I simply don't know and I'm sure someone here does. This isn't specifically about my dead OmniKey, but just in general.

If I took a random metal mounting plate, added some switches, and started hooking up wires and diodes, what's to stop the switches from popping off the plate?

Hand Wired N00b Question

- hellothere

- Location: Mesa, AZ USA

- Main keyboard: Lots

- Main mouse: CST2545W-RC

- Favorite switch: TopreAlpsHallEffectTopreAlpsHallEffectTopreAlps

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

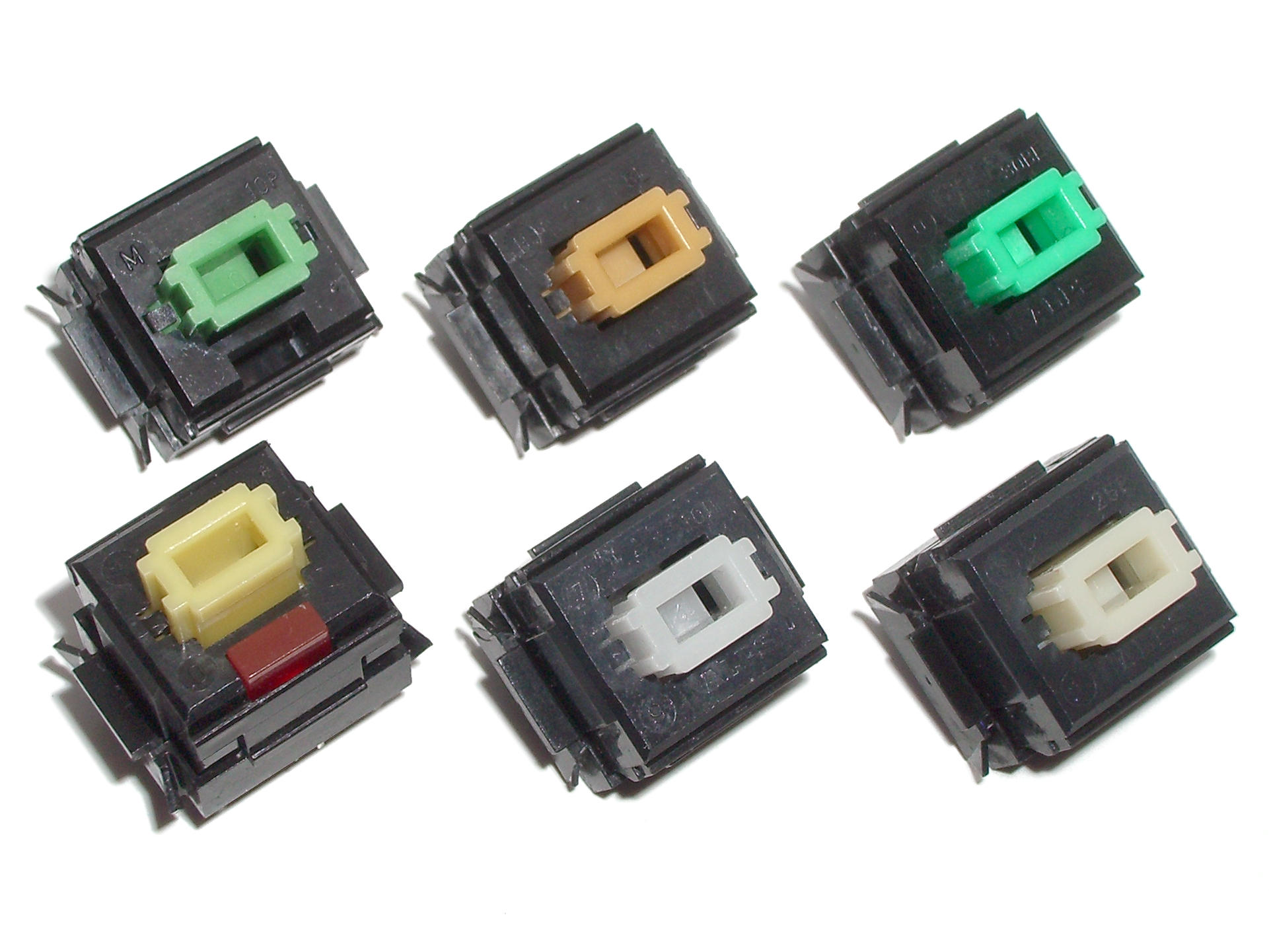

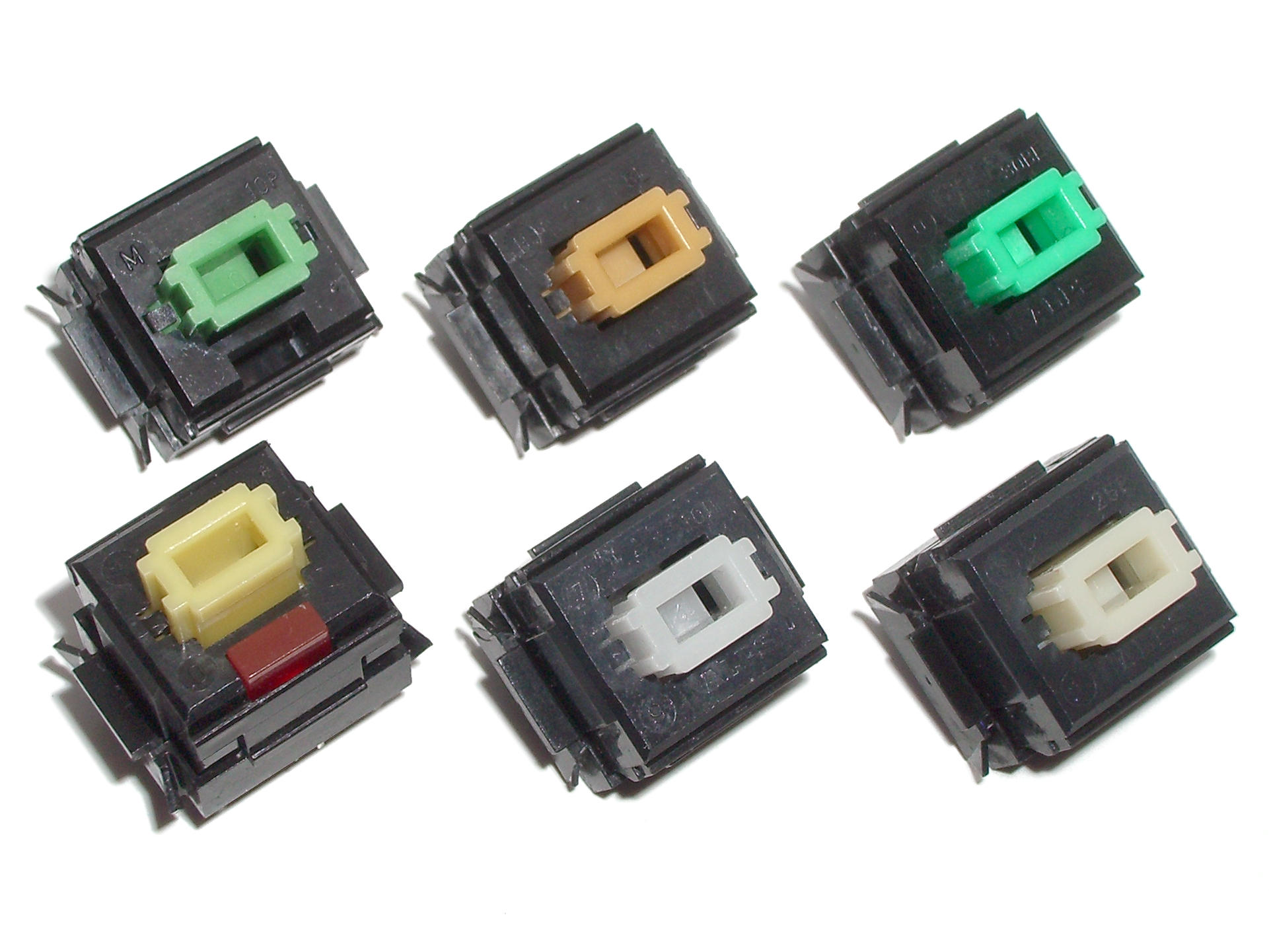

Alps switches have little clips on the side:

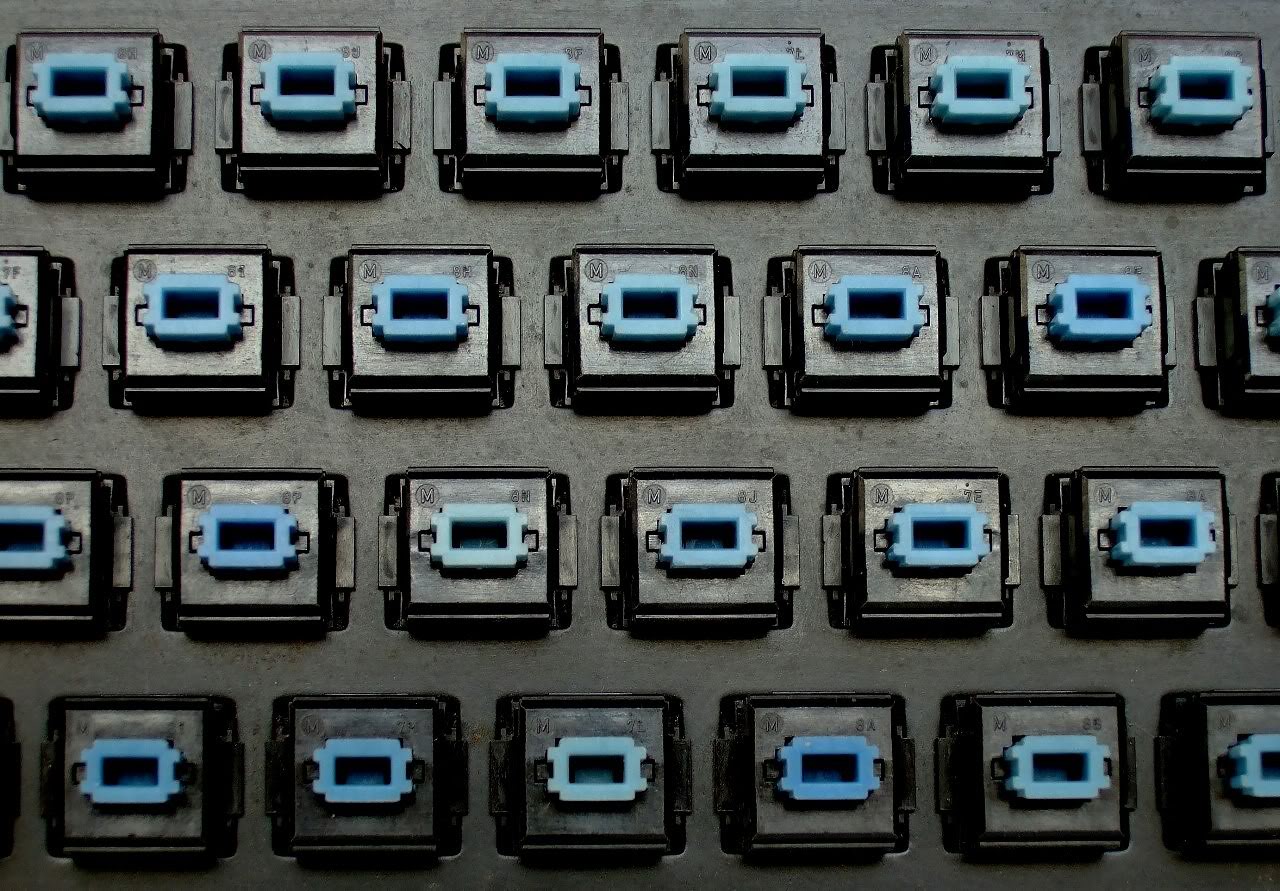

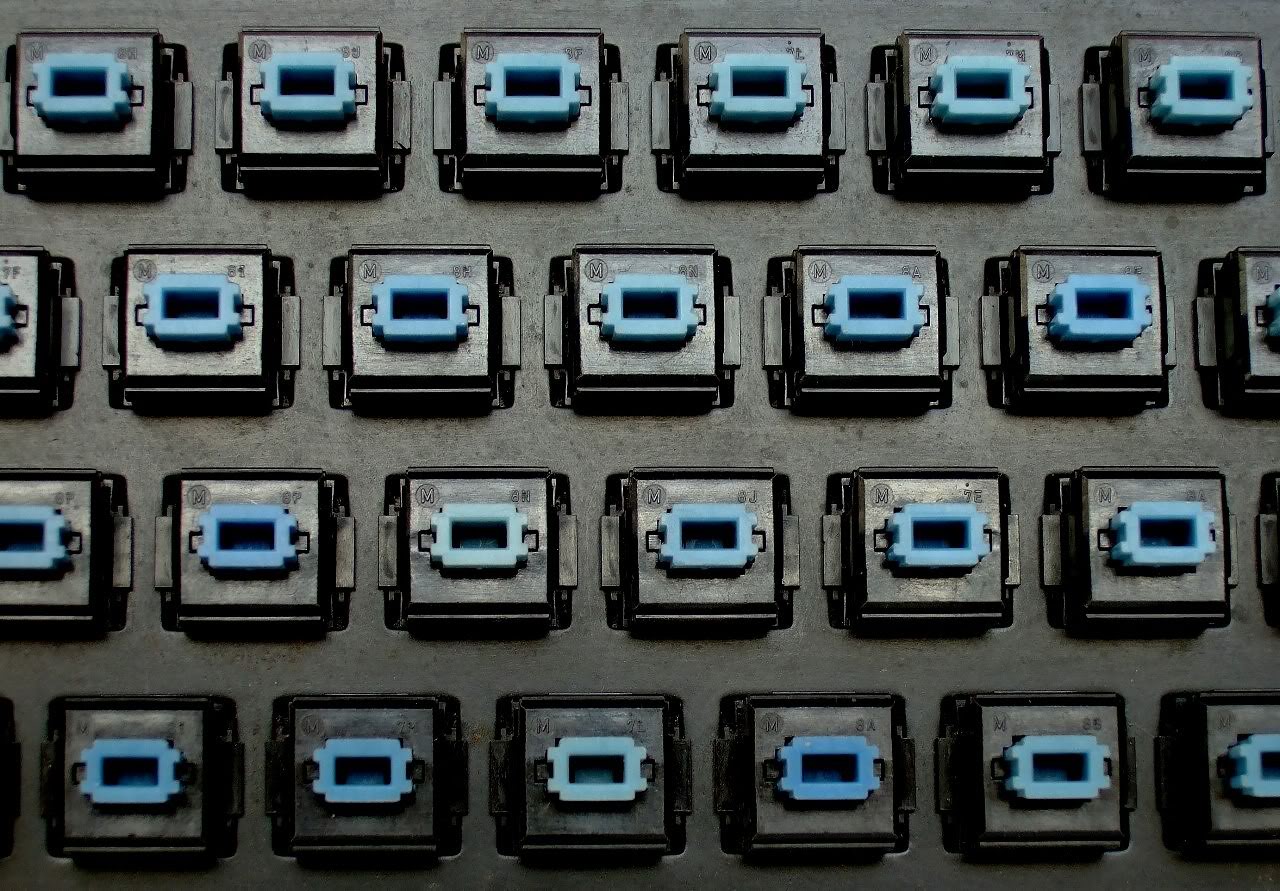

Which snap into the plate, like so:

MX is similar. They just click right in. No need for a PCB, structurally speaking; though it saves you a lot of wiring!

Which snap into the plate, like so:

MX is similar. They just click right in. No need for a PCB, structurally speaking; though it saves you a lot of wiring!

Not so keen on that word! Tolerances are real. Use someone’s proven design.

- hellothere

- Location: Mesa, AZ USA

- Main keyboard: Lots

- Main mouse: CST2545W-RC

- Favorite switch: TopreAlpsHallEffectTopreAlpsHallEffectTopreAlps

OK, more specifically, if I took an Alps switch and put it in an Alps metal mounting plate (etc.). Same for Cherry/Cherry clones.

Again, with Alps, at least, they don't clip in that well for me. It's been long enough on my refurbing a Cherry/Cherry clone, I don't remember how easily they come off a mounting plate IF said Cherry switches are mounted in a mounting plate and not just on a PCB.

Again, with Alps, at least, they don't clip in that well for me. It's been long enough on my refurbing a Cherry/Cherry clone, I don't remember how easily they come off a mounting plate IF said Cherry switches are mounted in a mounting plate and not just on a PCB.

- mmm

- Location: Denmark

- Main keyboard: 34-key split keyboard / F122

- Main mouse: Mx Ergo / Trackpad

- Favorite switch: Cap bs

For me it has usually required a lot of force to get those alps out of the plates - but the same can be said for the keycaps.

Some people (hot) glue the switches to the plate to make them stick.

Another option, if you do have the PCB around, is to use it for support. Either cut all traces, or piggyback your handwire on the existing matrix.

Some people (hot) glue the switches to the plate to make them stick.

Another option, if you do have the PCB around, is to use it for support. Either cut all traces, or piggyback your handwire on the existing matrix.

- Muirium

- µ

- Location: Edinburgh, Scotland

- Main keyboard: HHKB Type-S with Bluetooth by Hasu

- Main mouse: Apple Magic Mouse

- Favorite switch: Gotta Try 'Em All

- DT Pro Member: µ

A bad plate will fit badly. I’ve an Alps one someone here made for me many years ago which is lousy and I never could use for a 60%. Switches won’t even sit in it for storage!

A good plate will hold the switches just nicely, as mmm said. Tolerance is real.

A good plate will hold the switches just nicely, as mmm said. Tolerance is real.

- snacksthecat

- ✶✶✶✶

- Location: USA

- Main keyboard: SSK

- Main mouse: BenQ ZOWIE EC1-A

- DT Pro Member: 0205

- Contact:

Swill made this excellent tool which takes a Keyboard Layout Editor layout json and spits out a perfectly drawn plate with the proper cuts.

Deskthority thread on the topic:

viewtopic.php?t=10228

Just keep in mind that there are some wildcard factors when it comes to laser cutting materials. Most notably, you need to account for "kerf", which is described in the SwillKB docs as:

http://builder-docs.swillkb.com/features/#kerf

Deskthority thread on the topic:

viewtopic.php?t=10228

Just keep in mind that there are some wildcard factors when it comes to laser cutting materials. Most notably, you need to account for "kerf", which is described in the SwillKB docs as:

http://builder-docs.swillkb.com/features/#kerf

I messed this part up in my first Alps plate and it's not safe to pull a keycap off 'cuz the switch will come out with it!Kerf

The kerf feature allows you to account for the kerf of the cutting tool when the part is being fabricated. Kerf is the width of the material removed by a cutting tool. If you do not account for kerf, the part will be smaller than expected by 1⁄2 the tool’s kerf value on all cut sides. The kerf is calculated along the cut line, so 1⁄2 will be inside the line and 1⁄2 will be outside the line. So for example, if the kerf of a cutting tool is 0.2mm, that means that an extra 0.1mm will be removed from the plate when it is cut (the other 0.1mm is removed from the off cut). I account for this, so if the kerf is set to 0.2mm, the resulting 14mm square hole would be drawn as a 13.8mm square. Keep in mind that the different processes will have different values for kerf, so check with the manufacturer. Also, keep in mind that the type of material and its thickness plays a role in the width of the kerf.

If you order your job through the builder.swillkb.com tool, then the parts will be redrawn in the tool with the kerf value optimized for the selected fabrication vendor.