play.

Both assemblies look like they're sandwiched as tight as possible. Also, upon closer inspection, it looks like the keys on both keyboards have about the same amount of travel distance. Here are some pictures of the springs that show that they stick out about the same distance on both keyboards (the 6110344 is first):

At first I was leaning towards the tightness of the sandwich being the driving factor that affects the feel/sound but now I think it might be the springs.

- fohat

- Elder Messenger

- Location: Knoxville, Tennessee, USA

- Main keyboard: Model F 122-key terminal

- Main mouse: Microsoft Optical Mouse

- Favorite switch: Model F Buckling Spring

- DT Pro Member: 0158

I do not really relate to the obsession over "sound"Redmaus wrote:

Allright I suppose I could be sure to make sure I am drilling into a blank area and then I could screw the bolts tighter or loosen them and then see if that affects the sound.

By the way Fohat, you drill when exactly? I had trouble figuring out when to when to drill the last time I saw your guide. Is it when you have the plates clamped and the tabs aligned already?

Also, do you think the board would be more solid if you added more bolts? Or would that be too risky?

My concern has always been feel. All these things that I do probably dampen the "rattly" "pingy" sound of a Model F.

I do all my mod work when the components are completely apart. For example, after drilling, I use a countersink bit to clean up the burrs on both sides of every hole (twirling it in your fingertips is probably enough), and I do it all before any painting of the plate (and, by the way, I recommend allowing the paint plenty of time to completely cure before putting the foam against it, to keep it from sticking). I wipe everything down spotless with with alcohol before I start any re-assembly.

You seem to be swinging back and forth between no bolts and many bolts. I can only relate my own experience and opinions. Feel free to experiment for yourself.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Allright, I think I will settle on the bolts that you used. 3 in the center. Wiping everything down sounds like a really good idea to me. That would make sure that nothing does not corrode or makes any imperfections in feel or weird sounding keys.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Bolts make the plates tighter together and make the keyboard as a whole more solid. That is my understanding of it. You could ask Fohat as he knows more that me about this. I might even just bail on it if I see the PCB once it has been opened. I don't know completely yet. I will probably stop talking about it now because I really can't tell if I am going to do it until I am ready to ANSI mod it.

- joc

- Location: The Lone Star State

- Main keyboard: IBM F104 (Unsaver) || IBM SSK

- Main mouse: Logitech M570

- Favorite switch: IBM Beam Spring

- DT Pro Member: -

Maybe? I think the springs might be affecting the feel/sound of the keyboards because the assemblies look like they're in otherwise similar condition from the outside. It looks like the plates and pan of both keyboards were sourced from different places because they have different finishes. I wouldn't be surprised if the springs were also sourced from different places. There seem to be a lot of factors that can affect the feel/sound of a Model F so I can't say for sure what's causing the difference without experimenting for myself.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Yeah, you are right there really is a lot of factors. I think the springs look the same, but that is just me. In another thread I saw, did somebody say they had tested that model M and model F springs were compatible?

- Touch_It

- Location: Nebraska, United States.

- Main keyboard: Unicomp Classic USB 103 key (work) IBM F 4704 107

- Main mouse: Logitech g502 Proteus Core

- Favorite switch: Buckling spring (yet to try Beam Spring)

- DT Pro Member: -

I think someone had/has tried that before but they aren't compatible. On another note There is a thread somewhere trying to find a manufacturer to order/create springs from.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

That would be useful. I know that you can already get extra model m springs from clickykeyboards.com

- fohat

- Elder Messenger

- Location: Knoxville, Tennessee, USA

- Main keyboard: Model F 122-key terminal

- Main mouse: Microsoft Optical Mouse

- Favorite switch: Model F Buckling Spring

- DT Pro Member: 0158

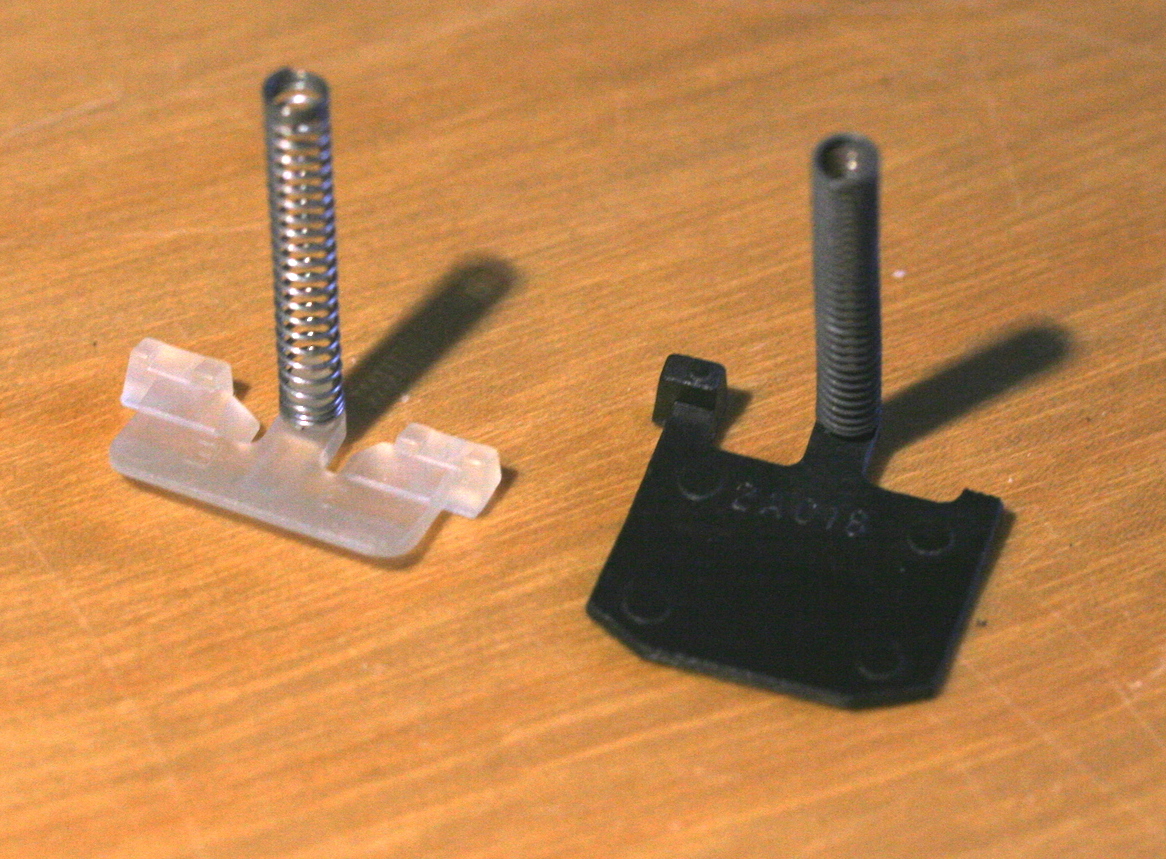

This should be very straightforward, but perhaps a picture is worth 1K words.

Red is foam attempting to push the plates apart, particularly at the center of curvature.

Blue is a screw pulling the plates back together at the center.

Red is foam attempting to push the plates apart, particularly at the center of curvature.

Blue is a screw pulling the plates back together at the center.

- Attachments

-

- f-122-plates.jpg (7.41 KiB) Viewed 5962 times

- fohat

- Elder Messenger

- Location: Knoxville, Tennessee, USA

- Main keyboard: Model F 122-key terminal

- Main mouse: Microsoft Optical Mouse

- Favorite switch: Model F Buckling Spring

- DT Pro Member: 0158

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

It wasn't really tested, I worded that wrong. OP in some thread was asking if they were compatible. There was a lot of mixed answers. Thats why I was unsure. So from the look of that image, it is a no. The model F spring is longer and thinner.

- fohat

- Elder Messenger

- Location: Knoxville, Tennessee, USA

- Main keyboard: Model F 122-key terminal

- Main mouse: Microsoft Optical Mouse

- Favorite switch: Model F Buckling Spring

- DT Pro Member: 0158

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Has a hammer or spring on any of your model F's ever failed and had to be in need of a replacement?

- fohat

- Elder Messenger

- Location: Knoxville, Tennessee, USA

- Main keyboard: Model F 122-key terminal

- Main mouse: Microsoft Optical Mouse

- Favorite switch: Model F Buckling Spring

- DT Pro Member: 0158

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

Allright, that is very good to know. I sure hope my springs will never be in need of a replacement. Or hammers.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

- Touch_It

- Location: Nebraska, United States.

- Main keyboard: Unicomp Classic USB 103 key (work) IBM F 4704 107

- Main mouse: Logitech g502 Proteus Core

- Favorite switch: Buckling spring (yet to try Beam Spring)

- DT Pro Member: -

It falls under multiple categories so no. Personally I would have opted for the workshop sub forum if doing work or photo sub forum for pics only but it also falls under keyboards lol.

- Redmaus

- Gotta start somewhere

- Location: Near Dallas, Texas

- Main keyboard: Unsaver | 3276 | Kingsaver

- Main mouse: Kensington Slimblade

- Favorite switch: Capacitative Buckling Spring

- DT Pro Member: -

- Contact:

OK, its just I see after I posted it, there were a lot of posts like that in the photos area. I also noticed no one replied to the post