Membrane keyboard

| This article requires additional photographic illustration — add a proper membrane keyboard (such as Sinclair ZX80 or Atari 400), add prong over membrane and hammer over membrane illustration |

Membrane keyboards place the matrix circuitry onto thin sheets of plastic, called "membranes".

Contents

Description

Membrane keyboards use plastic sheets for the matrix traces. This is a cost-effective alternative to printed circuit boards. Exposed pads within these traces allow for switching. A conductive object can be placed between the pads to bridge the gap, or pads on separate layers can be brought together under pressure given that the membrane sheets are highly flexible.

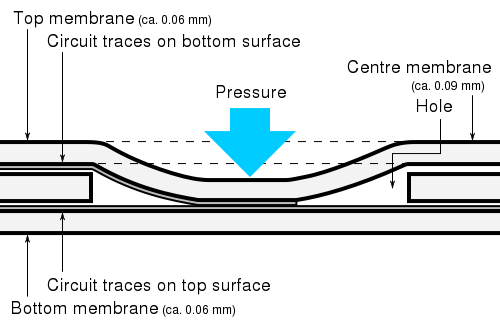

Examination of one keyboard showed that the top and bottom membranes are around 0.06 mm thick, while the centre spacer layer is around 0.09 mm thick. This is around the same thickness as 80 gsm paper.

The membrane layers must be kept flat; traditionally they are backed by a backplane of steel but in cheaper constructions the rear case will support the membranes directly. Because membranes are flexible the backplanes can be curved or consist of multiple parts at different angles and/or heights with a single membrane/stack. Extensions of membranes are sometimes used as ribbon cables connecting the matrix traces to the keyboard controller.

History

Membrane keyboards are not a new idea. Datanetics developed a complex membrane assembly design in 1968, as found in US patent 3594684 (filed 1969, issued 1971). This design used many more layers than are found in modern keyboards, and included gold plating for reliability. Instead of continuing down this path, Datanetics decided to place the membrane inside the switch, a design which became the discrete DC-50 series.

Mitsumi KSD Type has been found in an Atari 800 computer dated December 1982. KSD Type is a PCB–membrane hybrid, using a PCB for the stationary portion of the circuit, and two membrane layers above that for the movable portion of the circuit (trace layer and spacer layer).

D'Milo Hallerberg reported that Hi-Tek Corporation were developing membrane keyboard technology around the time that they were acquired by NMB's parent company Minebea, ca. 1983.[1] It is possible that this went on to become the membrane version of the RT-101 series. IBM introduced the IBM Enhanced Keyboard in 1985, bringing buckling spring and membrane technology together; this design was filed in 1983 as US patent 4528431, granted in 1985.

Membrane technology did not become commonplace until the 90s. BTC was using rubber dome keyboards in the 90s, but even in 1994 with the BTC 51X9 series was still using a PCB for the matrix. Apple's first full-size membrane keyboard was the AppleDesign Keyboard, introduced in 1994 to replace the mechanical Extended Keyboard II; for cheaper machines, the membrane-based Apple Keyboard II had already been around since 1990. By the 2000s, rubber dome over membrane keyboards were a given.

Actuation

Pressure actuation

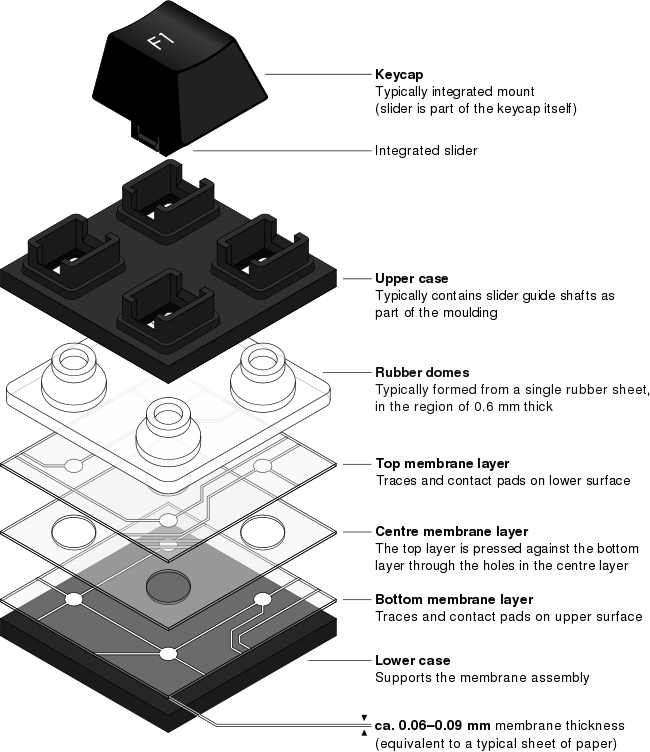

Pressure-actuated membrane keyboards use two or three membranes. Electric current is conducted between exposed pads in the top membrane when it is pressed down against the bottom membrane. The bottom membrane does not move, and in rare cases a PCB is used instead of the third membrane. The top and bottom layers are held apart by a spacer membrane with one hole per key; pressing a key pushes a small portion of the top membrane down through one of these holes and brings it in contact with the bottom membrane.

Very little pressure is required to press the membrane sheets together, and it is unlikely that anyone would feel the plastic flex downwards by around 0.09 mm; with the rubber domes removed, the membrane layers simply resemble a "futuristic"-looking solid-state capacitive panel. A rough test using five pence coins (officially 3.25 g each) demonstrated actuation with between four and six coins, suggesting 13 to 19.5 g actuation force; the same keyboard (a Chicony-made Viglen KU-0325) tested with coin stacking as having between 65 and 75 g actuation force, giving a very approximate indication of the relationship between dome force and membrane force.

There are multiple methods for applying pressure to the top membrane, as explained below.

Rubber dome over membrane

Rubber dome over membrane is the most common type of keyboard design manufactured today, for both desktop and notebook computers. Notebook keyboards typically use scissor switches, which are a compact derivative of rubber dome over membrane.

A rubber dome is placed above each pair of contact pads; this functions as the return spring as well as providing a soft surface to transfer force onto the membranes. Rubber dome over membrane keyboards typically have very little overtravel; it is necessary to bottom out on every keystroke.

The terms "membrane" and "rubber dome" are frequently conflated, owing to how typical keyboards utilise both. However, membrane keyboards do not require rubber domes, and rubber domes do not require membranes: each can be used with suitable alternatives.

The rubber domes can be left loose (as found in Alps and Silitek keyboards), glued to the top membrane (as found in NMB keyboards), or most commonly, moulded from a single sheet.

Discrete domes in an Alps-made AppleDesign Keyboard

Membrane assembly of NMB-made AppleDesign Keyboard

Fujitsu FKB4700 dome sheets

Spring over membrane

In some older keyboards, a spring is placed inside the slider. As the key is depressed, this spring makes contact with the top membrane. After sufficient pressure is applied, this spring deforms the top membrane enough to make the switch. As the spring can be compressed further, overtravel is possible.

Spring-over-membrane switches typically use a second device to provide additional force; this will normally be a second helical spring, but buckling rubber sleeves have also been used, such as in the Fujitsu Libertouch. Omron vase spring does use a single metal spring.

Membrane pressure springs in an Oriental Tech OK-100M

See: Spring-over-membrane switches

Prong over membrane

Prong over membrane, or single spring over membrane (depending on your definition of "spring"), is a cheaper alternative to spring over membrane. The role of motion reducer is changed from being a helical spring to a flat plastic prong. These prongs are not discrete; they are part of the same moulding as the plate that holds the sliders or retains the integrated mount keycaps. In these keyboards, the return spring sits over the prong; as the key is depressed, the prong moves downwards proportionally at a lower rate than the switch until it is pressing the membranes closed.

See: Prong-over-membrane switches

Hammer over membrane

Spring-over-membrane switches provide a smooth increase in force against the membrane. Hammer-over-membrane designs strike the membrane instead. The term is something of a misnomer, as it is typically used to refer to IBM buckling spring switches, which use a small flat paddle to provide the impact. The Acer switch however concentrates the force into a small circular area on the end of a pivoting bar, which holds the bottom end of the return spring. The exact specifics of the operation have not been studied.

See: Hammer-over-membrane switches

References

- ↑ Conversation with D'Milo Hallerberg