Difference between revisions of "Double-shot moulding"

m (Text replacement - "Honeywell Hall Effect" to "Micro Switch SD Series") |

(→Current: Added Devlin Q series image) |

||

| Line 29: | Line 29: | ||

===Current=== | ===Current=== | ||

====Devlin==== | ====Devlin==== | ||

| − | [[Devlin]]'s [[Devlin Q series|Q series]] keycaps are available in both double-shot and engraved forms. | + | [[Devlin]]'s [[Devlin Q series|Q series]] and [[Devlin K series|K series]] keycaps are available in both double-shot and engraved forms. |

| + | |||

| + | <gallery widths=250 heights=187> | ||

| + | File:Devlin Q series -- double-shot 1.jpg | Devlin Q series | ||

| + | </gallery> | ||

====GMK==== | ====GMK==== | ||

| Line 39: | Line 43: | ||

====RAFI==== | ====RAFI==== | ||

| − | |||

| − | |||

<gallery widths=250 heights=187> | <gallery widths=250 heights=187> | ||

File:RAFI RS 74 M double-shot keycaps.jpg | RAFI RS 74 M keycaps from a [[Neve Necam 96]] keyboard | File:RAFI RS 74 M double-shot keycaps.jpg | RAFI RS 74 M keycaps from a [[Neve Necam 96]] keyboard | ||

Revision as of 00:57, 31 March 2017

Double-shot moulding, double-shot, dual-injection moulding, two-shot moulding or insert moulding is the process of moulding plastic around a preformed metal or plastic insert. This has been a popular process to create very durable keycaps in the past. Recently, the process has become more rare and is usually only used on separate keycap orders from companies such as Signature Plastics or on special keyboards used as military or medical equipment. There currently is no mainstream keyboard being produced that still uses double-injection moulded keycaps. Until early 2010, Cherry still offered double-shot moulded keycaps as an option for their POS and special-order keyboards. Production ultimately stopped and all keyboards with double-shot moulded keycaps were called off. November 2012, it was announced that German company GMK had acquired the original tooling and moulds[1]. In December 2012, EliteKeyboards offered the first GMK product in the form of a double-shot Cherry Escape key[2].

Contents

Attributes

Advantages

- Maximum contrast lettering: the legends are bold and vibrant and pure in tone, with smooth edges and uniform colouration.

- Zero wear: the legend will never wear, as it runs right through the surface of the keycap.

- Colour freedom: the keycap and legend can each be of any colour desired: this lends itself well to custom keycaps where a wide range of colours is highly desirable.

- Feel: the legend and the keycap are one, and the legend cannot be felt while typing.

Wear resistance test using two keycap types from the same Tulip ATK 030244 and a sharp knife

Disadvantages

- Cost and availability: the process of building moulds for each and every legend is an expensive process compared to making one mould per row profile and adding the legends afterwards on demand, especially considering manufacture for the wider international market where even simple letters such as "A" move between row profiles (e.g. QWERTY vs AZERTY, QWERTY vs QWERTZ).

- Single colour: typical double-shot processes restrict the keycap to a single legend colour, although it is possible to inject further colours and this has been done.

- Low resolution: double-shot legends are limited to low resolution designs with broad strokes and rounded corners. The range of typefaces and symbol designs available with pad printing and dye sublimation cannot be achieved with double-shot, as the moulding process doesn't support the fine detail and sharp edges that those processes afford.

- Gloss and yellowing: Double-shot moulded keys are made from ABS plastic because most other plastics shrink too much in the moulding process. ABS may yellow over time, and is not as hard as PBT plastic. The texture of PBT keycaps will remain longer than the texture of ABS keycaps - the ABS keycaps get glossy after extended usage. Because of this, PBT keys with dye sublimated legends are regarded by many as an even better alternative, although dye sublimation has its own set of disadvantages and limitations, most notably it cannot be used to print light legends on dark keycaps.

Production

As the name suggests, double-shot moulding is a two step process. In the first step, the legend or graphics to be placed on the keycap, are moulded in plastic[3]. The plastic insert, resulting from the first step, is then placed in another mould, while plastic is inserted under heat to combine both moulds to a single piece keycap.

Despite the name, the moulding process is not restricted to two colours: triple and quadruple[4] shot keycaps exist, where two or three different legend colours are present on a single keycap. The use of more than three colours is however quite rare. More commonly, where multiple legend colours are required, the additional colours are provided using pad printing (dye sublimation would be unsuitable with the ABS material used in double-shot moulding). This is especially true where the extra text is printed on the front of the keycap, such as with NeXT keyboards.

Manufacturers

Current

Devlin

Devlin's Q series and K series keycaps are available in both double-shot and engraved forms.

GMK

German manufacturer GMK bought Cherry's double-shot tooling and have resumed manufacture of Cherry-profile double-shots.

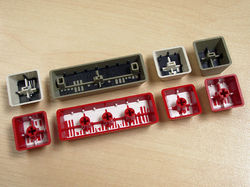

GMK keycaps from Elitekeyboards and from 2013-2014 group buys

RAFI

RAFI RS 74 M keycaps from a Neve Necam 96 keyboard

Signature Plastics

Signature Plastics took over the keycap manufacturing of Comptec. Notably, all various found so far do not show the coloured stripes typical of more prominent brands. Their keycaps are similar to those made by Futaba.

Assorted novelty keycaps

Tai-Hao

Tai-Hao are a long-time manufacturer of double-shot keycaps, both Cherry MX mount and Alps mount. Their widely-used standard keycap series is still manufactured to this day, and has been extended to cover PBT keycaps. Tai-Hao keycaps were used by brands including Ortek, Focus Electronic and Northgate Computer Systems.

Assorted 2013 group buy keycaps

Cherry MX mount rubber WASD gamer keycaps

Historical

Alps Electric

While Alps are better known for the dye sublimated keycaps used in Apple keyboards, Alps also produced distinctive double-shot keycaps. Alps are one of the companies whose moulding process did not show stripes of colour within the underside of the keycap. Many double-shot Alps keycaps feature a curious pattern of bars and square holes that aids in their identification.

Alps double-shot keycaps are likely to have been produced in-house.

Alps double-shot keycap from a NeXT keyboard (Alps SKCM Black)

Assorted IBM 5556 keycaps, top view

Cherry

Cherry produced double-shot keycaps in-house, they discontinued the manufacture of double-shot keycaps in 2011. The tooling was sold to GMK, who resumed manufacture of the parts.

Tops (keycaps from a 1997 G80-3700HAU)

Comptec

Comptec were one of the world's leading keycap manufacturers, whose keycaps have been found in a large variety of equipment including the Acorn BBC Microcomputer and Wyse terminal keyboards. Comptec USA became Signature Plastics, who remain a very prominent double-shot manufacturer. Tall Comptec keycaps often feature an inner step that appears to be specific to their manufacturing process.

Acorn BBC Microcomputer spherical keycaps, from the AWC/Futaba keyboard

All three Comptec BBC Micro keycap types: Philips keyswitch, SMK vintage linear, Futaba simplified linear

Futaba

Little is known about Futaba keycaps.

Futaba keycaps from the NEC PC-8801mkII

Micro Switch

Micro Switch are notable for their very thick, sturdy keycaps.

Micro Switch SD Series keycaps

SMK

SMK double-shot keycaps have varied in design over time. All their keycap styles have in common a completely solid first shot, without striped bands of colour. Older keycaps (from SMK vintage linear keyboards) had a large first shot (giving thick keycaps), while newer keycaps for SMK second generation switches reduced the size of the first shot. It is not known whether they were produced in-house or outsourced.

Acorn BBC Microcomputer switches and keycap

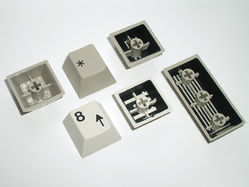

Apple M0110A keycaps

Tulip ATK 02.01.01 keycaps

External links

- WASD keyboard — keyboard with double-shot keycaps

- ちゃたりたいね — Yamaha QX3 Sequencer keyboard — quadruple-shot keycaps (Japanese)

References

- ↑ Deskthority — German company GMK does MX 2shots

- ↑ Deskthority — EK selling authentic cherry doubleshot esc

- ↑ Deskthority — Visited Signature Plastics for real

- ↑ Deskthority — Quad-shot keycaps?