Keystroke sensing

| This article requires additional photographic illustration |

Contents

Overview

Keyboard keys can be thought of as a combination of two principles: a method to allow the host device (e.g. computer) to sense that a key was pressed, and a method of operating the switch. These concepts are distinct, although they do overlap. Switch operation covers ways to make the key spring back up when released, and when desired to generate a sound or a change in feel to indicate to the operator that the keystroke was registered.

Fundamentally, a keyboard needs to sense keystrokes. Trade-offs between manufacturing cost and longevity have led to a number of different approaches. Such approaches have been collectively termed "contact mechanisms", but since many designs do not rely on physical switch contacts this term is a misnomer, and "sense method" is more appropriate.

Various combinations of the two principles can be combined. For example, rubber domes have been used in conductive, magnetic valve and capacitive switches; in conductive switches they form part of the physical switching mechanism, while in electromagnetic switches they simply serve to return the key and provide tactility.

The different methods of sensing keystrokes are detailed below.

Conductive

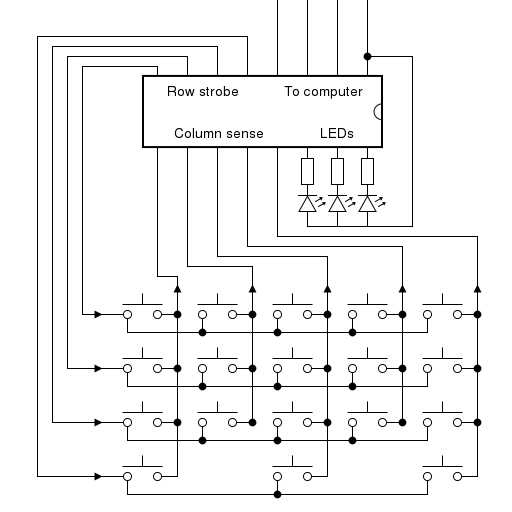

The majority of computer keyboards work on the principle of switching electric circuits on and off. To register a keystroke, a circuit pathway is connected. The keyboard can be modelled as a grid (matrix) of simple push-button switches:

While this is simple in principle, there are various ways to achieve this aim. Further, in reality this simplistic arrangement is not practical. Conductive keyboards permit current to flow the wrong way through the circuit, leading to ghosting: when certain combinations of keys are held, the computer believes that additional keys are being held. Conductive keyboards typically use filtering logic to detect and block keystrokes before this happens, or employ diodes at each key to prevent the incorrect current flow. A few keyboards, such as the BTC 51X9 series, do take the simplistic approach and suffer from ghosting.

Metal contact

Behind membrane keyboards, the second most common switch type is metal contact. Within the switch are two pieces of metal that are pressed together to conduct current. In most cases, these contacts are also the switch terminals, but in cases such as Futaba linear switches, the terminals are separate parts. Generally, there is one stationary contact made of thicker, inflexible metal, and one movable contact made of a springy metal such as phosphor bronze. Depending on the design, the slider either presses the contacts together (typical in Alps clone switches) or separates them until it is depressed (such as with Cherry MX switches). In some cases, such as with Hi-Tek Series 725, both terminals are flexible, and the contacts may be identical, as they are the PED keyswitch, to reduce the number of different parts required.

The design of the movable contact varies greatly; it can be a leaf spring (as with Cherry MX), a foil sheet (as with Alps SKCL/SKCM series), and a wire spring, as with MEI T-5 series.

Hua-Jie AK series switches, with one dismantled to reveal the contacts

Fully disassembled Alps switchplate with foil contact

Cherry MX contacts, which are also the switch terminals

Mitsumi miniature mechanical contacts, held open by the slider

Sealed contact assembly from a Futaba complicated linear switch

See: List of metal contact switches

Metal leaf

Metal leaf is a subset of metal contact switches where the movable contact is a leaf spring. While this covers most switch types, there are many exceptions, some of which are described above.

Membrane

Membrane keyboards contain thin plastic sheets (ca. 0.06–0.09 mm thick) with exposed electrical traces. Typical designs use either one or three membrane sheets. Current is passed either by bridging traces with a conductive object (typically some form of carbon-impregnated silicone pad) or by flexing one membrane to press part of it against another, allowing current to transfer between traces.

See: List of membrane switches

Reed

A reed switch consists of two metal contacts, hermetically sealed and usually with some inert gas inside a glass envelope. The slider pushes a magnet down in front of the reed capsule. In a normally open switch, the magnetic field causes the reed contacts to become attracted to each other and to make contact; the contacts are themselves not magnetised. The reed switch mechanism was invented in 1936 by W B Ellwood at Bell Telephone Laboratories.

Reed switches support both normally open and normally closed operation. Hysteresis is also a standard feature; the degree of hysteresis present depends on the specification. Latching reed switches require alternating magnetic polarity to cycle the switch.[1]

The reed capsule can be orientated in a number of ways. Fujitsu and Omron B2R series switches have the reed capsule orientated vertically, which demands a tall switch to contain it. To save space, Clare/Pendar low-profile switches have the reed capsule arranged diagonally in the vertical plane, while FR Electronics, IZOT and Unitra Dolam opted to place it horizontally across the bottom of the switch. Fujitsu also used the horizontal arrangement.

Although reed switches are metal leaf contact switches, here they are considered separate from all other forms of metal contact switch, even those with sealed contact assemblies such as Futaba complicated linear, because the contacts are operated magnetically instead of using physical force.

Clare-Pendar Series S880, opened

Fujitsu Magnetic Reed and Omron B2R series are fairly different in appearance, but the reed modules in each are very similar:

See:

- List of reed switches

- YouTube — Actuating distances of Reed Switches having different Release AT (Drop-out) (depicts different amounts of hysteresis)

- YouTube — How does a bi-stable / latch reed sensor work?

Electromagnetic

While all full-travel keyboards require moving parts to function, conductive switches have extra moving parts that wear out with use. Switch lifetime can be increased by replacing the physical switch contacts with electromagnetism. In addition to greatly improved longevity, electromagnetic sensing also significantly reduces the friction in the switch feel compared to metal leaf switches, as the slider is not rubbing against movable switch contacts.

Capacitive

A capacitive contact mechanism makes use of a property of capacitors, that their capacitance is related to the distance between the plates that make up the capacitor. A capacitive keyboard switch moves a conductive object towards a pair of pads on the PCB, which are connected to a signal generator. Capacitive contacts have a long expected lifetime, but are also quite expensive and have thus fallen out of popularity for general purpose usage. Capacitive keyboards also have the advantage of not suffering from ghosting due as they are not dependent on the flow of current through the contacts. They are however sensitive to contamination affecting the capacitive sensing, but usually this can be resolved by cleaning the switch. Capacitive sensing lives on as the basis of most touch screen and trackpad technology used today.

IBM made use of capacitive sensing in beam spring and capacitive buckling spring keyboards, both very highly regarded designs. The most common implementation is foam and foil, where the movable part of the variable capacitor is a foil disc placed onto the bottom of a foam pad (added to provide overtravel). BTC foam and foil and Key Tronic foam and foil are the most commonly occurring foam and foil implementations.

Topre, with their very long-standing rubber dome-based Topre switch, was left as the only known manufacturer of mainstream capacitive keyboards by the 2000s, but more recently, their switch design has been copied, with the Noppoo capacitive switch being the first to be recognised.

Key Tronic foam and foil modules

BTC 5100 foil discs (top of keyboard upside down)

Noppoo capacitive: variable capacitor formed from a conical spring over dual PCB pads, under a rubber dome sheet

See: List of capacitive switches

Hall effect

Hall effect keyboards use a solid state sensor (in a microchip found inside each switch) to detect the movement of a magnet by the potential difference (voltage) that the magnet creates across a wire. A typical implementation of a Hall effect switch consists of a linear switch which has a magnet attached to the slider, whose movement when the key is pressed actuates the switch. They are extraordinarily reliable, with an expected lifetime measured in billions of key presses. However, they are too expensive for general use, and are usually reserved for military and aerospace applications.

Hall effect keyboards use discrete switches just as with most metal contact keyboards, but the switch modules typically have four legs instead of the two or three in metal contact switches. Four-leg switches are good indication of either Hall effect or magnetic valve.

Honeywell is by far the best known manufacturer of Hall effect keyboard switches and switches through their Micro Switch division. Similar switches were also made in Eastern Europe during the Soviet era, often copies of Honeywell's switches. RAFI in Germany still manufacture their long-standing RS 76 C series of Hall effect keyboard switches.

Hall effect switches made a comeback because of Wooting Two HE keyboards with Lekker switches and their rapid trigger and adjustable actuation point features. Starting from 2023 there are dozens of keyboards being manufactured with hall effect switches, the most prevalent being Gateron magnetic switches.[2]

Micro Switch SD Series switches

See: List of Hall effect switches

Magnetic valve

Magnetic valve keyboards operate by controlling the flow of electrons using wire loops and a ferrite core. As current flows around one loop, it converts into a magnetic field generated inside the ferrite core. The movement of the magnetic field causes a flow of electrons in the second loop. To stop the flow of electrons, the magnetic field around the ferrite is stopped. This can be done by using a permanent magnet that has a magnetic orientation in another direction. Or by moving the ferrite far enough away from one of the loops that it can no longer generate sufficient current to be detected by the keyboard controller.[3]

Magnetic valve keyboards can be fully or partially discrete, and in such cases, as with most Hall effect switches they have four legs. Where the wire loops are part of the PCB (as with ADI keyboards) this is itself a distinguishing characteristic.

ITW, ADI and Nixdorf have used magnetic valve switches.

See: List of magnetic valve switches

Inductive

Inductive keyboard switches are built using an induction loop. The induction loop generates a magnetic field. To complete the circuit, and register a keypress, a metallic object is placed inside the loop. The presence of the metallic object will increase the overall current flowing through the wire which can be detected by the controller.

Inductive switches are common but the only known keyboard switch example was built by HP for one of their function generators in the 1970s.

See: List of inductive switches

Optoelectronic

Optoelectronic keyboards use a light source (usually infrared), and a light detector (e.g. photo-resistor) to detect the presence of a key press. In known keyboards this is done by breaking the line between the light source and detector, and registering the change. These switches are highly reliable due to their non-contact nature, but often quite susceptible to dust if designed improperly.

It should also be noted that patents for keyboards exist where varying powers or different wavelengths of light are used to detect different keystrokes. However, none of these switching mechanisms have been seen in actual keyboards.

Collimation and Burroughs have used optoelectronic switches. Optoelectronic switches were used often when converting typewriter interfaces into computer data terminals.

Optoelectronic sensing has been reintroduced, with designs such as the A4Tech Bloody B640 (in switches styled after Cherry MX) and the Adomax Flaretech.

Burroughs Opto-Electric LEDs and photoresistors

See: List of optoelectronic switches

Acoustic

Acoustic keyboard switches using an acoustic transfer medium attached to one or more transducers that convert vibration into voltage changes (think microphone). Each switch has a unique position on the acoustic transfer medium. When a key is pressed, the switch strikes the acoustic transfer medium. Based on the shape and length of the acoustic transfer medium, the controller can easily determine which key was pressed using set patterns. It is unknown whether or not acoustic keyboards support NKRO.

Smith Corona has used acoustic switches in their electric typewriters.

References

- ↑ RRE — Reed Switch and Reed Sensor FAQ!

- ↑ List of hall effect keyboards

- ↑ HaaTa's description of ITW Magnetic Valve — Post